Self-healing concrete pile preventing frost heaving and bonding weakening

A concrete pile, self-healing technology, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of poor long-term operation of pile foundation, reduce the critical bearing capacity of piles, increase the diameter of steel bars, etc., and achieve good plasticity and stability. Toughness and adaptability to temperature, improvement of seismic performance, effect of appropriate thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit this invention.

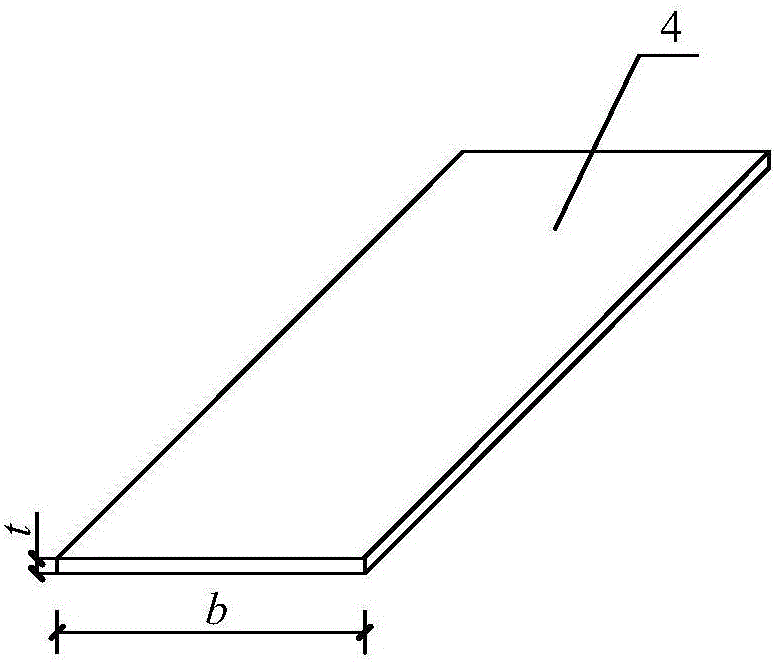

[0030] please see Figure 1-Figure 7 , a self-healing concrete pile with anti-freezing and pulling bond weakening provided by the present invention, in the process of concrete 2 mixing, put steel capsule 1, pour into the concrete pile model prepared in advance after being stirred evenly; Simultaneously for To improve the bonding performance between the steel bars 3 and the concrete 2, the steel capsules 1 connected in series through strip-shaped polypropylene fabrics 4 are wound on the steel bars 3.

[0031] When the tangential frost heave force acting on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com