A degassing device

A defoaming, curved body technology, applied in the directions of liquid degassing, separation methods, chemical instruments and methods, etc., can solve the problems of low efficiency, poor defoaming effect of the defoaming device, etc., to lengthen the flow path and improve the defoaming effect. Efficiency, the effect of increasing the exposed area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

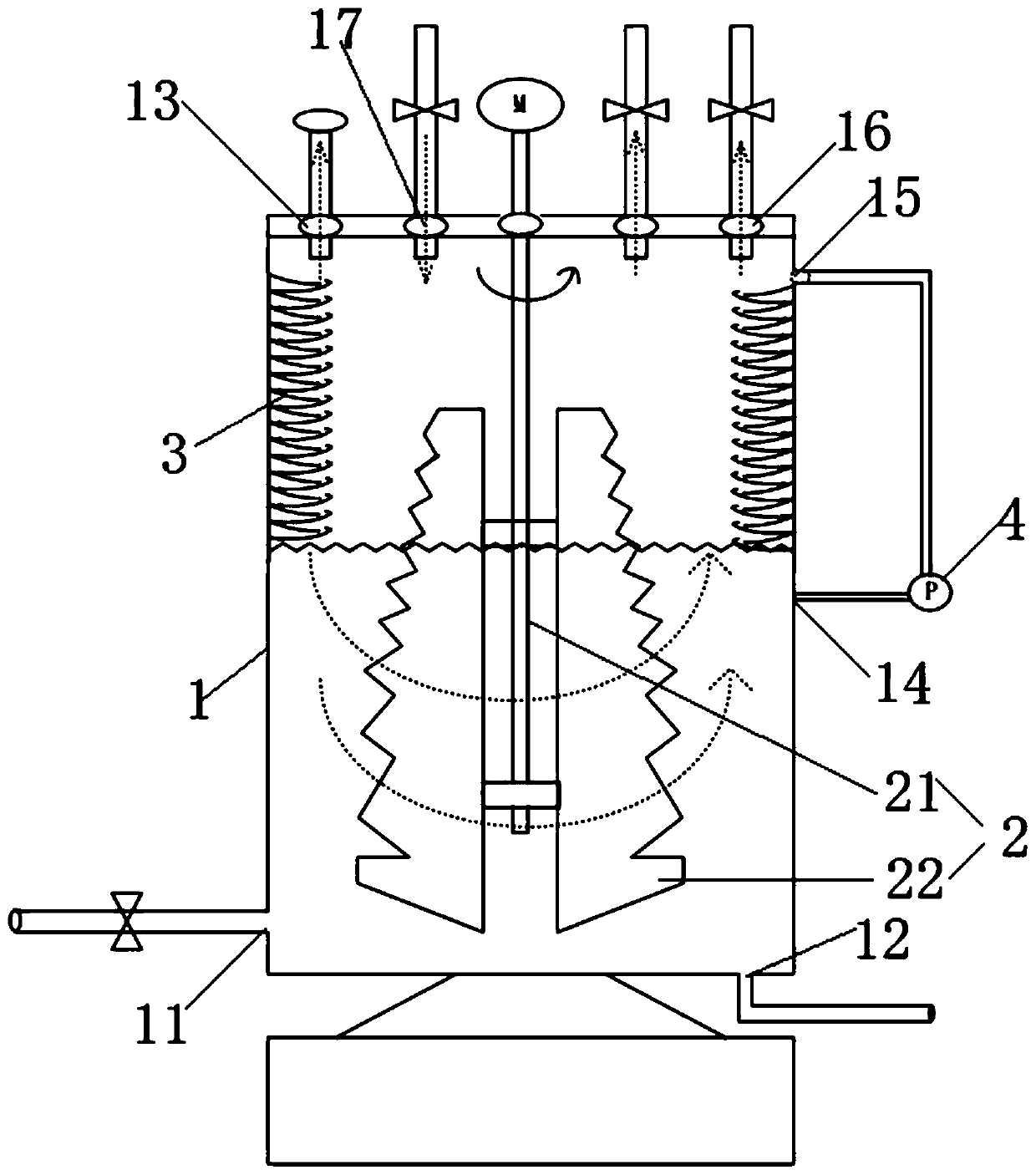

[0044] This embodiment provides a degassing device, such as figure 1 As shown, it includes a cylinder body 1 , a stirring assembly 2 and a multi-layer spread structure 3 ; among two vertically adjacent spread structures 3 , the upper spread structure 3 is sleeved on the lower spread structure 3 .

