Smelting method for low-sulfur steel

A smelting method and technology for low-sulfur steel, applied in the field of metallurgy, can solve the problems of complex production process and high production cost of low-sulfur steel, and achieve the effects of improving the thermodynamic conditions of desulfurization and reducing the pressure of sulfur return.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

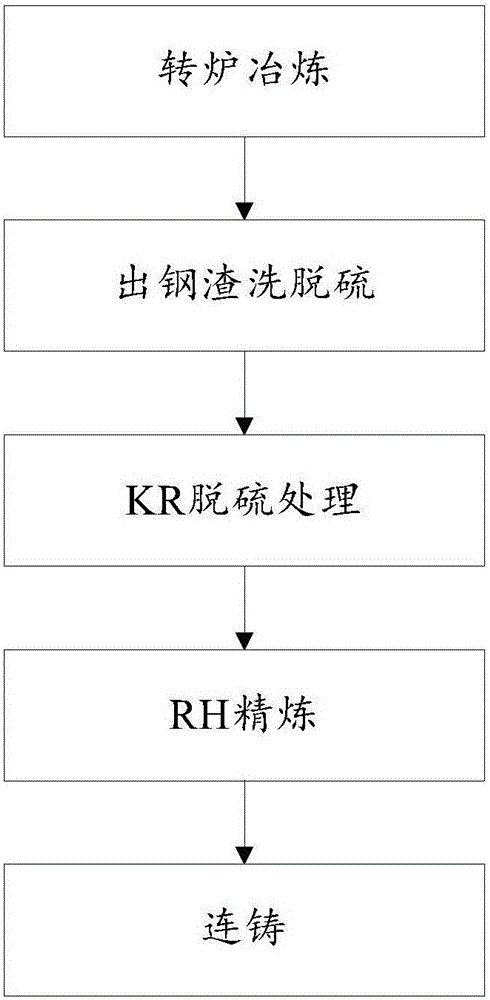

[0026] The low-sulfur steel smelting method provided in this example includes converter smelting, desulfurization of tapping slag, KR desulfurization treatment, RH refining and continuous casting process, wherein the converter is 300 tons.

[0027] During the converter smelting process, molten iron is added to the converter, and lime is added to the molten iron. The amount of lime added is 18,000kg / ton of steel. The binary basicity of the slag at the end of the converter is controlled to be 4.0, and the tapping temperature of the converter is controlled to be 1710°C.

[0028] In the process of removing sulfur from the steel slag, the slag blocking operation is adopted to control the thickness of the slag layer to ≤50mm. Add lime and fluorite before tapping 1 / 5, the amount of lime added is 3000kg, and the amount of fluorite added is 600kg. Add aluminum and iron for deoxidation when tapping 1 / 3 to 1 / 2, control the amount of aluminum and iron added according to the oxygen content...

Embodiment 2

[0031] The low-sulfur steel smelting method provided in this example includes converter smelting, desulfurization of tapping slag, KR desulfurization treatment, RH refining and continuous casting process, wherein the converter is 300 tons.

[0032] During the converter smelting process, molten iron is added to the converter, and lime is added to the molten iron. The amount of lime added is 6200kg / ton of steel. The binary basicity of the slag at the end of the converter is controlled to be 3.0, and the tapping temperature of the converter is controlled to be 1690°C.

[0033] In the process of removing sulfur from the steel slag, the slag blocking operation is adopted to control the thickness of the slag layer to ≤30mm. Add lime and fluorite before tapping 1 / 5, the amount of lime added is 1500kg, and the amount of fluorite added is 300kg. Add aluminum and iron for deoxidation when tapping 1 / 3 to 1 / 2, control the amount of aluminum and iron added according to the oxygen content a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com