Preparation method of multi-slit nanofiber aggregate yarn

A nanofiber, aggregate technology, applied in the direction of fiber processing, yarn, filament/thread forming, etc., can solve the problems of no further in-depth research and modification, inapplicability, etc., to achieve excellent mechanical properties and cost. Low, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

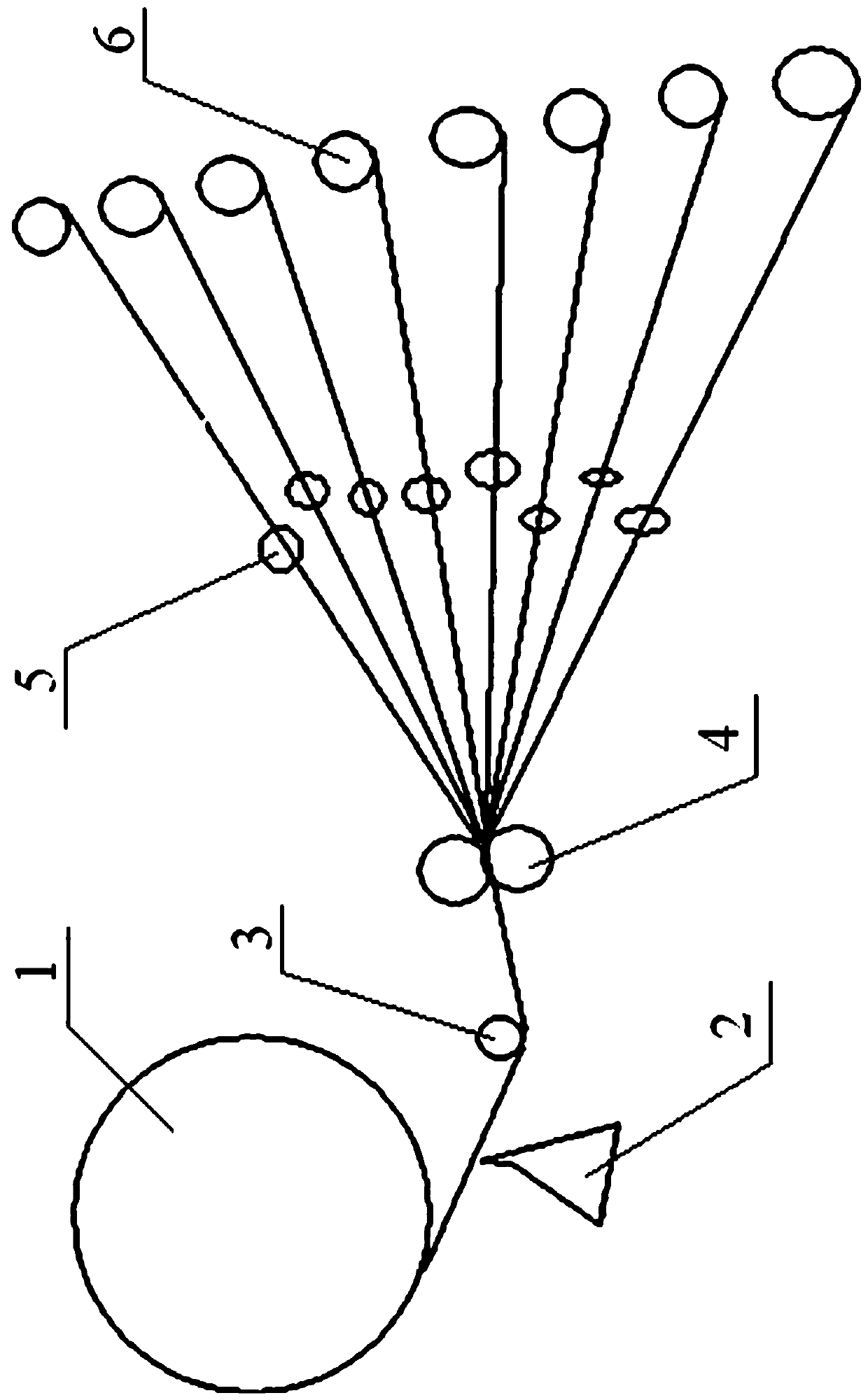

[0022] like figure 1 As shown, the preparation method of the multi-slit nanofiber assembly yarn in this embodiment includes the following steps: (1) package an ultra-thin PET / PA hot-melt resin with a diameter of 60 cm, a width of 100 mm, and a thickness of 30 μm The combined iridescent film 1 is unwound. During the unwinding process, a layer of titanium oxide nanotube water emulsion (containing 1% solid content) with a thickness of 5um is coated on the surface of the iridescent film by the slit coating head 2, and then passed through the guide roller 3. Use the ultrasonic blade module film slitting machine 4 to cut the iridescent film into 200 continuous non-dyed multicolored flat filaments with a width of 0.5mm at a speed of 80m / s; The fluid nozzle sprays air for twisting, the twist is 0 twist / 10 cm, and the heating device 5 heats the corresponding twisting point at 210 degrees to soften the continuous non-dyed multicolored flat yarn, and under the synergy of the winding devi...

Embodiment 2

[0025] The preparation method of the multi-slit nanofiber aggregate yarn in this embodiment includes the following steps: (1) A rainbow of ultra-thin PA / PET hot-melt resins with a package diameter of 60 cm, a width of 100 mm, and a thickness of 50 μm are combined. The film slitting machine with a mechanical rotary circular blade module cuts the iridescent film into 100 continuous non-dyed multicolored flat filaments with a width of 1.0mm at a speed of 100m / s; The fluid nozzle sprays air for twisting, with a twist of 100 twists / 10cm. At the same time, the heating device heats the corresponding twisting point at 180 degrees to soften the continuous non-dyed multicolored flat yarn. Under the synergy of the winding device, The continuous non-dyed multicolored flat yarn is stretched twice its length, and when the continuous non-dyed multicolored flat yarn is stretched and thinned to no color, it becomes an elliptical wire with a spiral twist, and the 200-layer film in the rainbow di...

Embodiment 3

[0028]The preparation method of the multi-slit nanofiber aggregate yarn in this embodiment includes the following steps: (1) A combination of ultra-thin PE / PET hot-melt resin with a package diameter of 60 cm, a width of 100 mm, and a thickness of 50 μm. The film is cut into 1000 continuous non-dyed multicolored flat filaments with a width of 0.1mm by a straight blade module film slitting machine at a speed of 200m / s; Twist, the twist is 1000 twists / 10 cm, and the heating device heats the corresponding twisting point at 210 degrees to soften the continuous non-dyed multicolored flat yarn, and under the synergy of the winding device, the continuous non-dyed multicolored flat The silk is stretched 5 times its length, and when the continuous non-dyed multicolored flat silk is stretched and thinned to no color, it becomes an oval silk with a spiral twist, and the thickness of the 200-layer film in the rainbow diaphragm is stretched The wavelength of the visible light (400-700nm) is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com