Method for preparing AZ31-RE wrought magnesium alloy

A technology of AZ31-RE and wrought magnesium alloy, which is applied in the field of alloys, can solve problems such as low safety factor, serious environmental pollution, and magnesium residue, and achieve the effects of reducing production cost, reducing residue rate, and refining grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

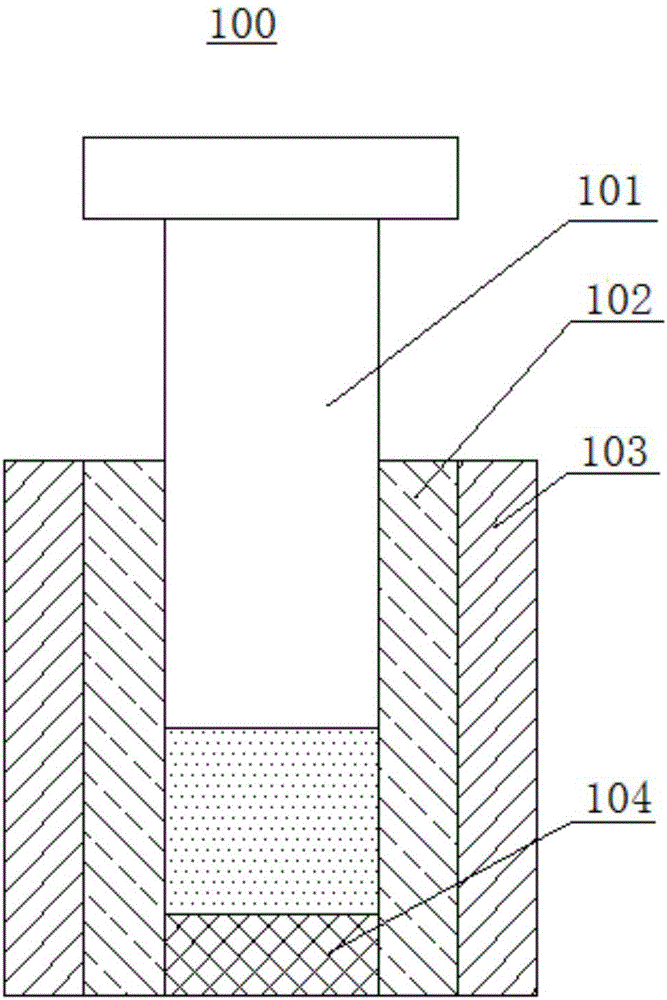

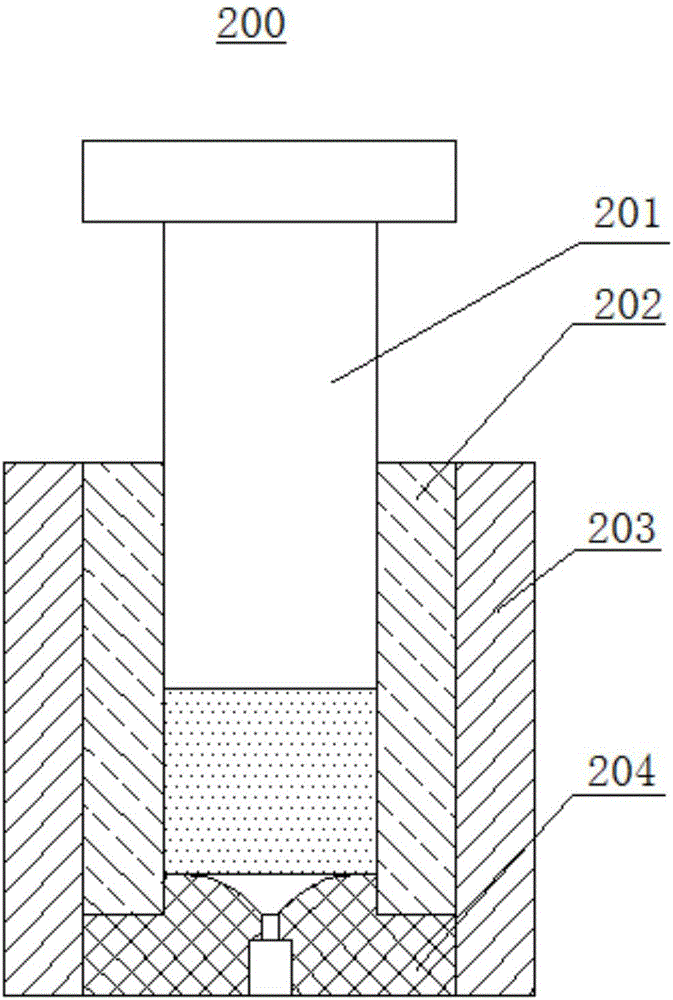

[0051] The cold pressing die 100 and the extrusion die 200 are used in the process of preparing the AZ31-RE deformed magnesium alloy provided in this embodiment, see figure 1 with figure 2 . Wherein, the cold pressing die 100 comprises a cold pressing punch 101, a cold pressing inner sleeve 102, a cold pressing sleeve 103 and a pressure pad 104; the extrusion die 200 comprises an extrusion punch 201, an extrusion inner sleeve 202, an extrusion Sleeve 203 and die 204. The diameter of the cold pressing punch 101 is 4 mm smaller than that of the extruding punch 201 , and the inner diameter of the cold pressing inner sleeve 102 is 4 mm smaller than that of the extruding inner sleeve 202 .

[0052] The method for preparing the AZ31-RE wrought magnesium alloy provided in this embodiment comprises the following steps:

[0053] a. Machining the AZ31 magnesium alloy and the Mg-RE master alloy: using a lathe to process the AZ31 magnesium alloy into the first chips with a size of 5mm...

Embodiment 2

[0063] In the method for preparing the AZ31-RE wrought magnesium alloy provided in this example, the size of the AZ31 magnesium alloy processed in step a is different from that in Example 1, and the rest of the steps are the same as in Example 1. In this embodiment, the size of the processed AZ31 magnesium alloy is 3mm×2.2mm×0.5mm.

Embodiment 3

[0065] In the method for preparing AZ31-RE wrought magnesium alloy provided in this example, the mass ratio of the first scrap to the second scrap is different from that in Example 1, and the rest of the steps are the same as in Example 1. In this embodiment, the mass ratio of the first scrap material to the second scrap material is 99.5:0.5, and in the obtained AZ31-RE deformed magnesium alloy, the mass percentage of rare earth elements is 0.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com