Device for removing bubbles in pitch through vacuum auxiliary temperature differential method and bubble removing method thereof

A vacuum-assisted, temperature-difference method, applied in filament forming treatment, textile and papermaking, fiber treatment, etc., can solve the problems of inability to realize industrial application, unsuitability, and hindering the development of pitch-based carbon fiber continuous filament preparation technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

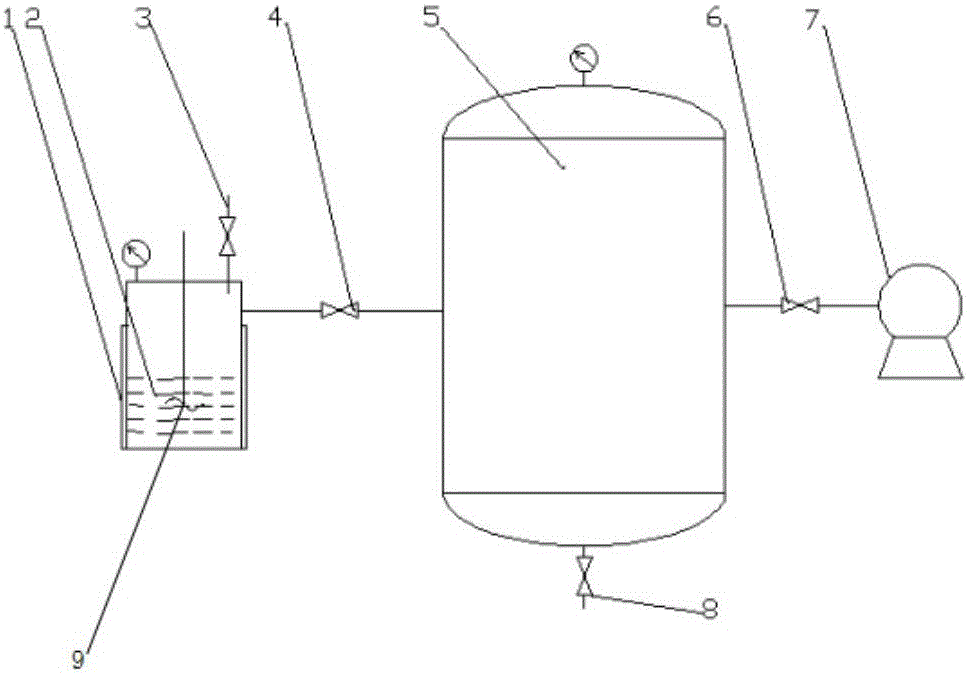

Image

Examples

Embodiment 1

[0026] This embodiment is a specific implementation of the present invention, specifically the following steps:

[0027] Step 1: Connect the degassing kettle 2 and the buffer tank 5, and evacuate to 100Pa, close the communication valve 1 4 and the communication valve 2 6 between the two, stop vacuuming, and pass inert gas into the degassing kettle 2 , by adjusting the 3 valves of the intake pipeline to keep the normal pressure in the degassing tank, heat the asphalt in the tank to 320°C, and stir the asphalt with a stirrer for 2 hours;

[0028] Step 2: Stop stirring, close the valve 3 of the intake pipeline, open the connecting valve 1, and gradually cool down to 50°C below the softening point of the asphalt. At this time, the bubbles crack, and continue to vacuumize the degassing kettle 2, the pressure is 50Pa, and the time is 2h;

[0029] Step 3: Raise the temperature of the defoaming tank 2 to 340°C, and continue to carry out negative pressure sedimentation treatment on th...

Embodiment 2

[0033] This embodiment is a specific implementation of the present invention, specifically the following steps:

[0034] Raise the heating temperature of the asphalt in step 1 in Example 1 to 350°C, and extend the stirring time to 4h; reduce the temperature in step 2 to 100°C below the softening point of the asphalt, and appropriately extend the negative pressure treatment time to 4h; The temperature in the medium was raised to 365°C, and the pressure was dropped to 5kPa, and the settling time was extended to 15h.

[0035] The air bubble removal rate can reach 99.9%, and the continuous length of the spinnable asphalt can reach more than 4km.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com