A railway train anti-skid exhaust valve with one-way valve

A technology of one-way valve and air exhaust valve, which is applied in the direction of valve operation/release device, control valve, valve device, etc., which can solve the problems of alleviating adverse effects, damage to wheels, and compressed air cannot be completely emptied, so as to improve The effect of mitigating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

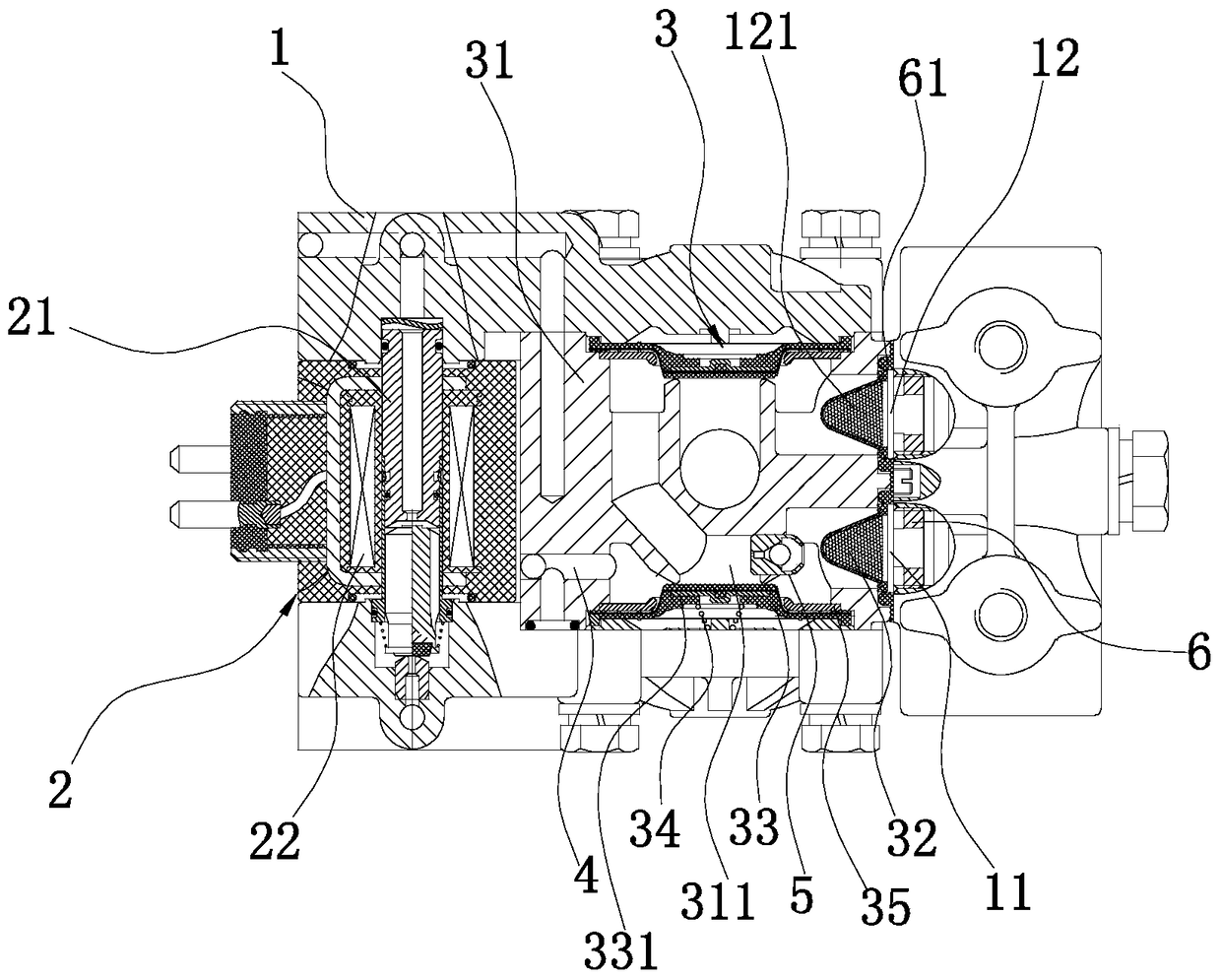

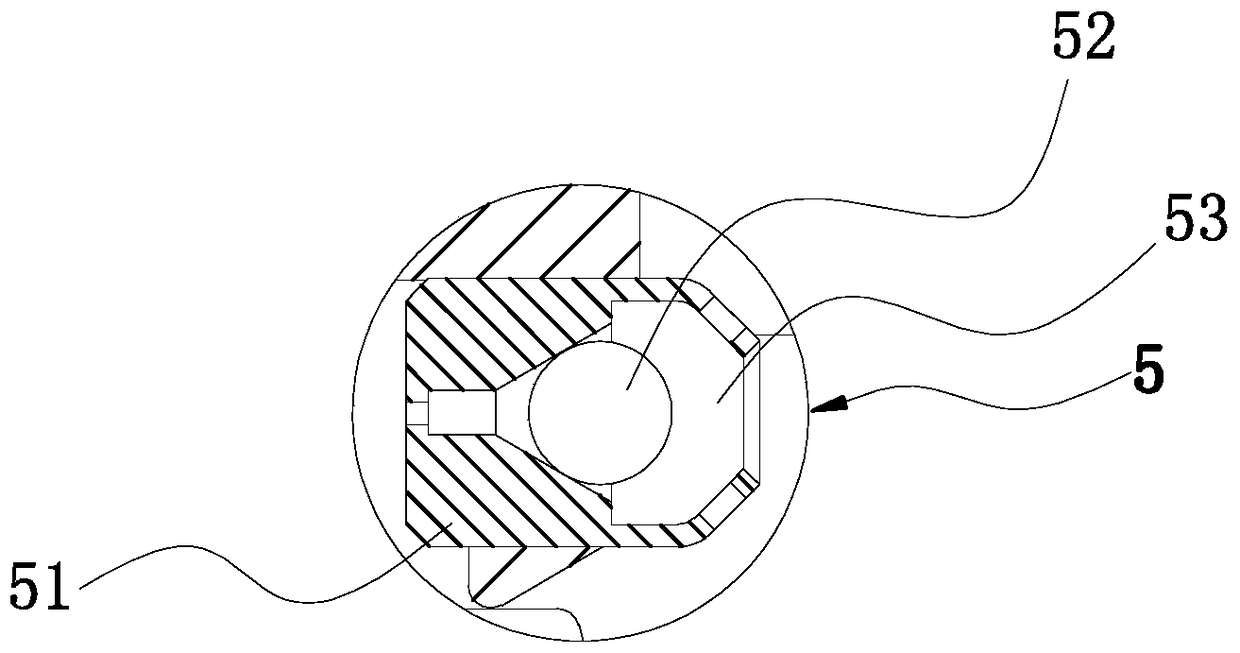

[0016] like Figure 1~2 As shown, the present invention discloses an anti-skid exhaust valve for railway trains with a one-way valve, which includes a housing 1 and an electromagnetic control assembly 2 and an adjustment assembly 3 arranged in the housing 1 . The electromagnetic control assembly 2 and the adjustment assembly 3 communicate through a connecting pipe 4 . The electromagnetic control assembly 2 includes an encapsulated coil 21 and an iron core assembly 22 , and the iron core assembly 22 is installed in the encapsulated coil 21 . The adjustment assembly 3 includes a valve body 31 , an inlet mesh cover 32 , a diaphragm 33 and a return spring 34 . The diaphragm 33 contains an iron sheet 331 to support the diaphragm 33 . The casing 1 is provided with an air inlet 11 and an air outlet 12 . The inlet mesh cover 32 is installed at the air inlet 11 , and the outlet mesh cover 121 is installed at the air outlet 12 . The return spring 34 is located between the diaphragm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com