Naphthalene tank breathing valve enhanced cooling crystallization scraping device

A technology of cooling crystallization and scraping device, applied in the directions of packaging, transportation, packaging, containers, etc., can solve the problem of crystalline naphthalene clogging the breathing valve, etc., and achieve the effect of preventing crystallization clogging, easy to implement, and simple in structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

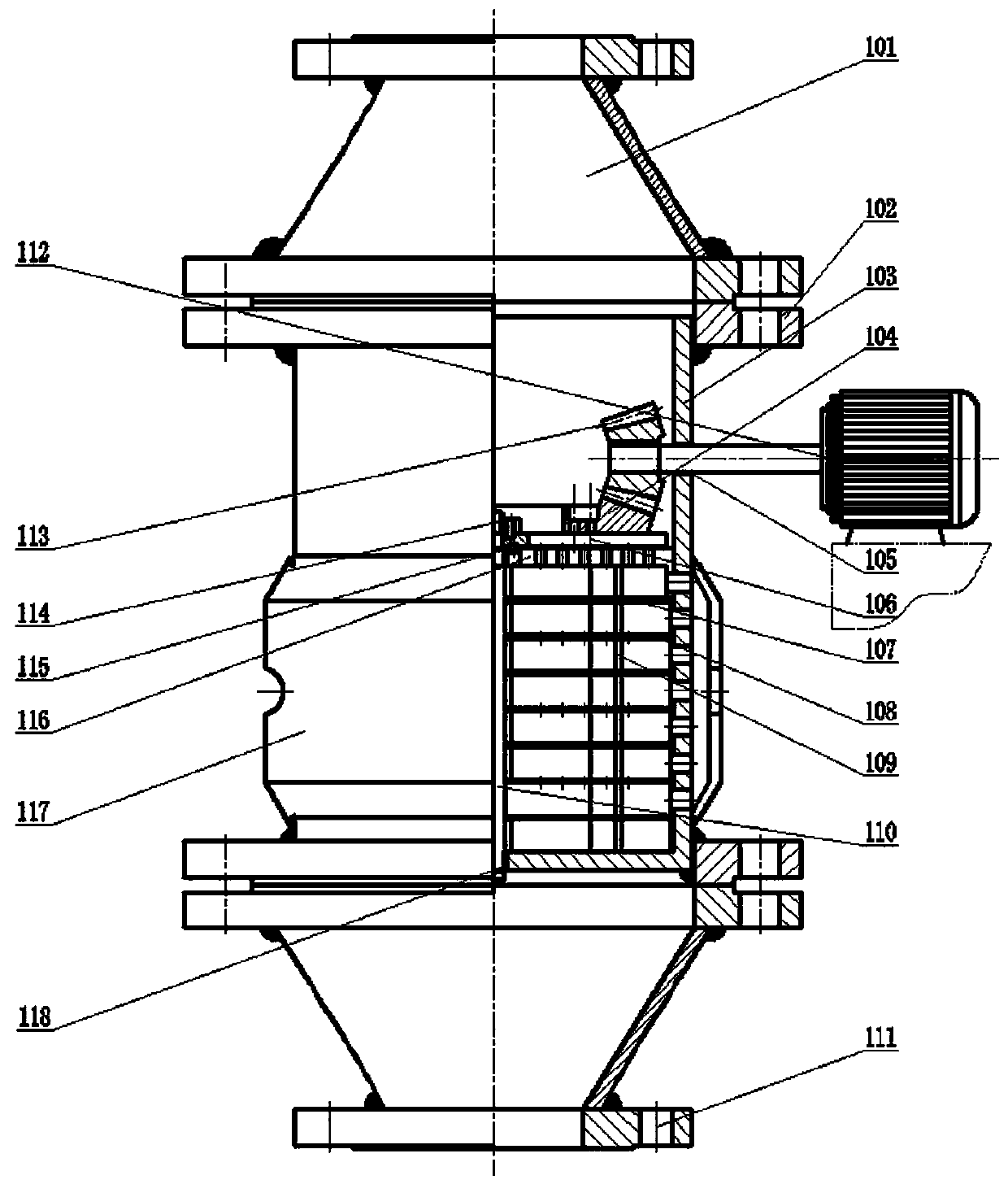

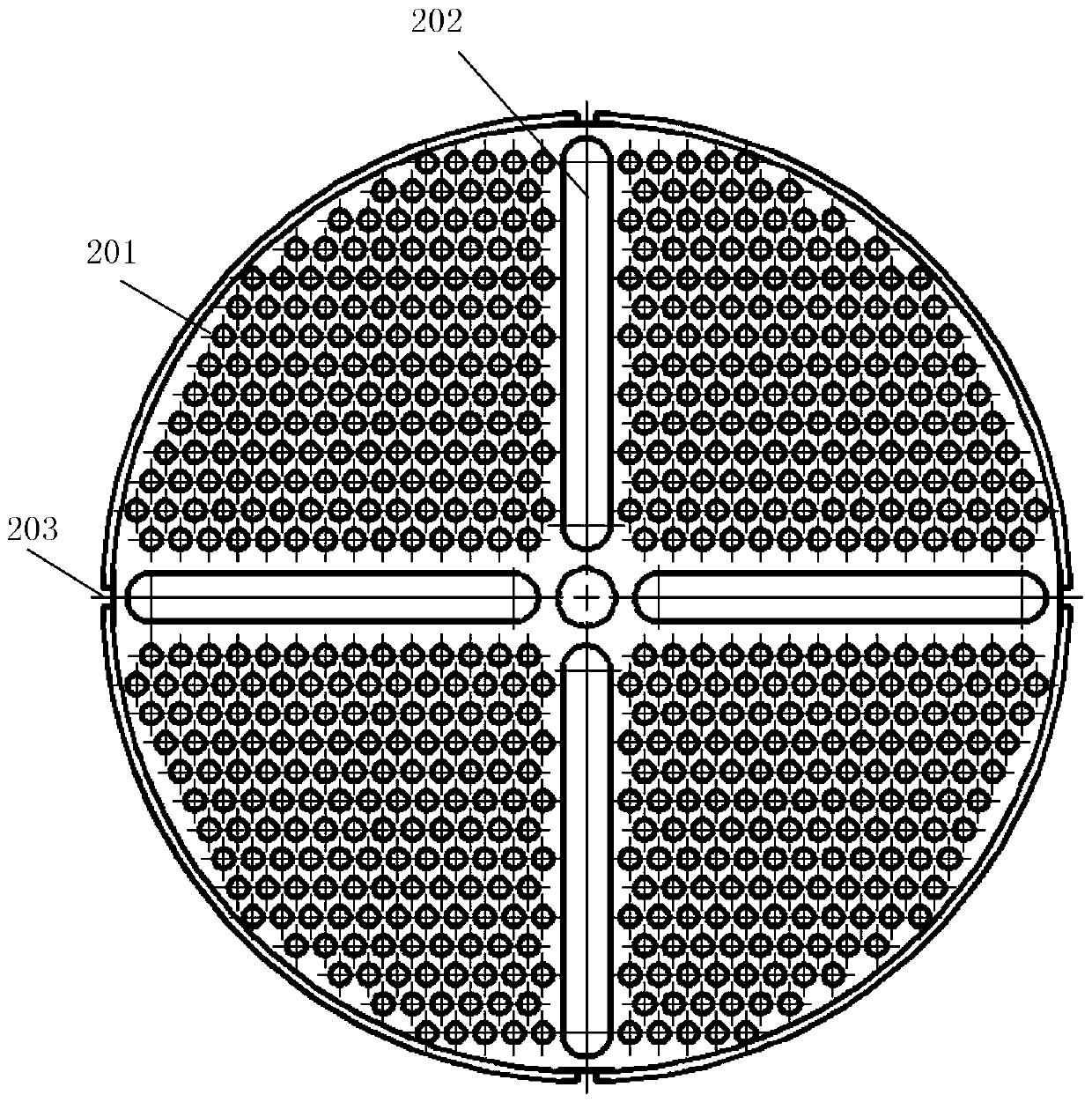

[0031] As shown in the figure, the naphthalene tank breathing valve strengthened cooling and crystal scraping device, including sieve plate, scraper, cylinder, main shaft, ring gear, gear and reduction motor, the bottom of cylinder 103 is welded with a cross support structure, cylinder 103 There is a round hole in the middle of the bottom. The round hole is equipped with a needle bearing 118. The main shaft 110 is installed in the needle bearing. The screen plate and the scraper are interlaced on the main shaft to form a multi-layer structure. There is an embedded structure between the scraper and the main shaft. , There is an engagement structure between the edge of the screen plate and the inner wall of the cylinder; the reduction motor 112 is installed on the outer wall of the cylinder, the bevel gear 113 is installed on the reduction motor shaft, the bevel gear 113 meshes with the ring gear 104, and the ring gear 104 The top scraper 106 is connected to the topmost top scrape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com