Preparation method of fermented acanthopanax tea

A technology of Acanthopanax senticosus tea and Acanthopanax senticosus leaves, which is applied in the field of preparation of fermented Acanthopanax senticosus tea, can solve the problems of the loss of flavonoids in Acanthopanax senticosus leaves, the decline in the quality of Acanthopanax senticosus tea, and the difficulty in controlling the temperature. Improve the content and quality stability, overcome the effect of high drying energy consumption and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

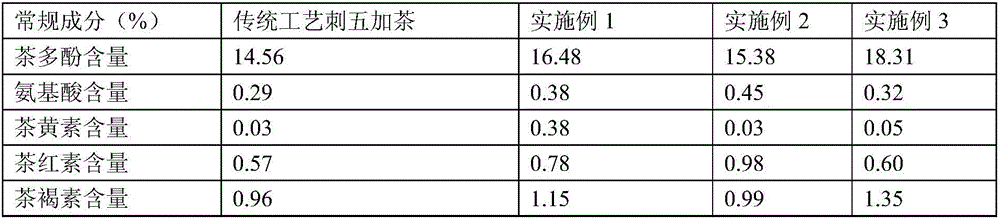

Examples

Embodiment 1

[0038] (1), picking

[0039] Pick the leaves of Acanthopanax senticosus planted in mid-April from July to August;

[0040] (2), withering

[0041] After picking, 400g of cleaned Acanthopanax leaves were placed in a microwave tunnel dryer with a microwave power of 1000W, the temperature was controlled at 36°C, and the processing time was 10 minutes to obtain Acanthopanax leaves with a moisture content of 80%;

[0042] (3) Finished

[0043] Use a microwave tunnel dryer to deenzyme the withered Acanthopanax acanthopanax leaves, the microwave power is 1500W, the temperature is controlled at 60°C, the conveyor belt speed of the tunnel microwave drying equipment is controlled at 5m / min, and the deenzyme time is 1min;

[0044] (4) kneading

[0045] Moderately knead the finished Acanthopanax leaves for 30 minutes, and knead the cell liquid of the Acanthopanax leaves to the surface of the leaves, which is beneficial to contact with the coronoids and promote the fermentation;

[004...

Embodiment 2

[0053] (1), picking

[0054] Pick the leaves of Acanthopanax senticosus planted in mid-April from July to August;

[0055] (2), withering

[0056] After picking, 200g of cleaned Acanthopanax leaves were placed in a microwave tunnel dryer with a microwave power of 1500W, the temperature was controlled at 34°C, and the processing time was 30 minutes to obtain Acanthopanax leaves with a moisture content of 80%;

[0057] (3) Finished

[0058] Use a microwave tunnel dryer to deenzyme the withered Acanthopanax acanthopanax leaves, the microwave power is 2000W, the temperature is controlled at 70°C, the conveyor belt speed of the tunnel microwave drying equipment is controlled at 0.4m / min, and the deenzyme time is 3min;

[0059] (4) kneading

[0060] Moderately knead the finished Acanthopanax leaves for 30 minutes, and knead the cell liquid of the Acanthopanax leaves to the surface of the leaves, which is beneficial to contact with the coronoids and promote the fermentation;

[0...

Embodiment 3

[0068] (1), picking

[0069] Pick the leaves of Acanthopanax senticosus planted in mid-April from July to August;

[0070] (2), withering

[0071] After picking, 200g of cleaned Acanthopanax leaves were placed in a microwave tunnel dryer with a microwave power of 1200W, the temperature was controlled at 38°C, and the processing time was 20 minutes to obtain Acanthopanax leaves with a moisture content of 76%;

[0072] (3) Finished

[0073] Use a microwave tunnel dryer to deenzyme the withered Acanthopanax acanthopanax leaves, the microwave power is 1800W, the temperature is controlled at 65°C, the conveyor belt speed of the tunnel microwave drying equipment is controlled at 2m / min, and the deenzyme time is 22min;

[0074] (4) kneading

[0075] Moderately knead the finished Acanthopanax leaves for 30 minutes, and knead the cell liquid of the Acanthopanax leaves to the surface of the leaves, which is beneficial to contact with the coronoids and promote the fermentation;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com