Hole drilling and slot expanding equipment

An equipment and drill pipe technology, applied in the field of engineering equipment, can solve the problems affecting the progress of engineering construction, the difficulty of construction, and the large deviation, and achieve the effects of facilitating disassembly, improving adhesion strength, and enhancing the ability to resist external forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

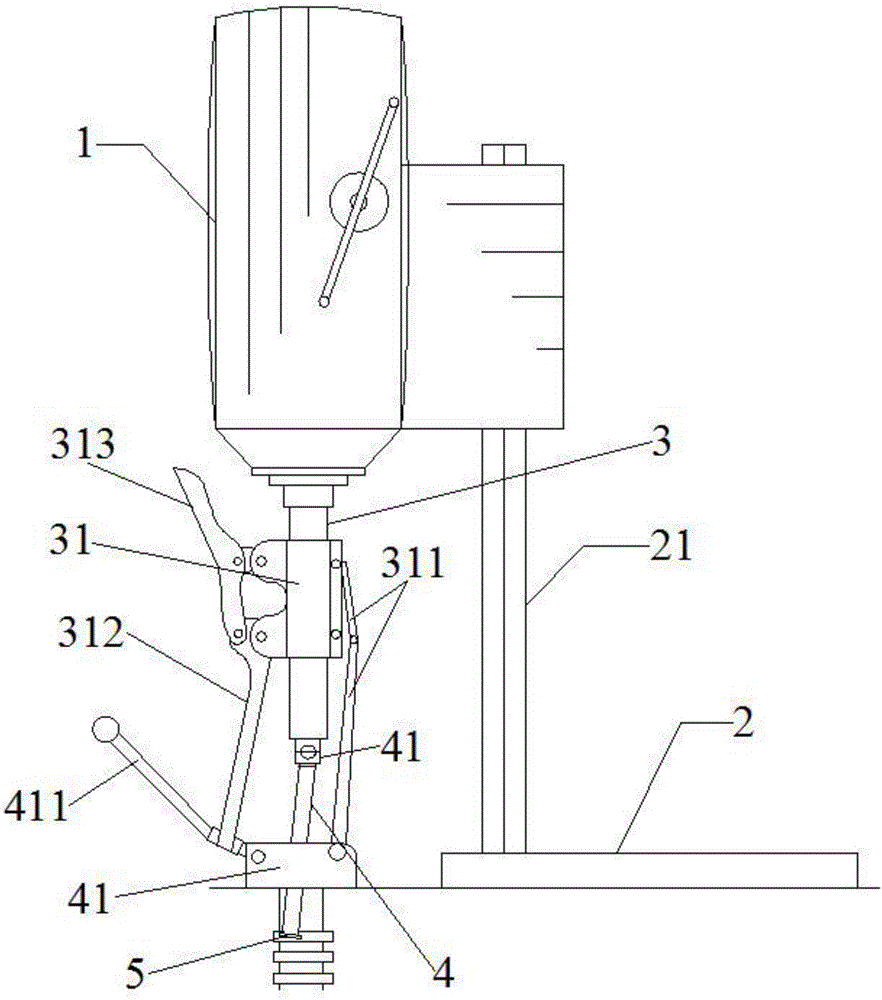

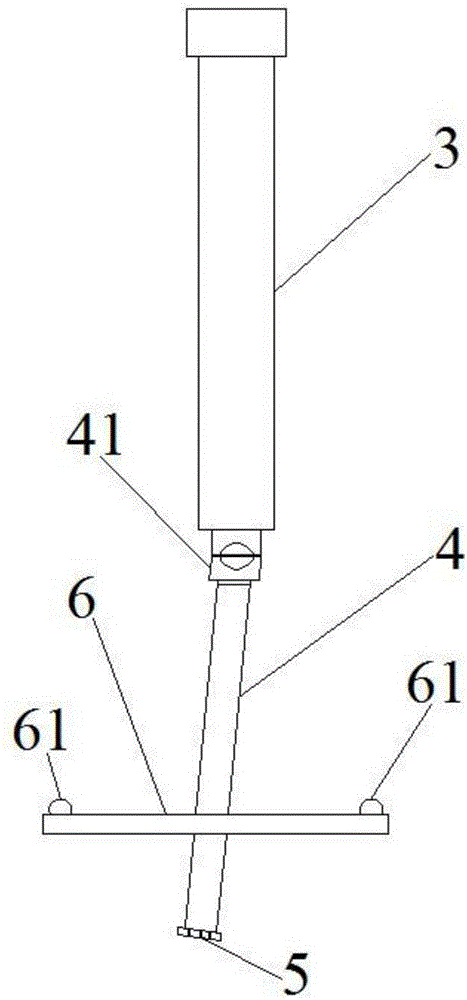

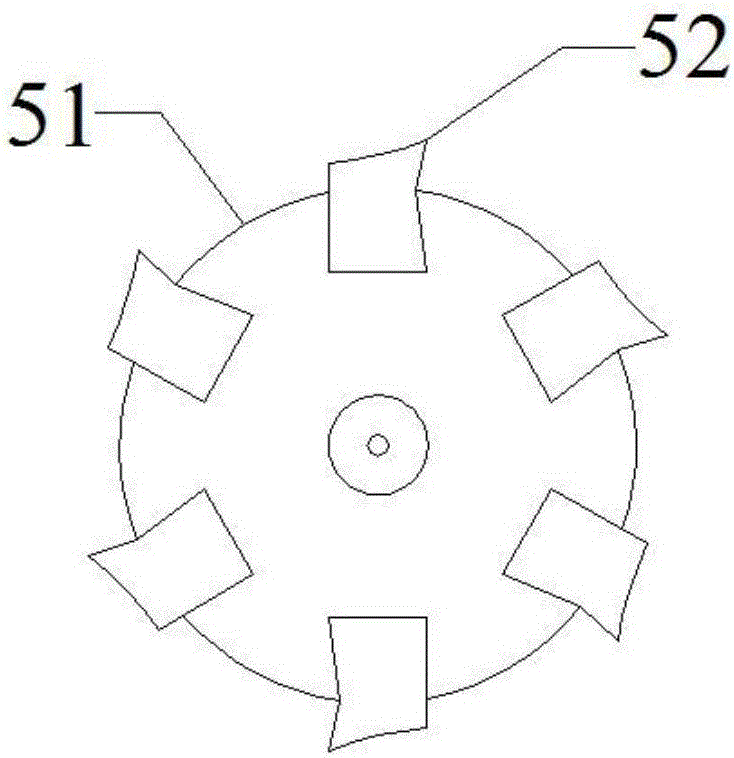

[0019] Such as figure 1 , 2 Shown in and 3, a kind of drilling, expansion equipment, comprise drilling machine 1, support frame 2, connecting rod 3, drilling rod 4 and drill bit 5, support frame 2 is provided with slide rail 21, and drilling machine 1 passes slide rail 21 and The support frame 2 is connected, and through the guidance of the slide rail 21, the drilling machine 1 can move up and down. The drilling rod 4 is connected with the drilling machine 1 through the connecting rod 3. A universal joint 41 is arranged, and a guiding device is also provided on the drill rod 4 .

[0020] In order to improve the safety of the present invention, the guiding device includes a guide rod 41 sleeved on the drill pipe 4 through a copper bushing, a casing sleeve 31 sleeved on the connecting rod 3 , and one end of the guide rod 41 A linkage rod 311 is hinged on the side wall of the sleeve sleeve 31, and the other end of the guide rod 41 is fixedly connected with a guide handle 411, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com