Pit mud formula for brewing, pit mud and making process thereof

A production process and pit mud technology, which is applied in the field of winemaking, can solve the problems of poor taste, poor effect, and low quality of liquor, and achieve the effect of positive aroma, broad application prospects and long-lasting aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

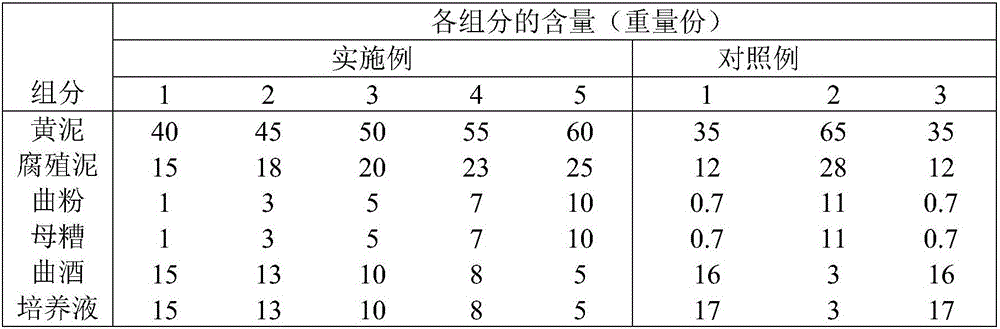

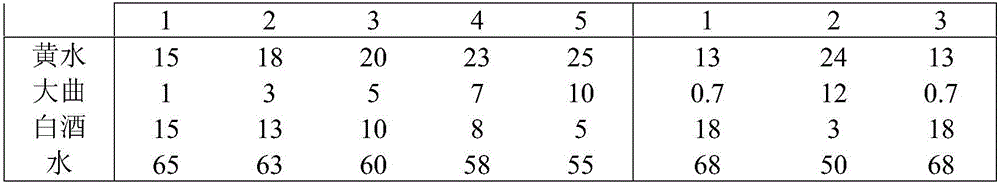

Examples

Embodiment 1

[0043] The following pit mud production process is used to make pit mud:

[0044] (1) material preparation step: get each component specified in embodiment 1 in table 1 and table 2 by weight parts. Among them, the humus mud is taken from the lake, the alcohol purity of the liquor is 58%, and the koji wine is Daqu wine.

[0045] (2) The step of preparing the culture medium: mixing the yellow water, Daqu, white wine and water, and fermenting in an airtight manner for 18 days to obtain the culture medium.

[0046] (3) Pretreatment step: crushing the yellow mud, the soil non-capillary porosity of the crushed yellow mud is 2%, and the soil clay content of the crushed yellow mud is 60%. Then mix the yellow mud and humic mud, stir evenly and let it stand for 0.5h to form the base mud.

[0047] (4) Fermentation step: mix koji powder and mother's grains and add it to the base mud, then add the culture medium and koji wine, stir evenly, put it in the cellar, and ferment it at 35°C for 2...

Embodiment 2

[0049] The following pit mud production process is used to make pit mud:

[0050] (1) material preparation step: get each component specified in embodiment 2 in table 1 and table 2 by weight parts. Among them, the humus mud is taken from Hetang, the alcohol purity of the liquor is 63%, and the koji wine is Daqu wine.

[0051] (2) The step of preparing the culture medium: mixing the yellow water, Daqu, white wine and water, and fermenting in a sealed container for 23 days to obtain the culture medium.

[0052] (3) Pretreatment step: crushing the yellow mud, the soil non-capillary porosity of the crushed yellow mud is 6%, and the soil clay content of the crushed yellow mud is 30%. Then mix the yellow mud and humic mud, stir well and let it stand for 2 hours to form the base mud.

[0053] (4) Fermentation step: mix koji powder and mother's grains and add them to the base mud, then add culture medium and koji wine, stir evenly, put them in the cellar, and seal and ferment at 25°...

Embodiment 3

[0055] The following pit mud production process is used to make pit mud:

[0056] (1) material preparation step: get each component specified in embodiment 3 in table 1 and table 2 by weight parts. Among them, the humus mud is taken from Hetang, the alcohol purity of the liquor is 60%, and the koji liquor is Daqu liquor.

[0057] (2) The step of preparing the culture medium: mixing yellow water, Daqu, white wine and water, and fermenting in an airtight manner for 20 days to obtain the culture medium.

[0058] (3) Pretreatment step: crushing the yellow mud, the soil non-capillary porosity of the crushed yellow mud is 4%, and the soil clay content of the crushed yellow mud is 45%. Then mix the yellow mud and humic mud, stir evenly and let it stand for 1.5 hours to form the base mud.

[0059] (4) Fermentation step: mix koji powder and mother's grains and add them to the base mud, then add culture medium and koji wine, stir evenly, and put them into the cellar pool. Old cellar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com