Sulfur-free processing method for primary-taste and primary-color dried jack fruits

A technology for jackfruit and jackfruit is applied in the field of sulfur-free processing of original and primary color dried jackfruit, which can solve the problems of affecting product quality, high reducing sugar ratio, difficulty in retention, etc. The effect of nutrient content and flavor destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

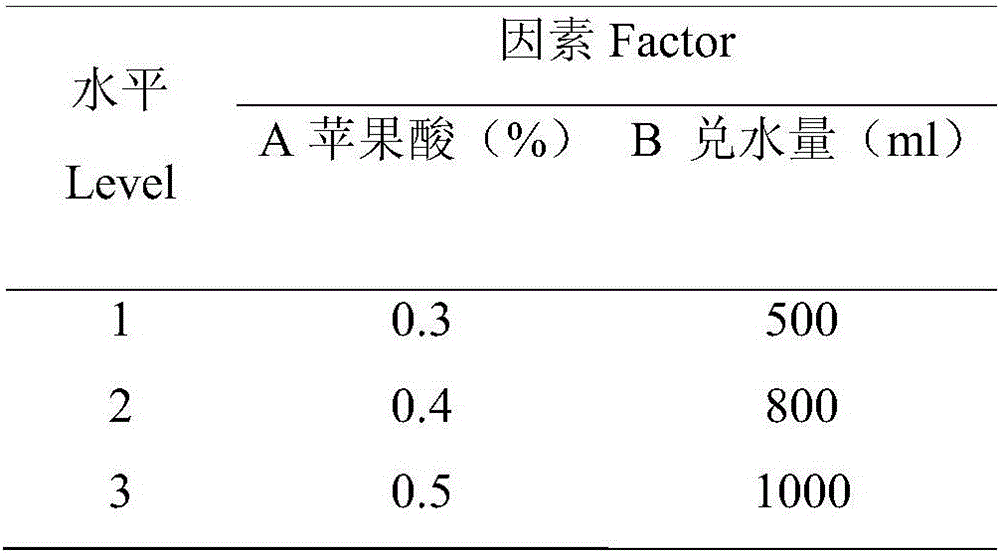

[0038] Embodiment 1 The selection of the sulfur-free processing technology of the original taste and original color pineapple dried fruit of the present invention

[0039] 1. Selection of jackfruit raw material varieties and maturity

[0040] The jackfruit varieties currently on the market mainly include jackfruit with dry buds and yellow flesh, jackfruit with wet buds and red flesh, and jackfruit with dry buds and yellow flesh. Because it is difficult to obtain complete buds from jackfruit with wet buds and yellow flesh, it is not suitable for processing, so dry bud yellow is selected. The two kinds of jackfruit with meat and dry bracted red meat are the raw materials for trial production, and the three levels are green ripe (6-7 ripe), fully ripe (8-9 ripe), and overripe, respectively in terms of flavor retention, cutting and shaping, and processing performance. Correlation research with multi-factors such as morphological characteristics, observation and measurement of ja...

Embodiment 2

[0095] Embodiment 2 uses the method of the present invention to process original taste and primary color pineapple dried fruit

[0096] Ripening: Put 100kg of purchased pineapple at 35°C for 4 days at a constant temperature to accelerate the ripening, so that the sugar content of the pineapple husk reaches 16BX, and the maturity reaches 8-9 maturity. Cut the ripened pineapple into slices, and the obtained jackfruit pulp is firm , bright color, and the finished product is complete in flakes.

[0097] Joint treatment of sterilization, enzyme removal and color protection: Take 30L of clean water, add 0.4% (120g) of D-sodium erythorbate according to the quality of the clean water to make a solution, heat the solution to 85°C and blanch the jackfruit slices for 3 minutes to kill harmful microorganisms , remove the activity of the enzyme, and at the same time maintain the hardness of the jackfruit pulp and the color of the original fruit, achieving the purpose of sterilizing the e...

Embodiment 3

[0100] Embodiment 3 Use the method of the present invention to process the original taste and color pineapple dried fruit

[0101] Ripening: Put 100kg of purchased jackfruit at 32°C for 4 days at a constant temperature to accelerate ripening, so that the sugar content of the jackfruit bracts reaches 16BX, and the maturity reaches 8-9 maturity, and the ripened jackfruit is cut into slices.

[0102] Joint treatment of sterilization, enzyme removal and color protection: take 30L of clean water, add 0.4% (120g) of D-sodium erythorbate according to the quality of the clean water to make a solution, heat the solution to 83°C and blanch the jackfruit fruit slices for 3 minutes to kill harmful microorganisms, Removes enzyme activity.

[0103] Sulfur-free sugar immersion: Adding white granulated sugar directly to increase the sugar content step by step intermittent forced circulation sugar icing method at room temperature without sulfur icing for 24 hours, the initial sugar content o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com