Engineering drilling device

A drilling device and engineering technology, which is applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of low drilling efficiency and inability to guarantee the verticality of the hole, and achieve the effect of improving the ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

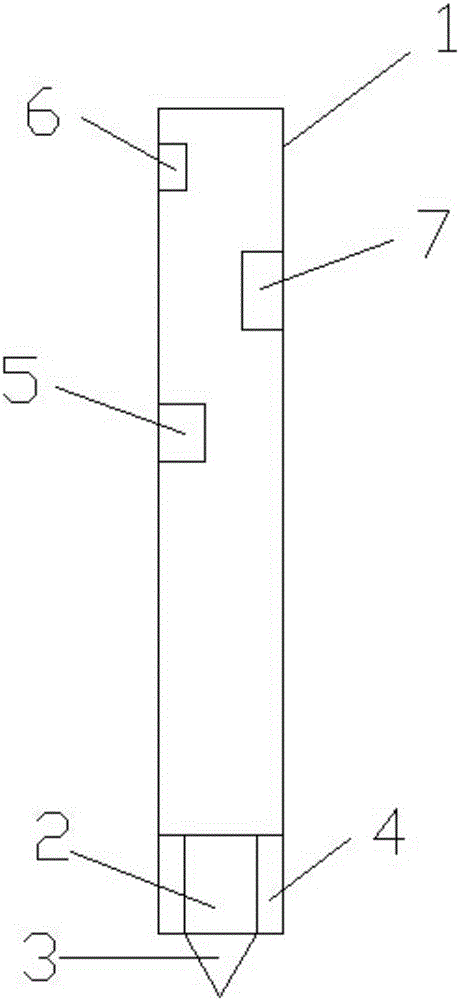

[0017] figure 1 The engineering drilling device shown includes a hollow drill rod 1, a connecting rod 2, and a drill bit 3, and the hollow drill rod 1, connecting rod 2, and drill bit 3 are connected sequentially from top to bottom, and the cross-sectional area of the upper end of the connecting rod 2 is equal to that of the drill bit 3 , the outer side of connecting rod 2 is provided with several drill plates 4, and described hollow drill rod 1 is provided with verticality sensor 5, controller 6, alarm 7, and described verticality sensor 5, alarm 7 are respectively connected with controller 6 connections.

[0018] The drill bit 3 is threadedly connected with the connecting rod 2 .

[0019] The end of the drill bit 3 is tapered with a taper of 30-45°.

[0020] The axes of the hollow drill rod 1, the connecting rod 2 and the drill bit 3 are on the same straight line.

[0021] The drill plates 4 are evenly distributed on the outside of the connecting rod 2 .

[0022] Durin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com