Device for continuous preparation of poly(p-phenylene terephthalamide) polymer and preparation method

A technology of poly-p-phenylene terephthalamide and polymers, which is applied in the field of polymer material manufacturing and industrial continuous preparation of poly-p-phenylene terephthalamide polymers. Continuous polymerization precision metering and mixing, reduced reactivity and other issues, to achieve the effect of continuous and stable spinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

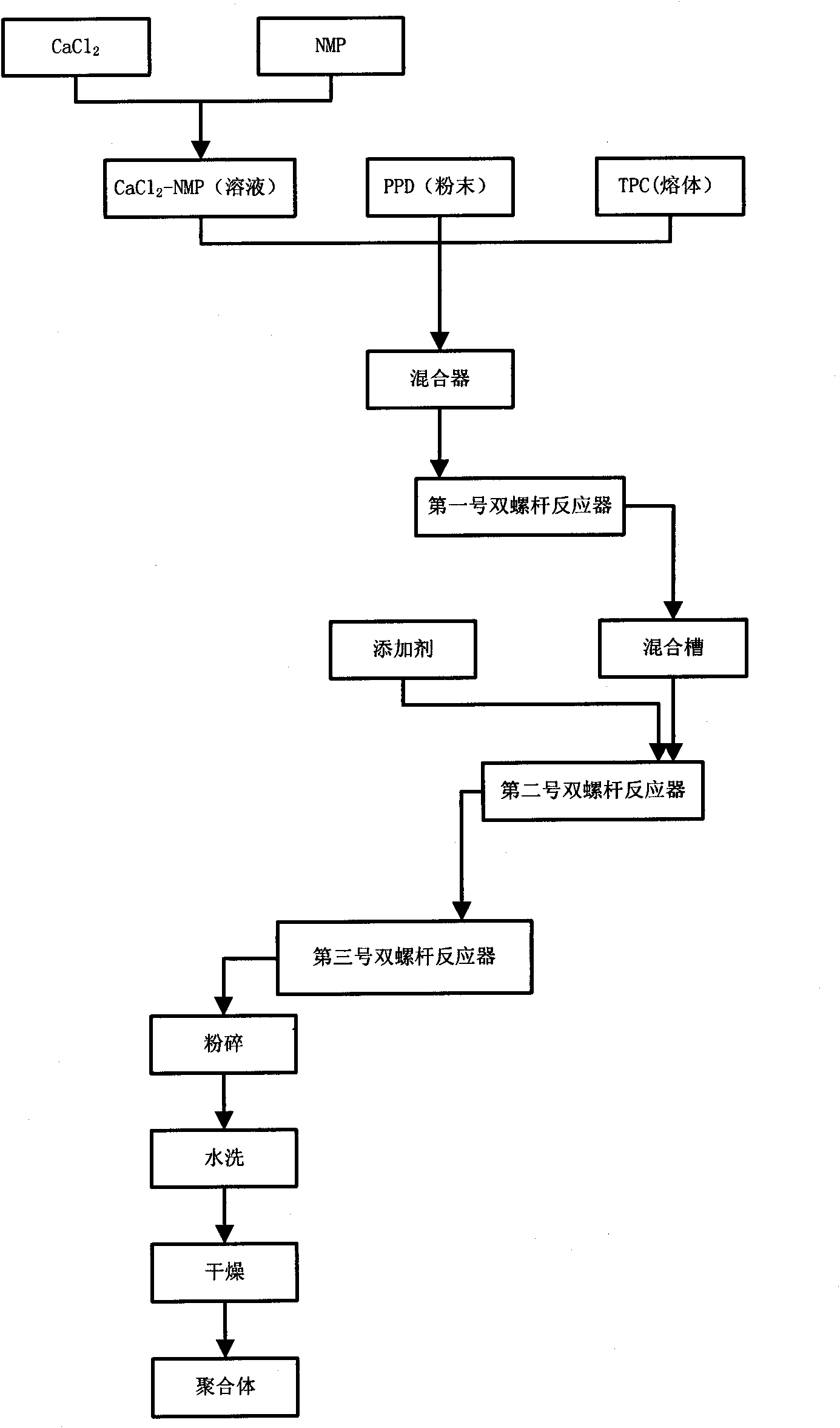

[0031] A preparation method for continuously preparing poly(p-phenylene terephthalamide) polymer, comprising the following steps:

