Descaling separation assembly and landfill leachate MVR evaporation device comprising same

A technology for separating components and evaporating devices, applied in the directions of heating water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc., which can solve the problems of increasing raw material and energy consumption, reducing equipment service life, increasing thermal resistance and Flow resistance and other issues can be improved to improve resource utilization, prolong service life, and keep clean as new.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

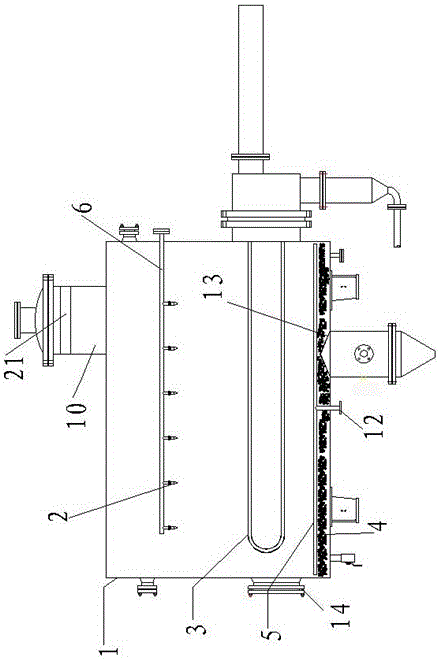

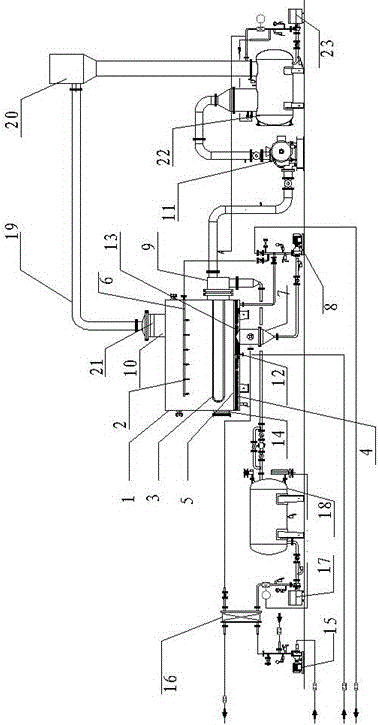

[0032] Embodiment 1, according to a certain proportion, the inert solid particles 4 of special specifications and sizes are first added to the bottom of the separator airtight tank 1 at one time through the inert solid particle inlet 14, and the high-concentration landfill leachate (or electroplating wastewater, heavy metal wastewater) at normal temperature ) after metering, enter the condensed water preheater 16 to increase the temperature of the feed liquid (preheated to the evaporation temperature) through the feed pump 15, enter the flotation device 7, pass through the discharge circulation pump 8, enter the feed pipe 6 and then enter the feed liquid Nozzle 2, the heated high-concentration landfill leachate is evenly distributed on the heating pipe 3 under the action of the feed liquid nozzle 2, and the steam compressor 11 is turned on at the same time, the heated high-concentration landfill leachate (or electroplating wastewater, heavy metal wastewater ) evaporate and vapo...

Embodiment 2

[0035] Embodiment 2, first according to a certain proportion, the inert solid particles 4 of special specifications and sizes are added to the bottom of the separator airtight tank 1 at one time through the inert solid particle inlet 14, and the high-concentration landfill leachate (or electroplating wastewater, heavy metal wastewater) at normal temperature ) after metering, enter the condensed water preheater 16 to increase the temperature of the feed liquid (preheated to the evaporation temperature) through the feed pump 15, enter the flotation device 7, pass through the discharge circulation pump 8, enter the feed pipe 6 and then enter the feed liquid Nozzle 2, the heated high-concentration landfill leachate is evenly distributed on the heating pipe 3 under the action of the feed liquid nozzle 2, and the steam compressor 11 is turned on at the same time, the heated high-concentration landfill leachate (or electroplating wastewater, heavy metal wastewater ) is evaporated and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com