Preparation method of VO2(M) nano powder and film through spray pyrolysis

A nano-powder, VO2 technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of long synthesis cycle and increased production cost, and achieve short synthesis cycle, low cost, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

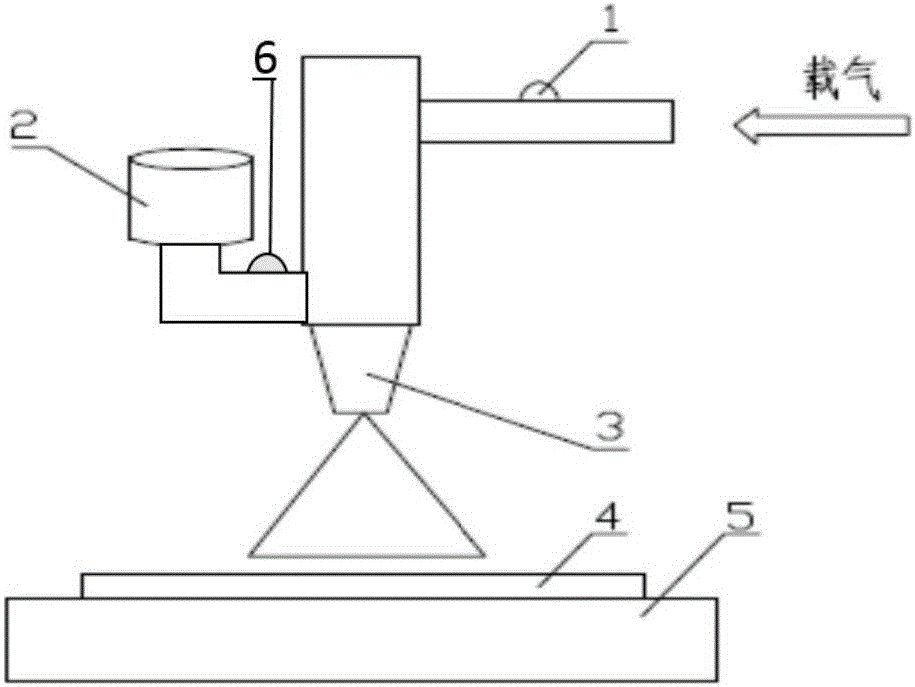

Method used

Image

Examples

Embodiment 1

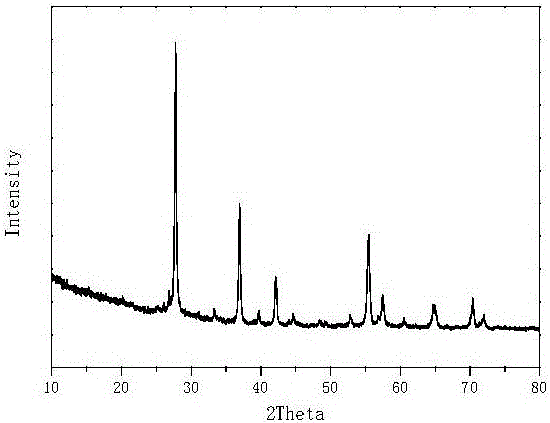

[0035] (1) Prepare an ethylene glycol solution of 0.2mol / L ammonium metavanadate and heat it to 20°C and stir for 200 minutes to obtain a transparent precursor solution; (2) Use a ceramic sheet as the substrate and heat it to 240°C with an electric constant temperature heating plate; (3) The distance from the atomizer nozzle to the substrate is adjusted to 8cm, and the carrier gas N 2 Velocity is 0.36m 3 / h, the spraying time is 300s, and VO 2 (M) Nanopowder.

[0036] figure 2 Shown is the XRD of the product prepared under this condition, indicating that the vanadium dioxide prepared by this method is M phase.

Embodiment 2

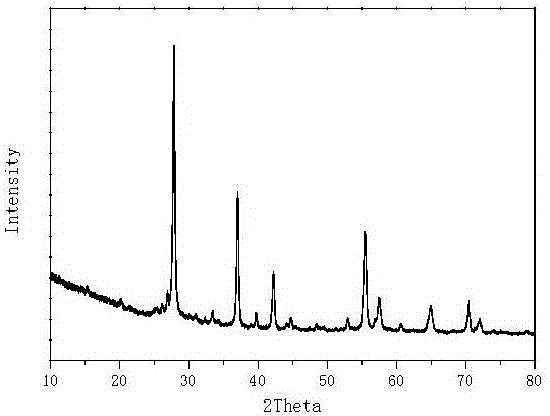

[0038] (1) Prepare ethylene glycol solution of 1mol / L ammonium metavanadate, heat to 80°C and stir for 30min, then cool to room temperature to obtain a transparent precursor solution; (2) Use a ceramic sheet as the substrate, and heat it to 260°C with an electric constant temperature heating plate ℃; (3) The distance from the atomizer nozzle to the substrate is adjusted to 15cm, and the carrier gas Ar flow rate is 1.2m 3 / h, the spraying time is 1200s, and VO 2 (M) Nanopowder.

[0039] image 3 Shown is the XRD of the product prepared under this condition, indicating that the vanadium dioxide prepared by this method is M phase.

Embodiment 3

[0041](1) Prepare an ethylene glycol solution of 0.5mol / L ammonium metavanadate, heat it at 95°C and stir for 5 minutes, and cool to room temperature to obtain a transparent precursor solution; (2) Use a ceramic sheet as the substrate and heat it to 280 ℃; (3) The distance from the atomizer nozzle to the substrate is adjusted to 10cm, and the carrier gas N 2 Velocity is 0.05m 3 / h, spraying time 720s, that is, get VO 2 (M) Nanopowder.

[0042] Figure 4 Shown is the XRD of the product prepared under this condition, indicating that the vanadium dioxide prepared by this method is M phase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com