Construction method for concrete diaphragm wall of deep bedrock

A construction method, the technology of ground connection wall, applied in the direction of foundation structure engineering, excavation, sheet pile wall, etc., can solve the problems of difficult construction, close to high-rise buildings, and the thickness of the wall passing through the hard bedrock, so as to ensure the quality of the project , Accelerate the progress of the project and save the cost of relocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

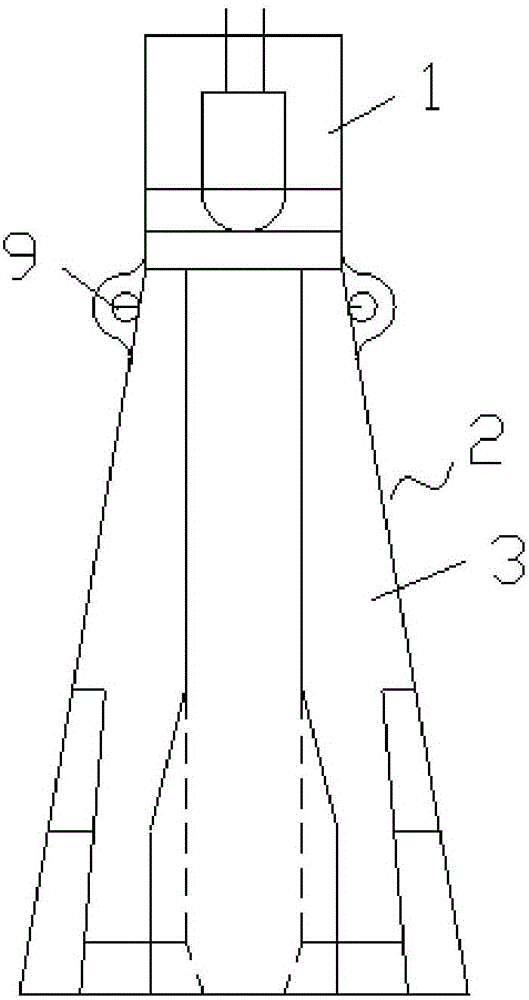

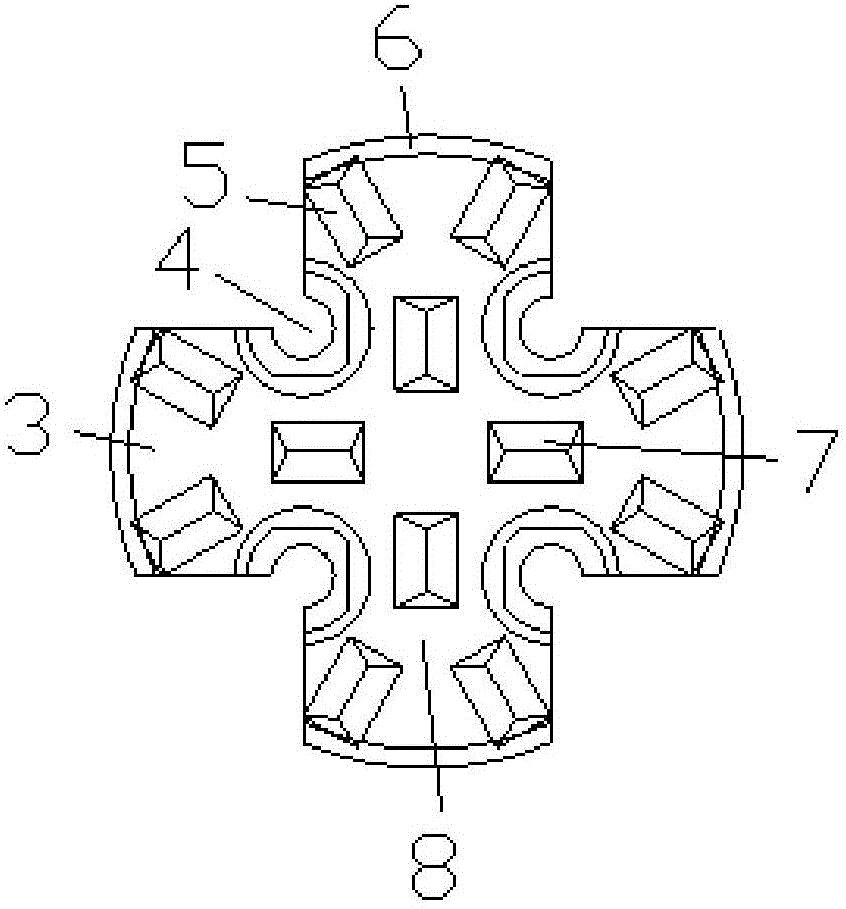

[0072] The inventor aims at the comprehensive geological conditions of the deep and hard bedrock with a few meters of cover layer, rock thickness of more than 20 meters, and high rock hardness (such as up to 132MPa) during building construction, and ultra-wide pipelines with a pipeline group width exceeding the drill bit diameter. Difficulties in ground connecting wall construction, combined with long-term experience accumulated in the building construction process, developed the construction method of the present invention that can solve the above-mentioned geological conditions during construction with low construction efficiency and long construction period.

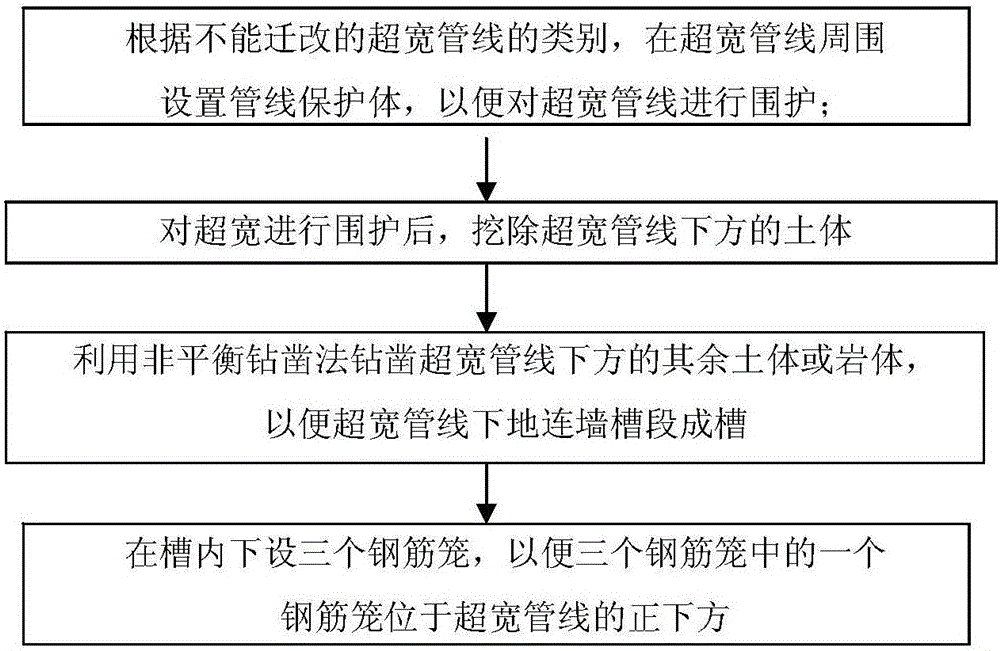

[0073] In the construction method of the deep and thick bedrock ground connecting wall provided by the present invention, when an ultra-wide pipeline that cannot be moved or modified occurs during construction, the following methods are used to construct the groove section of the ground connecting wall under the ultra-wide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com