Bobbin insertion system of automatic bobbin winder and bobbin insertion method

An automatic winder and intubation technology, which is applied in the directions of sending objects, conveying filamentous materials, thin material processing, etc., can solve the problems of intubation capacity restricting overall efficiency, unacceptable to textile enterprises, and high use and maintenance costs. Achieve the effect of improving intubation efficiency, reducing equipment manufacturing cost and manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

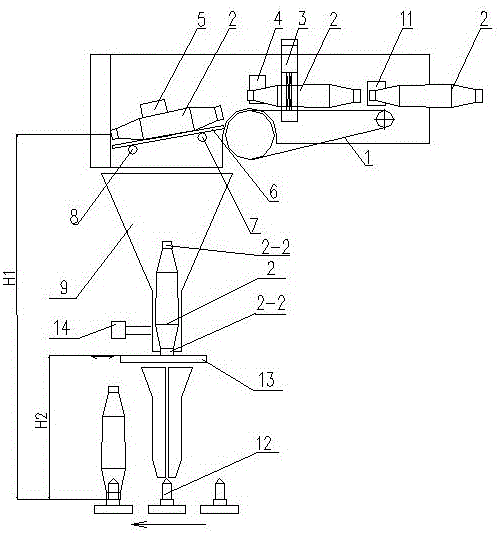

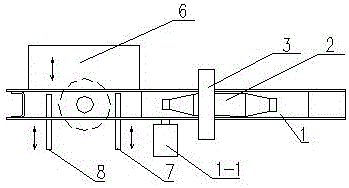

[0025] The present invention is described in further detail below in conjunction with accompanying drawing:

[0026] see figure 1 , figure 2 , an embodiment of an automatic winding machine intubation system of the present invention, including a control system, a bobbin conveying device, a bobbin size judgment device, a bobbin releasing device arranged near the output end of the bobbin conveying device, and a fixed funnel 9. Movable funnel 10, tray channel and tray 12. A telescopic baffle 13 is arranged between the fixed hopper 9 and the movable hopper 10, and the telescopic baffle 13 is connected with a driving mechanism, and a sensor 14 for detecting whether there is bobbin is arranged near the fixed hopper 9, and the sensor 14 is connected with the control system connection. The driving mechanism is controlled by the control system to drive the telescopic baffle 13 to block or evacuate the lower port of the fixed funnel 9, and the bobbin 2 entering the fixed funnel 9 sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com