Oil charging accurate control method for wet clutch

A wet clutch, precise control technology, applied in clutch, transmission control, components with teeth, etc., can solve the problem of not considering the influence of oil filling pressure and filling time, not considering the influence of solenoid valve current hysteresis, etc. Achieve the effect of shortening the oil filling time, fast and accurate clutch oil filling process, and improving the response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

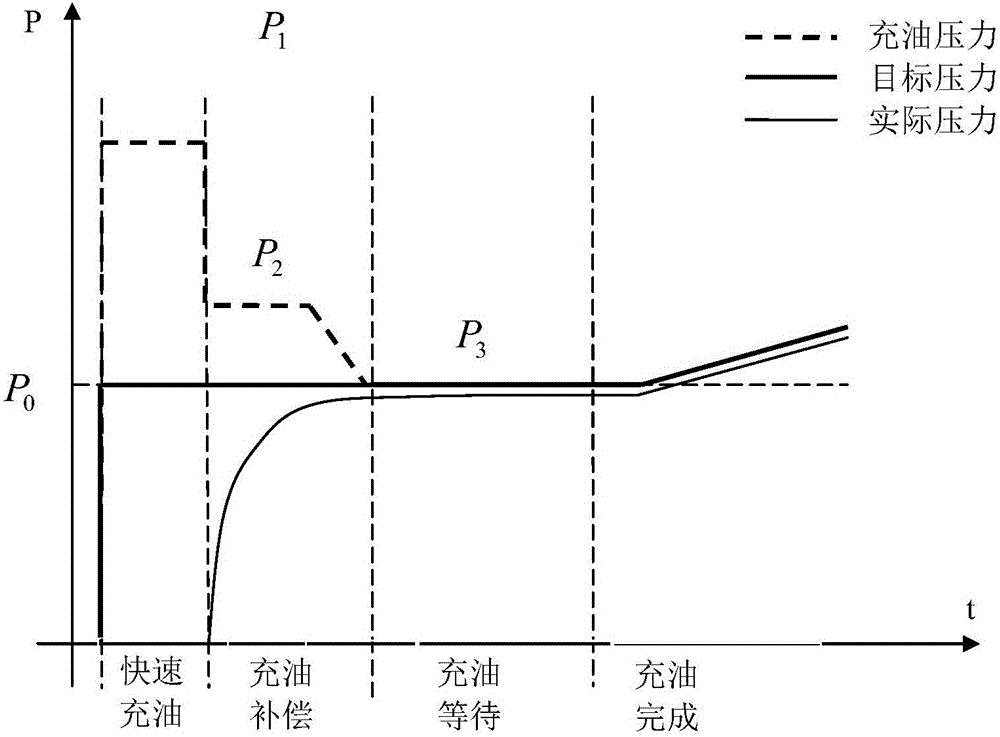

[0022] exist figure 1 In the process, the whole filling process is divided into four stages:

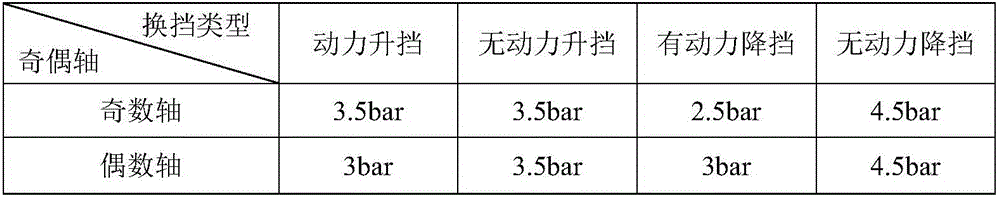

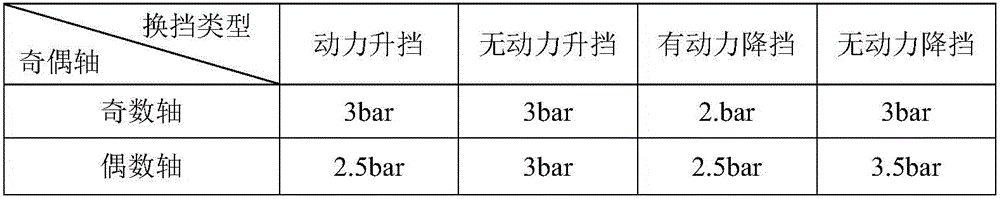

[0023] Stage 1: Quickly fill the clutch with oil filling pressure P 1 =P 0 +ΔP 1 , P 0 is the final target pressure of the clutch, ΔP 1 It is an additional command pressure added on the basis of the target pressure in order to realize fast oil filling and make the clutch pressure build up quickly. Different gearbox oil temperatures and different shift types will affect the effect of quick oil filling, so the pressure can be obtained from the table according to the gearbox oil temperature and shift type, for example, as shown in the table below; the oil filling time is based on the current system pressure Determined with the shift type, this stage is mainly to improve the response speed of the solenoid valve,

[0024] -30℃△P 1 check table

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com