Method for Acquiring Fault Information of Planetary Gearbox

A technology of planetary gearbox and acquisition method, which is applied in machine gear/transmission mechanism testing, machine/structural component testing, mechanical component testing, etc., can solve the problem of affecting system performance, arranging sensor measurement, meshing force information and vibration information Problems such as complex mapping relationships

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

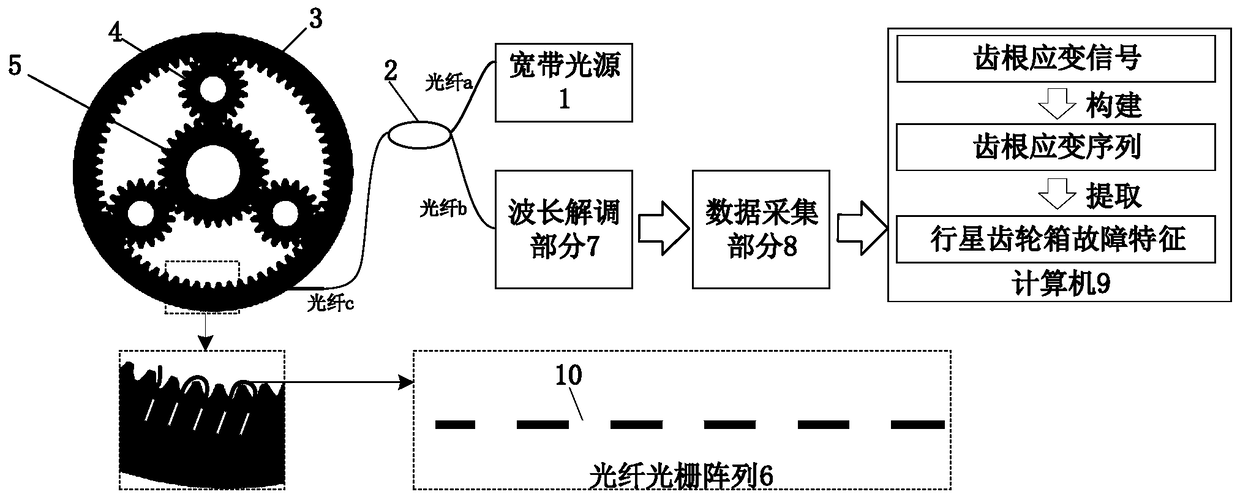

[0073] Such as figure 1 As shown, the present invention includes the ring gear 3, the planetary gear 4 and the sun gear 5 that form the planetary gear box. In the planetary gear box, the ring gear 3 is fixed, the sun gear 5 rotates around its central axis, and the planetary gear 4 In addition to rotation, it also revolves around the sun gear. Several continuous teeth of the inner ring gear 3 are used as detection teeth. The fiber grating array 6 is pasted on the tooth root of the inner ring gear 3. The light emitted by the broadband light source 1 passes through the optical fiber a and the 3dB coupler. 2 and fiber c are transmitted to the fiber grating array 6, where light reflection occurs in the fiber grating array 6, and the reflected light enters the wavelength demodulation part 7 through the fiber c, 3dB coupler 2 and fiber b, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com