Heatproof and wear resistant lining material

A technology of heat-insulating wear-resistant lining and base material, applied in the petrochemical field, can solve the problems of reducing the economic benefits of enterprises, reducing the operation rate of equipment, consuming large energy and manpower, etc., to shorten the oven time, improve the comprehensive performance, early Strength-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

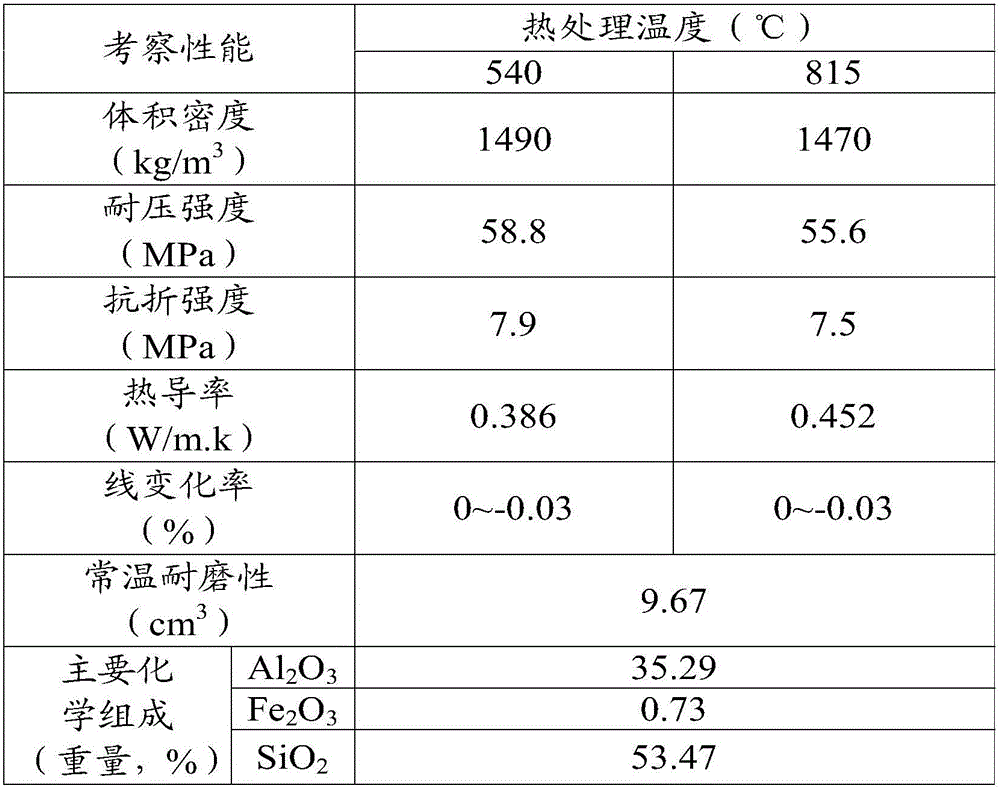

Embodiment 1

[0060] This implementation provides a heat-insulating and wear-resistant lining material, which can be used for pouring construction. The lining material consists of the following components:

[0061] Aggregate: Glazed large particles 50%, floating beads 10%, α-quartz 6%. The particle size distribution of the glazed large particles is 20% (weight) of 5-8mm particles, 5% (weight) of 2.5-5mm particles, 10% (weight) of 1.2-2.5mm particles, and 15% (weight) of 0.3-1.2mm particles. The particle size of floating beads is 0.15mm, and the particle size of α-quartz is 0.15mm.

[0062] Powder: 5% α-crystalline alumina powder, particle size ≤ 0.045mm; 4% silica fume, particle size ≤ 0.045mm.

[0063] Binder: 25% aluminate cement CA70.

[0064] The weight percentages of the above components are all based on the total weight of aggregate, binder and powder.

[0065] Compound admixture: mineral coagulant: 0.05%, β-naphthalene sulfonate (Na 2 SO 4 ≤5%): 0.25%, sodium tripolyphosphate 0...

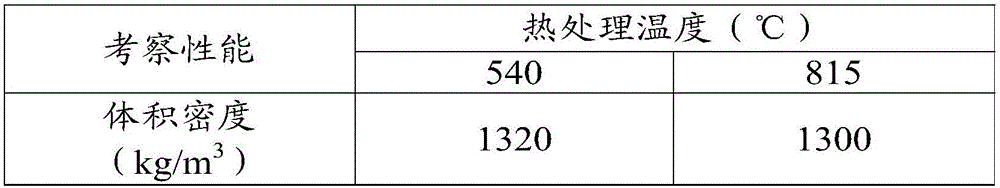

Embodiment 2

[0075] This implementation provides a heat-insulating and wear-resistant lining material, which can be used for spraying construction. The lining material consists of the following components:

[0076] Aggregate: 45% glazed particles, 5% floating beads, 5% α-quartz. The particle size distribution of the glazed particles is 20% (weight) of 2.5-5mm particles, 10% (weight) of 1.2-2.5mm particles, and 15% (weight) of 0.3-1.2mm particles. The particle size of floating beads is 0.15mm, and that of α-quartz is 0.15mm.

[0077] Powder: 5% α crystal form alumina micropowder, particle size ≤0.045mm; microsilica fume 4%, particle size ≤0.045mm; combined clay 6%, particle size ≤0.045mm.

[0078] Binder: 30% aluminate cement CA50.

[0079] The weight percentages of the above components are all based on the total weight of aggregate, binder and powder.

[0080] Compound admixture: mineral coagulant: 0.05%, β-naphthalene sulfonate (Na2SO 4 ≤5%): 0.3%. The weight percent of each compone...

Embodiment 3

[0091] This implementation provides a heat-insulating and wear-resistant lining material, which can be used for smearing construction. The lining material consists of the following components:

[0092] Aggregate: Glazed large particles 45%, floating beads 10%, α-quartz 5%. The particle size distribution of the glazed large particles is 20% (weight) of 2.5-5mm particles, 10% (weight) of 1.2-2.5mm particles, and 15% (weight) of 0.3-1.2mm particles. The particle size of floating beads is 0.15mm, and that of α-quartz is 0.15mm.

[0093] Powder: 5% α crystal form alumina micropowder, particle size ≤0.045mm; microsilica fume 4%, particle size ≤0.045mm; combined clay 6%, particle size ≤0.045mm.

[0094] Binder: 30% aluminate cement CA50.

[0095] The weight percentages of the above components are all based on the total weight of aggregate, binder and powder.

[0096] Compound admixture: mineral coagulant: 0.05%, β-naphthalene sulfonate (Na 2 SO 4 ≤5%): 0.3%, sodium tripolyphosp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com