Bevel guide rail plate-shearing machine and shearing method thereof

A technology of shearing machine and guide rail, which is applied in the direction of shearing device, shearing machine equipment, cutter for shearing machine device, etc., to achieve the effect of high-efficiency automatic shearing, improved production efficiency and low frictional force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

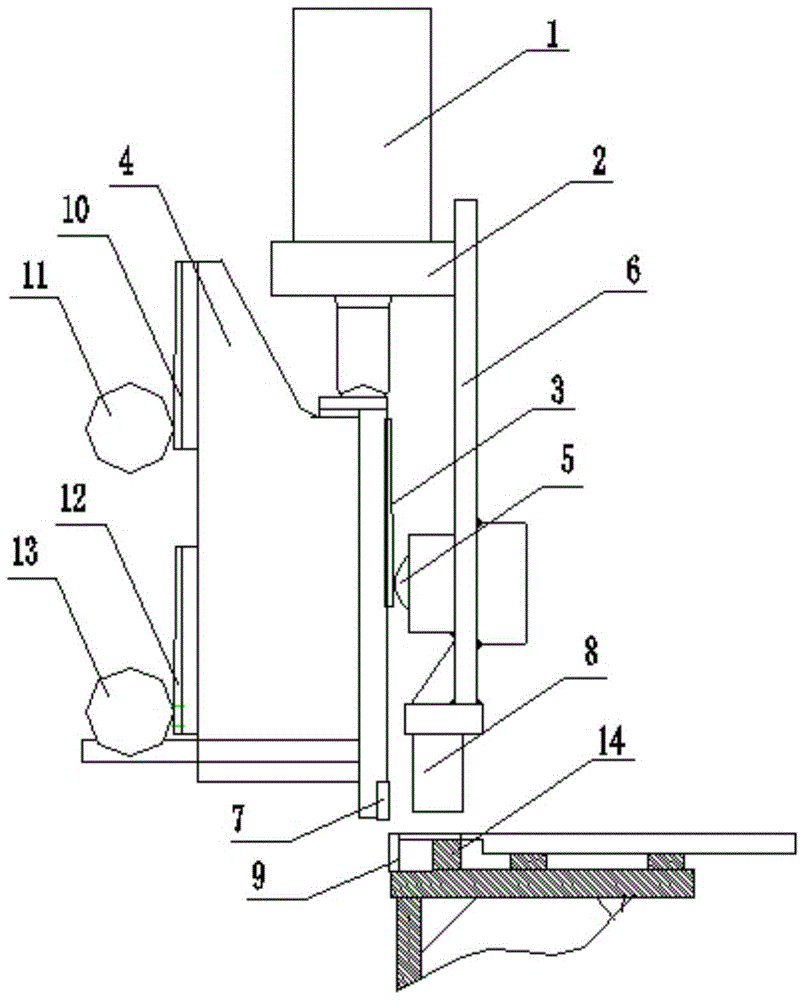

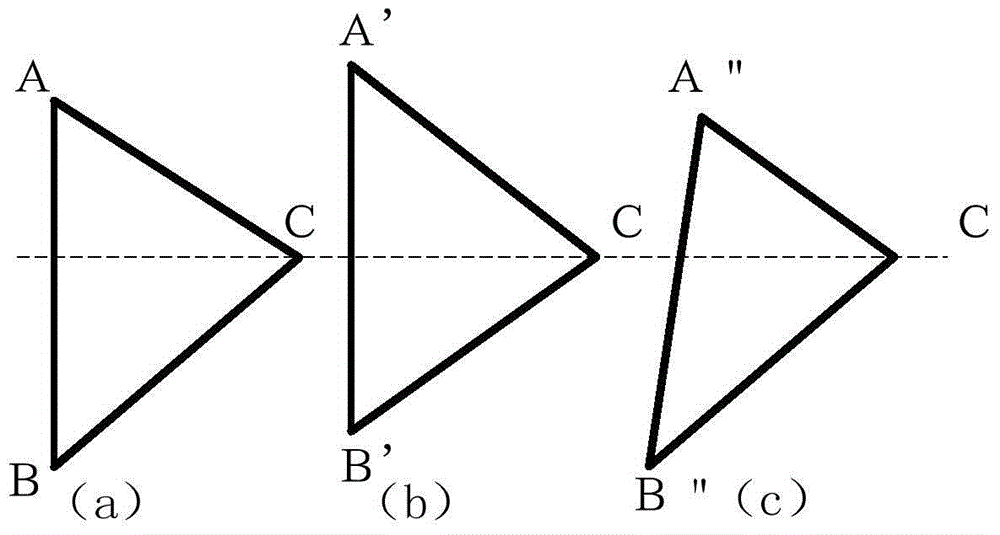

[0053] combine Figure 1-4 , a kind of slope guide rail shearing machine, it comprises pressure beam 6, upper blade 7, lower blade 9, knife rest 4 and feed support 14, the bottom of knife rest 4 is provided with upper blade 7, lower blade 9 and feed Support 14 is all arranged on the shearing machine platform, and the right side of knife rest 4 is provided with front guide rail 3, and the left side of knife rest 4 is provided with rear upper guide rail 10 and rear lower guide rail 12, and front guide rail 3 1. The angle between the guide rail surface of the rear upper guide rail 10 and the rear lower guide rail 12 and the tool holder 4 is α, the front guide rail 3 is connected with the front roller 5 arranged on the left side of the binder beam 6, and the rear upper roller The wheel 11 and the rear lower roller 13 move simultaneously. The rear upper roller 11 and the rear lower roller 13 move at the same time, so that the knife rest 4 does not rotate, but only moves in the ver...

Embodiment 2

[0073] Such as figure 1 , in this embodiment, a kind of slope guide rail shearing machine is installed with a camera in the cutting site workshop and connected with the controller. The controller saves the data captured by the camera and displays it in real time on the man-machine interface. The structure is the same Embodiment 1, a kind of shearing method of inclined-plane guide rail shearing machine, its steps are:

[0074] A, build described a kind of inclined-plane guide rail shearing machine, set and keep vertical between upper blade 7 and lower blade 9;

[0075] B. Input the thickness value of the plate to be cut into the man-machine interface, the controller sets the slope of the guide rail surface to 1:0.06 according to the thickness value of the plate, and calculates the horizontal gap between the upper blade 7 and the lower blade 9 set value;

[0076] C. The controller adjusts the slope of the guide rail surface to 1:0.06;

[0077] The following steps are the same...

Embodiment 3

[0079] This embodiment is the same as Embodiment 2, wherein the slope of the guide rail surface is 1:0.08.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com