Deaeration method of cellulose ionic liquid solution for solvent spinning

A technology of ionic liquid and cellulose, which is applied in fiber treatment, filament forming treatment, textile and paper making, etc., can solve the problems of degassing efficiency, energy saving effect and operability inferior to degassing method, and reduce the difficulty of degassing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

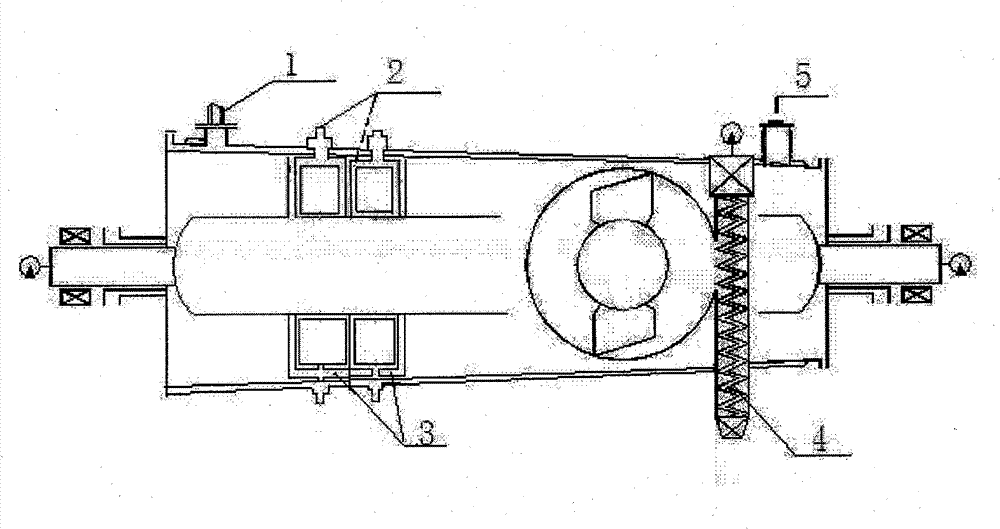

Image

Examples

Embodiment 1

[0027] Degassing of 10% mass concentration cellulose / 1-allyl-3-methylimidazolium chloride ionic liquid solution

[0028] Put the dry pulp fines into the dissolution tank, stir and vacuumize for 20 minutes, and then inhale the degassed ionic liquid 1-allyl-3-methylimidazolium chloride through the vacuum negative pressure in the dissolution tank. compound, while inhaling and stirring to vacuumize. After the addition, stir and vacuum for 90 minutes, the vacuum degree is -0.099~-0.090MPa, and the temperature of the spinning solution in the dissolution tank is 95°C. After vacuum dissolution, the viscosity of the material is 3200Pa.S. When the temperature of the material is raised from 95°C to 140°C, the viscosity of the spinning solution drops to 900Pa.S. In this way, as the viscosity of the spinning solution is greatly reduced, the fluidity becomes better, which is beneficial to the effective removal of air bubbles in the material. The material is uniformly fed into a horizonta...

Embodiment 2

[0030] Degassing of cellulose / 1-butyl-3-methylimidazolium chloride solution with 8% mass concentration

[0031] Put the dry pulp fines into the dissolving tank, stir and vacuumize for 10 minutes, then inhale the 1-butyl-3-methylimidazolium chloride liquid after vacuum distillation and degassing through the vacuum negative pressure in the dissolving tank, Stir and vacuum while inhaling. After the addition, stir and vacuum for 30 minutes, the vacuum degree is -0.099~-0.090MPa, and the temperature of the spinning solution in the dissolution tank is 60°C. After vacuum dissolution, the viscosity of the material is 2000Pa.S. When the temperature of the material is raised from 60°C to 110°C, the viscosity of the spinning solution drops to 600Pa.S. In this way, as the viscosity of the spinning solution is greatly reduced, the fluidity becomes better, which is beneficial to the effective removal of air bubbles in the material. The material is evenly fed into the horizontal continuou...

Embodiment 3

[0033] Degassing of cellulose / 3-methyl-N-butylchloropyridine solution with 12% mass concentration

[0034] Put the dry pulp fines into the dissolving tank, stir and vacuumize for 20 minutes, then inhale the degassed ionic liquid 3-methyl-N-butylchloropyridine through vacuum negative pressure. Stir and vacuum. After the addition, stir and vacuum for 150 minutes, the vacuum degree is controlled in the range of -0.099~-0.090MPa, and the solution temperature in the tank is 80°C. After vacuum dissolution, the viscosity of the material is 3200Pa.S. Raise the temperature of the material from 80°C to 120°C, at this time the viscosity of the spinning solution will drop to 1000Pa.S. The material is evenly fed into a horizontal continuous stripping kettle with a length-to-diameter ratio of 5:1, a vacuum degree stabilized at -0.099 to -0.095MPa, and a temperature of 120°C through a metering pump. The feed rate is 265ml / min. The material is continuously forced to form a film with a thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com