A Dynamic Scheduling Method for Flexible Job Shops Considering the Availability of Machining Equipment

A flexible operation and dynamic scheduling technology, applied in the direction of comprehensive factory control, general control system, control/adjustment system, etc., can solve problems such as abnormal status of machining equipment, affecting normal operation of scheduling, and uncertain processing time, so as to ensure timely Performance and stability, improve dispatching operation efficiency, and improve the effect of responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

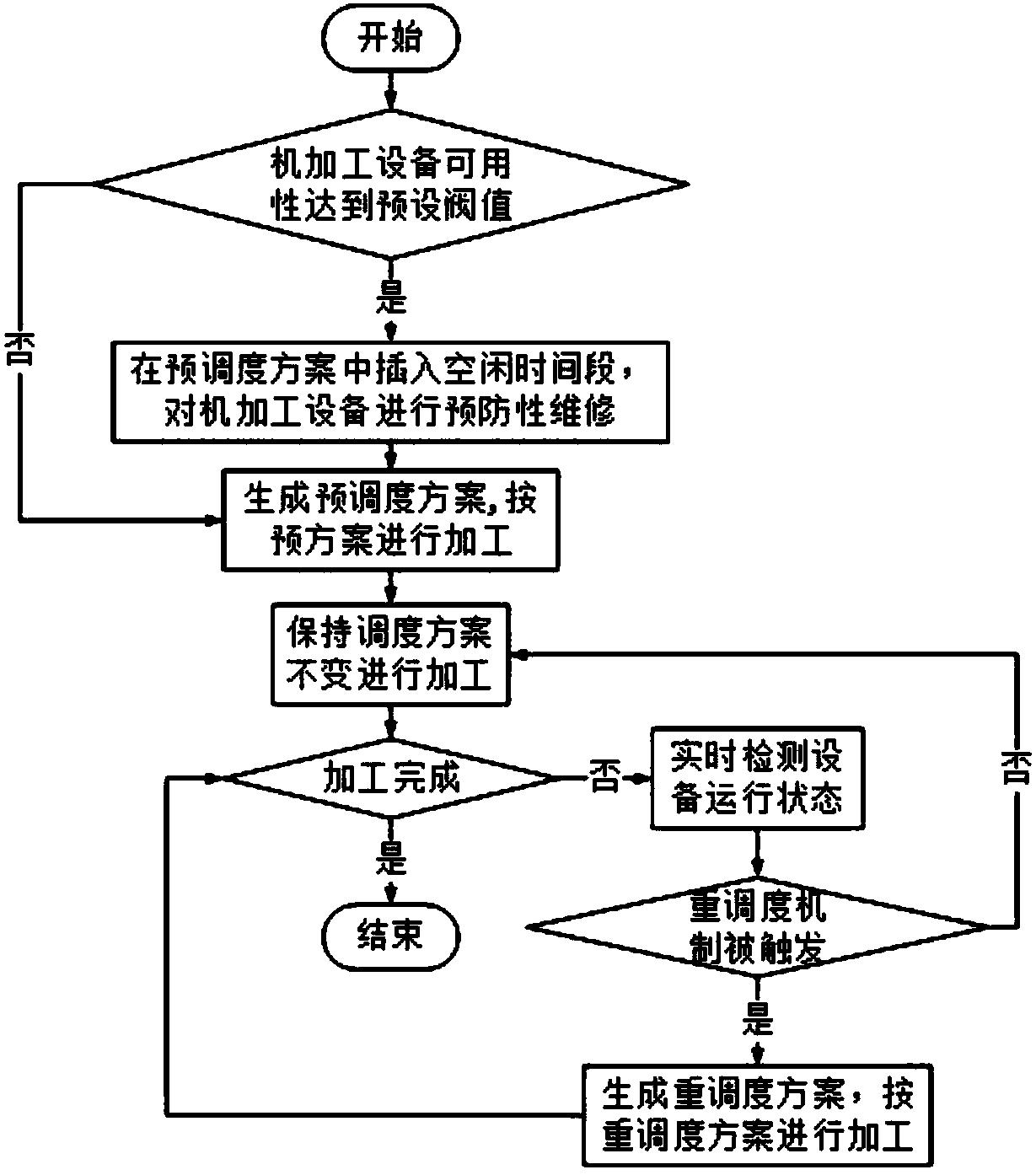

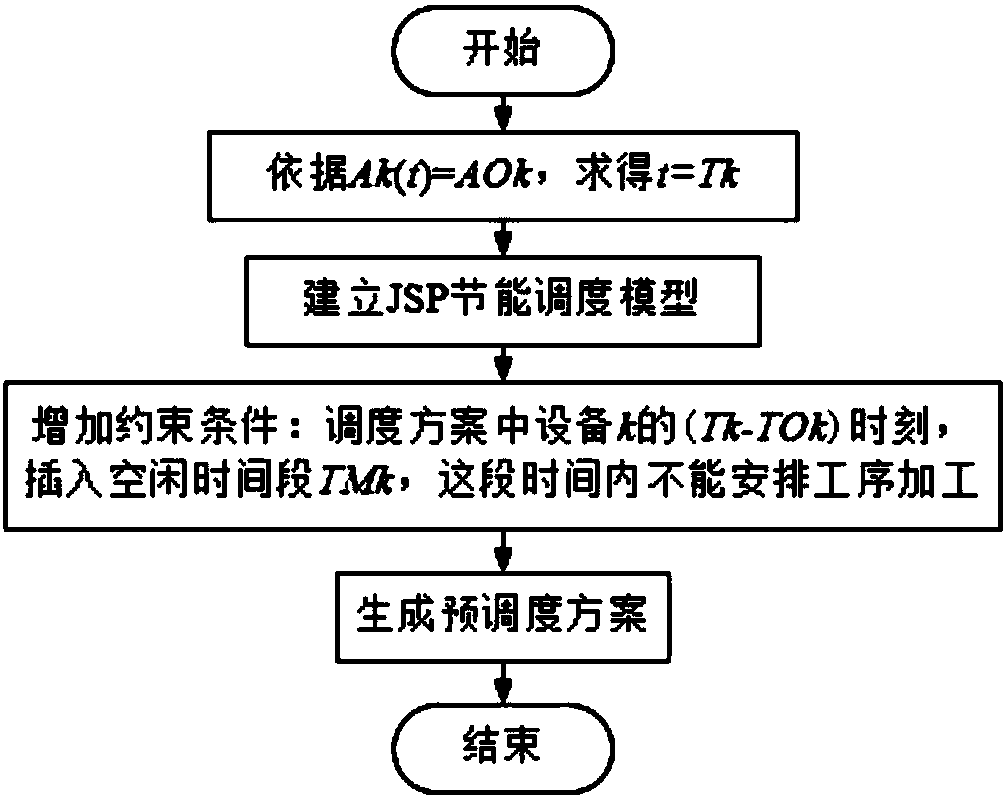

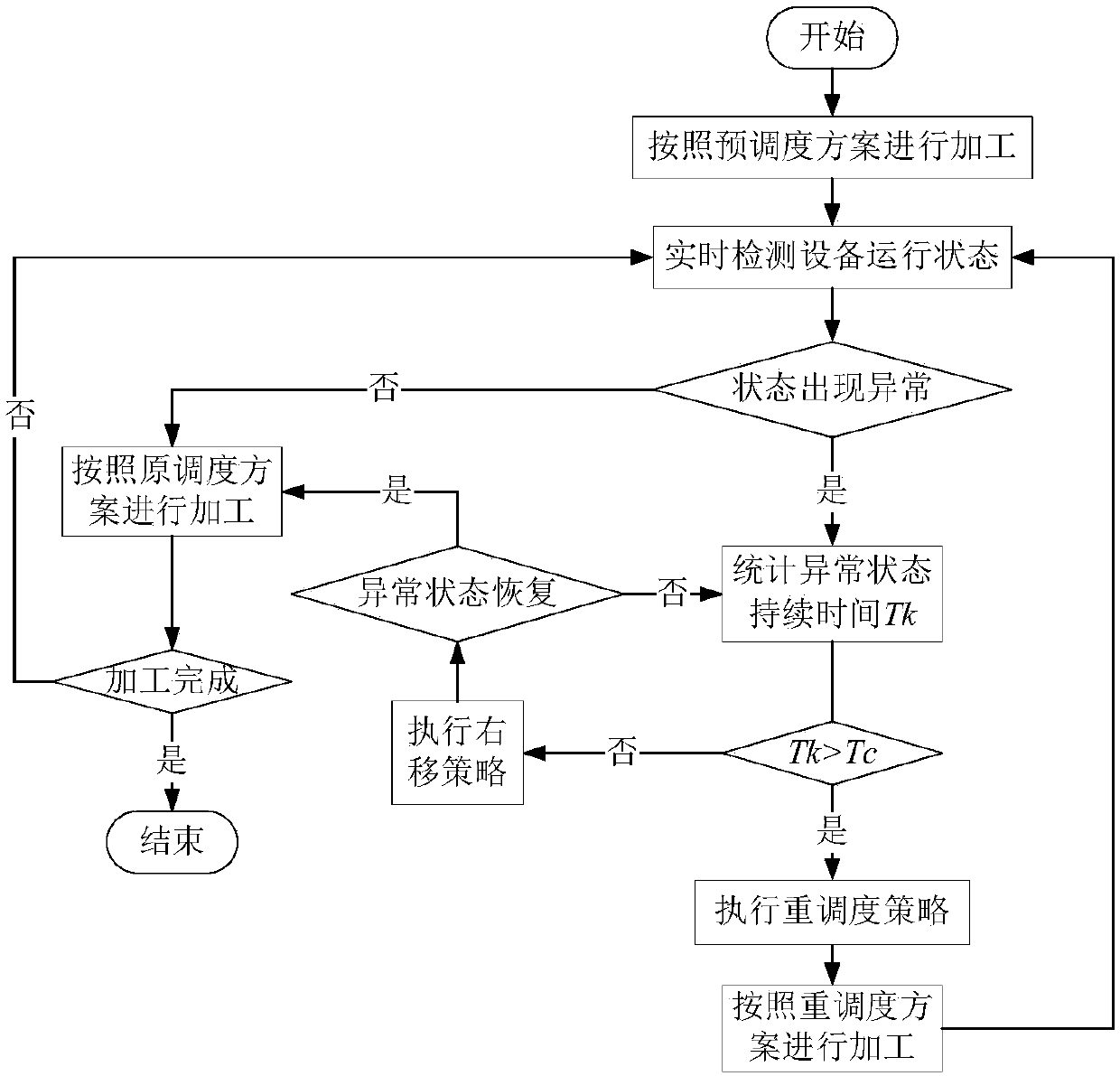

Method used

Image

Examples

Embodiment

[0061] In this example, the flexible job shop rescheduling method considering the availability of machining equipment is applied to a flexible job shop, which produces 4 workpieces, each workpiece has 4 processes to complete the processing process, and has 6 machine tools To process, the process that the equipment can process and the corresponding processing time are shown in Table 1, where Indicates that the optional machine number of the corresponding workpiece-related process is And the processing time on this machine is ω, multiple lines of this symbol indicate that a certain process can be processed on multiple different machines, and the processing time is different.

[0062] Table 1 Example of flexible job shop scheduling

[0063]

[0064]

[0065] According to the availability of machining equipment, equipment 1 needs preventive maintenance at time 33, the length of preventive maintenance is 10, equipment 5 needs preventive maintenance at time 22, and the leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com