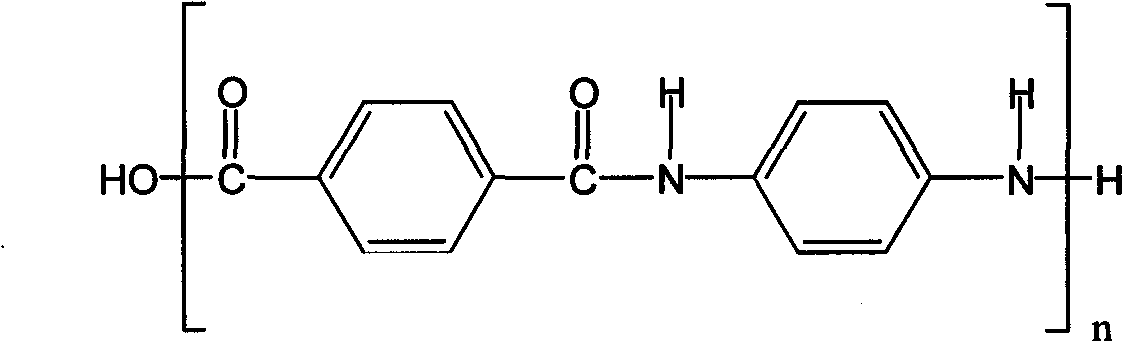

[0032] (1) A co-solvent with a mass percentage concentration of 4-12% is dissolved in one of N-methylpyrrolidone, dimethylacetamide, N-ethylpyrrolidone, diethylacetamide or a mixture thereof In the solvent, form co-solvent-solvent system; Described co-solvent is chloride, and they are a kind of or its mixture in calcium chloride, magnesium chloride, lithium chloride;

[0033] (2) co-solvent-solvent and p-phenylenediamine and terephthaloyl chloride are continuously added to the mixer simultaneously, and flow into No. 1 twin-screw reactor after mixing; described p-phenylenediamine and terephthaloyl dichloride Acid chloride, its molar ratio is 1:1~1.01;

[0034] (3) The material flows into the mixing tank after being reacted in the No. 1 twin-screw reactor;

[0035] (4) oligomers and additives in the mixing tank are uniformly pumped into the No. 2 tw...

