Fluid degassing device and method in a semiconductor processing system

A technology for processing systems and semiconductors, applied in chemical instruments and methods, semiconductor/solid-state device manufacturing, liquid degassing, etc., can solve problems such as low efficiency, affecting productivity, and poor results, achieving a high degree of automation, simple structure, The effect of stable pressure flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

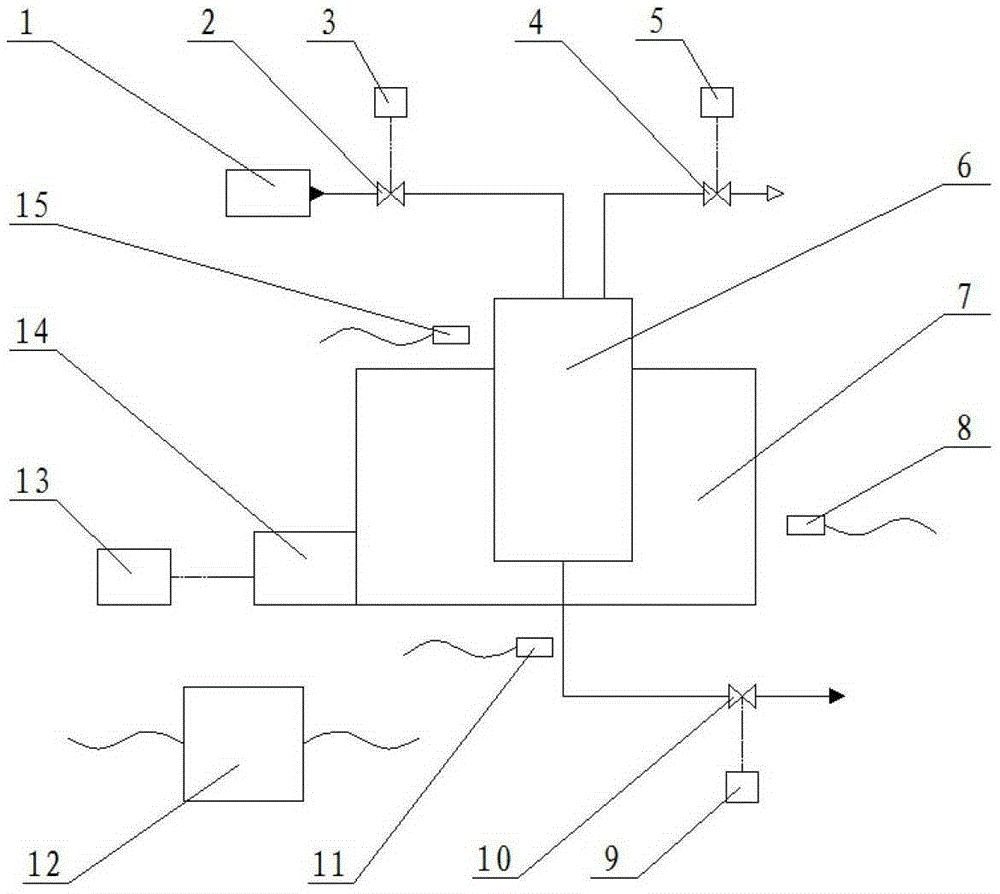

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] like figure 1 As shown, the present invention only relates to the fluid pipeline part in the semiconductor processing system, that is, only the fluid is degassed. Etching liquid, but not limited to this, any fluid used in semiconductor processing system, the pressure range is between 0.1MPa and 0.4MPa can be degassed by this device.

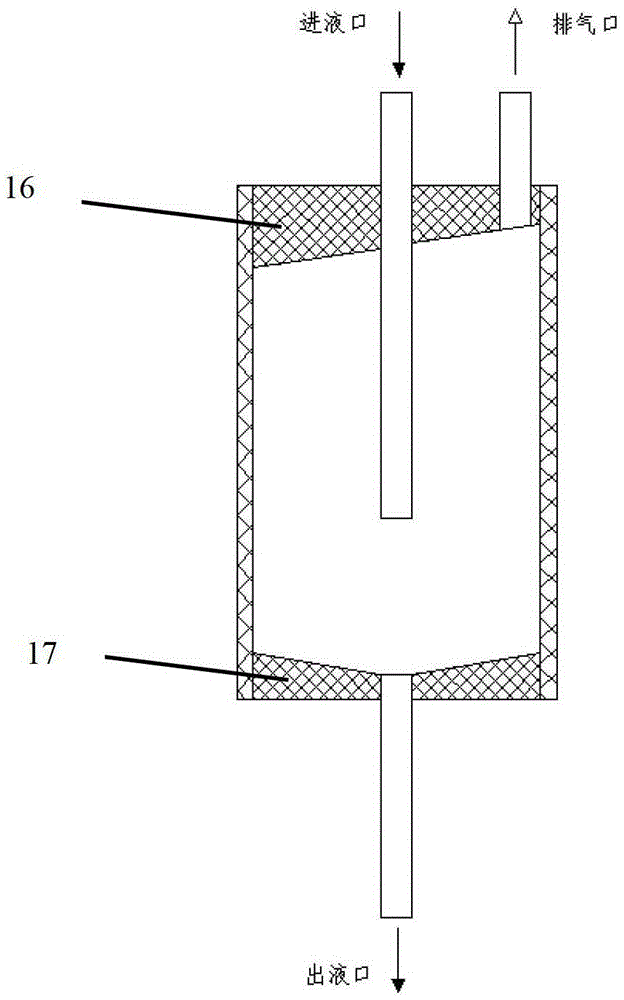

[0028] A fluid degassing device in a semiconductor processing system, comprising a buffer container 6, a medium container 7, an ultrasonic transducer 14, and a transducer control unit 13, wherein the buffer container 6 is immersed in the medium of the medium container 7, and the buffer container There is a gap between the bottom surface of 6 and the bottom surface of the medium container 7; the buffer container 6 is connected to the liquid supply device 1 through the automatic valve I2, the buffer container 6 is connected to the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com