Impedance matching method for plasma processing device

A processing device and impedance matching technology, applied in semiconductor/solid-state device manufacturing, discharge tubes, electrical components, etc., can solve the problems of poor plasma treatment process uniformity, poor uniformity of plasma distribution density, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] As mentioned in the background art, the existing impedance matching method will result in poor uniformity of plasma distribution density in the plasma treatment process, resulting in poor uniformity of the plasma treatment process.

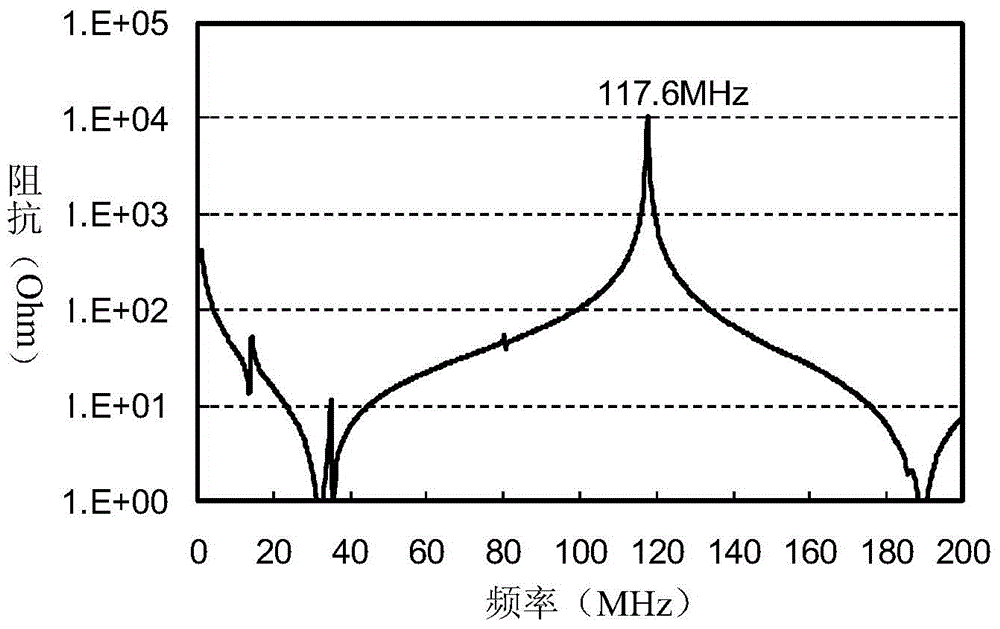

[0040] After research, it is found that in the case of fixed external matching network parameters, only adjusting the output frequency of the RF power supply has the following advantages: figure 1 The frequency characteristics shown. A reaction chamber for performing a plasma treatment process generally has an eigenfrequency, and in a range around the eigenfrequency, the impedance of the reaction chamber increases sharply, specifically as figure 1 as shown, figure 1 It is a schematic diagram of the relationship between the frequency and the blocking of the reaction chamber.

[0041] Please refer to figure 1 , when the frequency is 117.6 MHz, the impedance of the reaction chamber reaches a peak value of 10000 ohms, therefore, the frequenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com