A drilling resistivity advanced detection device and detection method for TBM

A technology of advanced detection and detection devices, which is applied in the direction of measuring devices, electric/magnetic exploration, radio wave measurement systems, etc., can solve the problem of lack of electrolyte environment between electrodes and drilling rock walls, inability to adapt to mechanization and automation, and increase construction time and construction costs to achieve the effect of improving depth and accuracy, good coupling, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

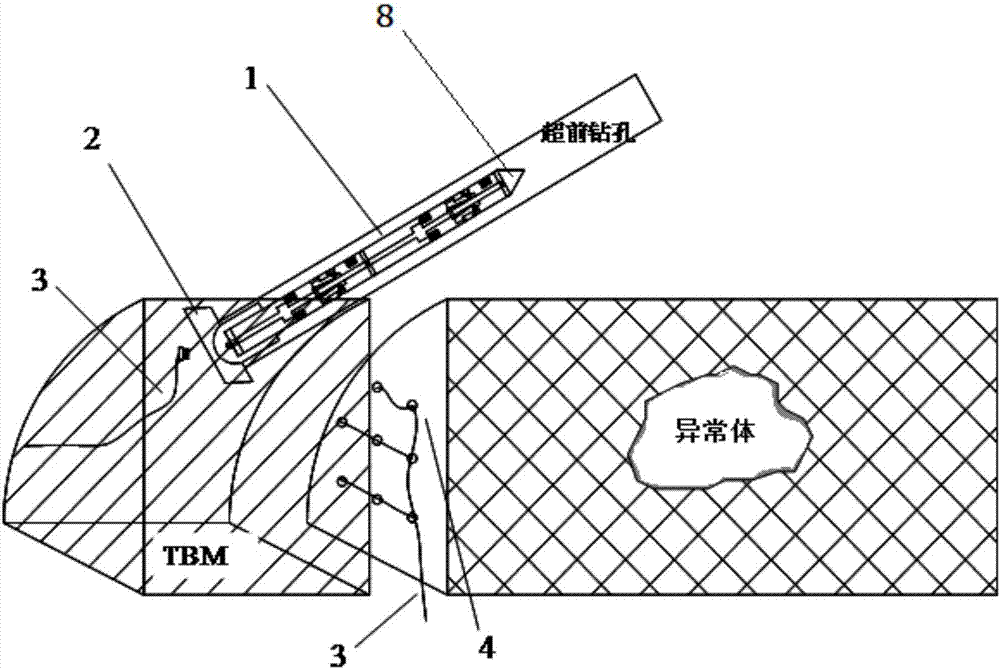

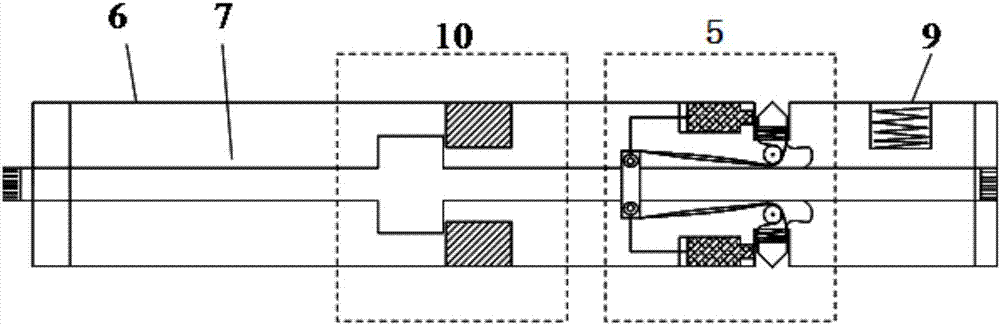

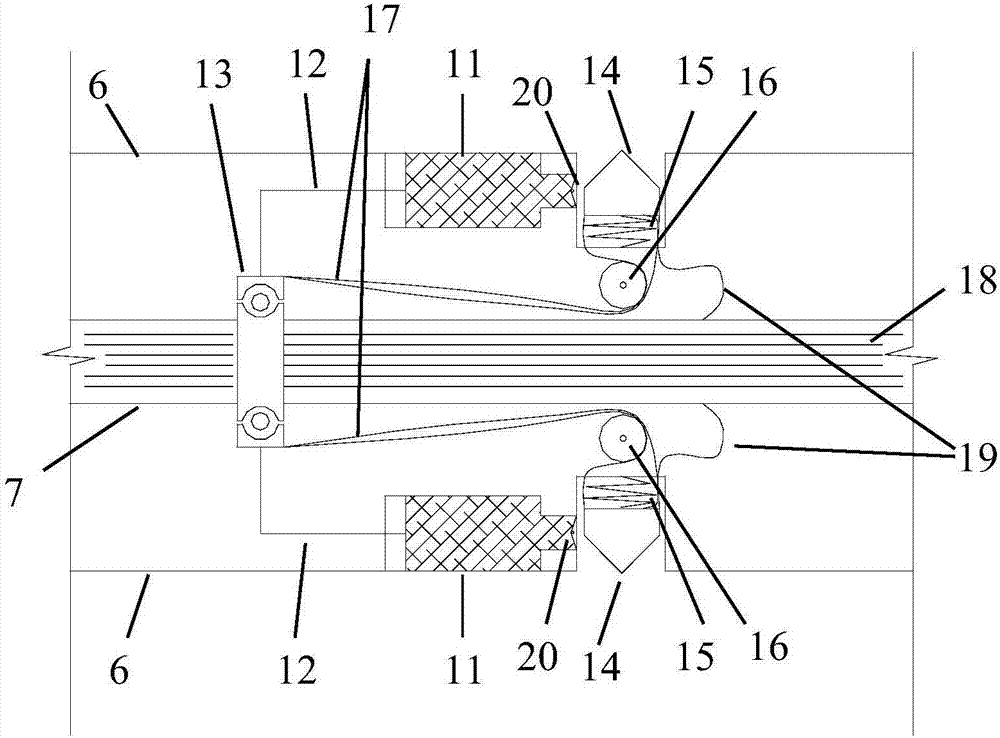

[0071] Such as figure 1 As shown, a tunnel drilling resistivity advanced detection device mainly includes an electrode delivery device 1 in the hole, an electrode coupling device 5 , a guiding depth determination device 2 , and a face array electrode 4 . The electrode delivery device 1 is an integral structure, mainly including an insulating high-strength outer sleeve 6 and an inner transmission rod 7 . The electrode coupling device 5 includes an electrolyte holding device 11 , a flexible coupling electrode 14 , an electrode pushing spring 15 , an electrode compression lead 17 , and a steering pulley 16 . In the process of entering the borehole and pushing out the borehole, the flexible coupling electrode 14 shrinks inside the outer sleeve 6; when performing resistivity measurement, the flexible coupling electrode 14 pops out of the outer sleeve 6, couples with the rock wall of the borehole, and simultaneously releases the electrolytic liquid. The guiding depth-determining d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com