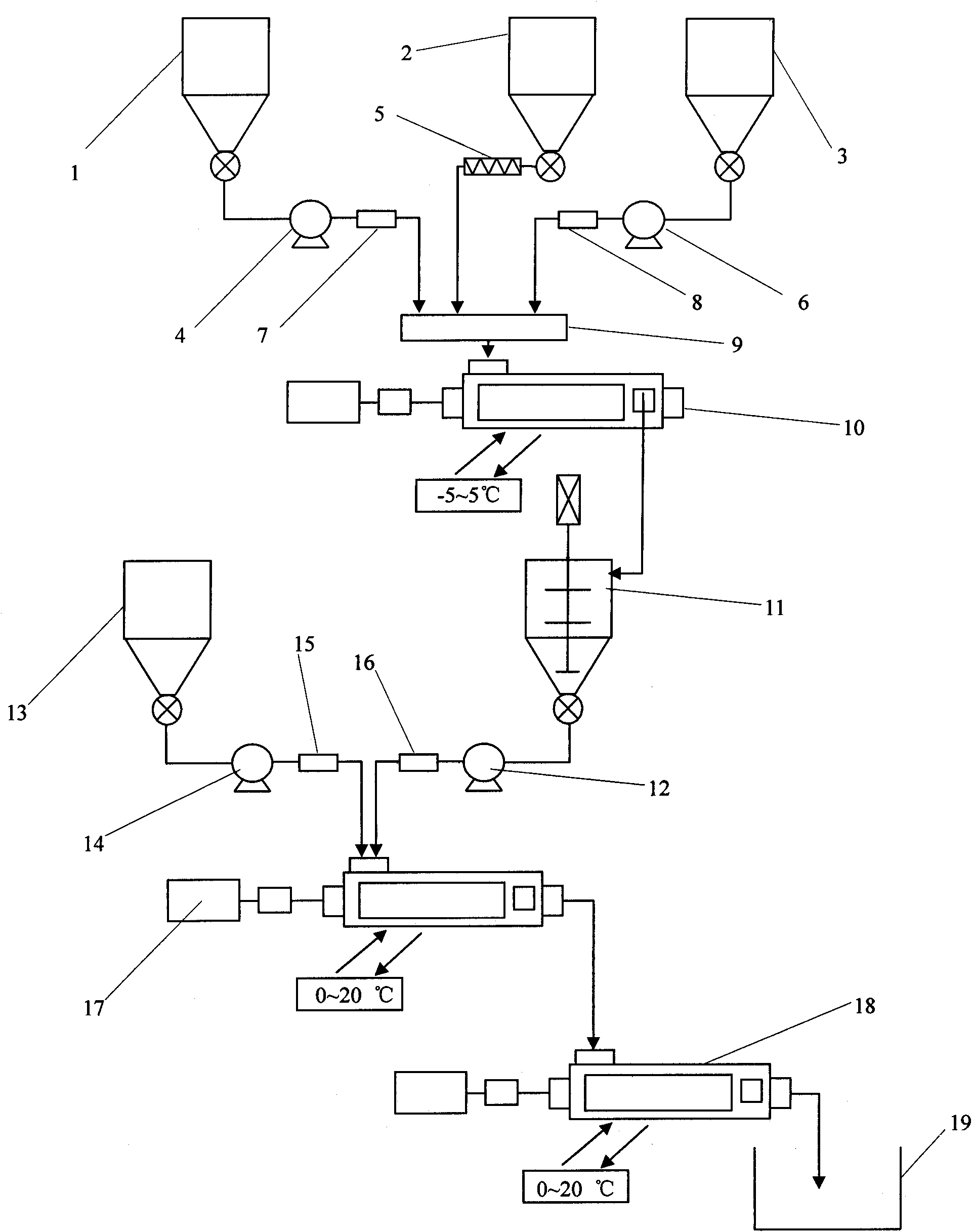

Embodiment 1

[0039] 7998.41kgN-methylpyrrolidone (NMP) solvent was added to 10m 3 In the dissolution kettle, after the solvent was heated up to 70°C, 695.51kg of anhydrous calcium chloride (CaCl 2 ) powder, stirred and dissolved for 4 hours, discharged into 30m 3 in a mixing tank. CaCl 2 -NMP solvent at 1086.74kg / h, p-phenylenediamine (PPD) powder at 56.74kg / h, and terephthaloyl chloride (TPC) melt at 106.52kg / h are continuously added to the mixer for mixing, and the inflow diameter is 125mm , The No. 1 twin-screw reactor with an aspect ratio of 7.2, a rotational speed of 200rpm, and a jacket temperature of 0°C, reacted in the reactor for 10s and then flowed into the mixing tank to form oligomers. The flow rate of oligomers was 1250kg / h Pump into the No. 2 twin-screw reactor with a diameter of 125mm, an aspect ratio of 7.2, a rotating speed of 200rpm, and a jacket temperature of 0°C. After reacting in the reactor for 10s, the inflow diameter is 400mm, and the aspect ratio is 10. No. 3 ...

Embodiment 2

[0041] 7998.41kgN-methylpyrrolidone (NMP) solvent was added to 10m 3 In the dissolution kettle, after the solvent was heated up to 70°C, 695.51kg of anhydrous calcium chloride (CaCl 2 ) powder, stirred and dissolved for 4 hours, discharged into 30m 3 in a mixing tank. CaCl 2 -NMP solvent at 1086.74kg / h, p-phenylenediamine (PPD) powder at 56.74kg / h, and terephthaloyl chloride (TPC) melt at 106.52kg / h are continuously added to the mixer for mixing, and the inflow diameter is 125mm The No. 1 twin-screw reactor with an aspect ratio of 7.2, a rotational speed of 200rpm, and a jacket temperature of 0°C, reacted in the reactor for 10s and then flowed into the mixing tank to form oligomers. The oligomers were flown at 1250kg / h, Liquid ammonia is simultaneously and continuously pumped at 16.05kg / h into the No. 2 twin-screw reactor with a diameter of 125mm, an aspect ratio of 7.2, a rotational speed of 200rpm, and a jacket temperature of 0°C. No. 3 twin-screw reactor with a diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com