[0045] Wherein, the barrel 1 has an inner cavity, a liquid inlet 11 and a liquid outlet 12 communicating with the inner cavity are opened on the side wall, and an exhaust port 13 is opened on the top wall.

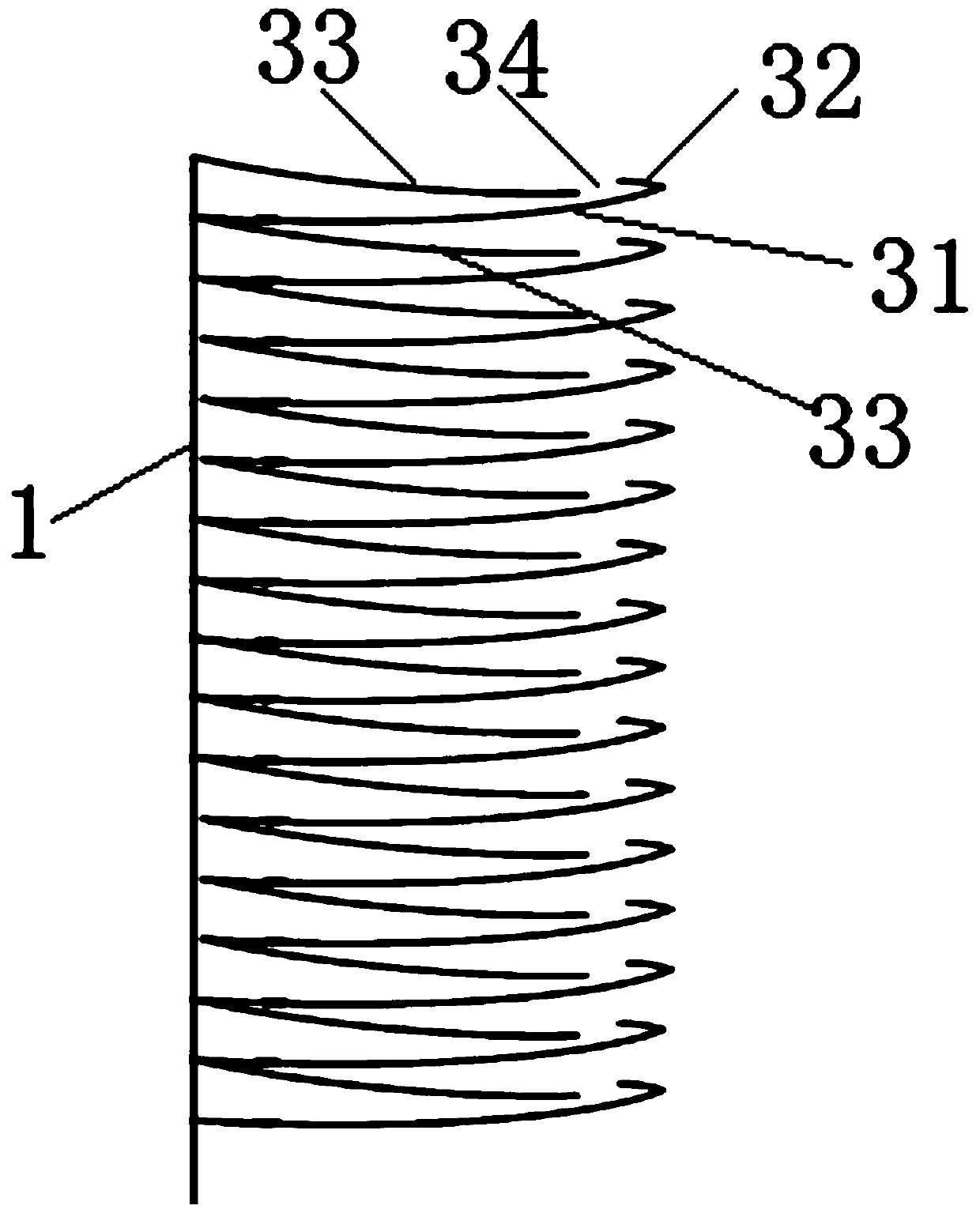

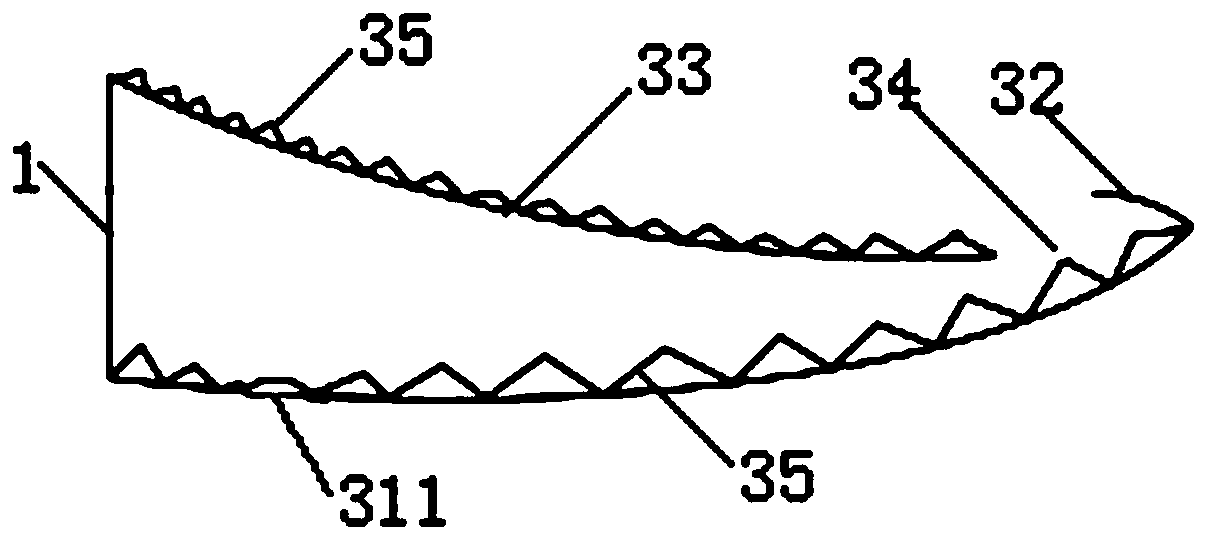

[0046] like figure 2 As shown, any layer of the spread structure 3 includes a meandering curved surface body 32 , a main curved surface body 31 and a diversion curved surface body 33 arranged in sequence from top to bottom, and the spread structure 3 has a ring structure as a whole. An inner hole is provided in the middle of the spreading structure 3 , and the spreading structure 3 is sheathed outside the stirring assembly 2 through the inner hole, and a required distance is r...

Embodiment 2

[0065] This embodiment provides a degassing device. Compared with the degassing device provided in Example 1, the difference is that the degassing device is not provided with a vacuum device, and correspondingly, the first wall is not provided on the top wall of the cylinder body 1. Three openings 16, the gas formed during the degassing process of the solution is naturally discharged through the exhaust port 13.

Embodiment 3

[0067] This embodiment provides a degassing device, which is different from the degassing device provided in Embodiment 1 or Embodiment 2 in that the nitrogen delivery equipment can also be replaced by other inert gas delivery equipment, such as neon gas .

[0068] As an alternative embodiment, the gas conveying device can also be replaced by a water pump, and the solution is drawn out from the liquid outlet 12 through the liquid outlet 12 .

[0069] As a further alternative embodiment, the degassing device may not be provided with the gas delivery device. After the solution is defoamed, the solution is discharged from the liquid outlet 12 under its own gravity. In this embodiment, the liquid outlet 12 is opened on the bottom wall of the cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com