Multi-air-duct star-shaped air supply device of coke dry quenching oven and method for cooling coke in coke dry quenching oven

A technology of air supply device and CDQ, which is applied in the cooling of coke, coke oven, petroleum industry, etc., can solve the problems of not achieving the fine control of CDQ and the inability to realize independent adjustment and control of CDQ temperature, etc. Improve the effect of uniform distribution, reasonable structure layout, and improved cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

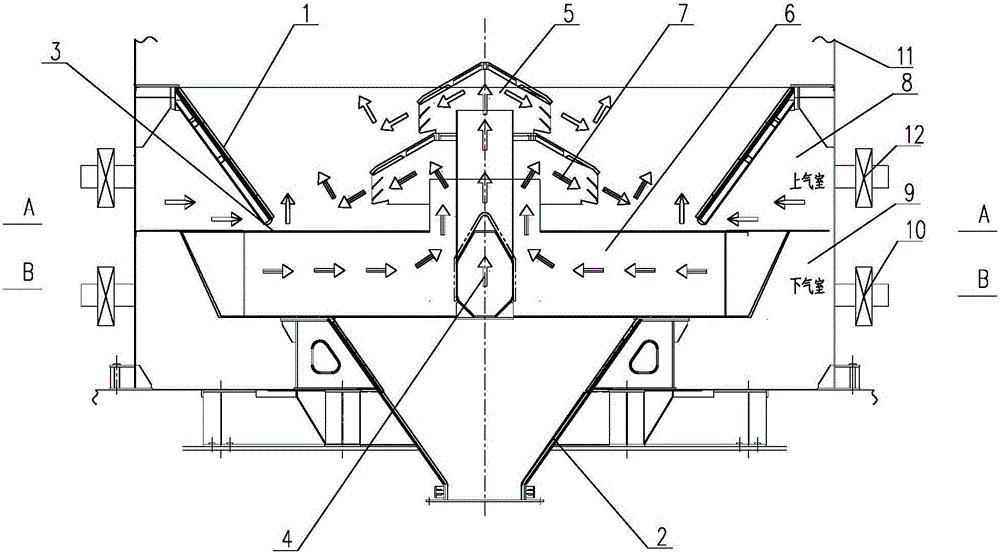

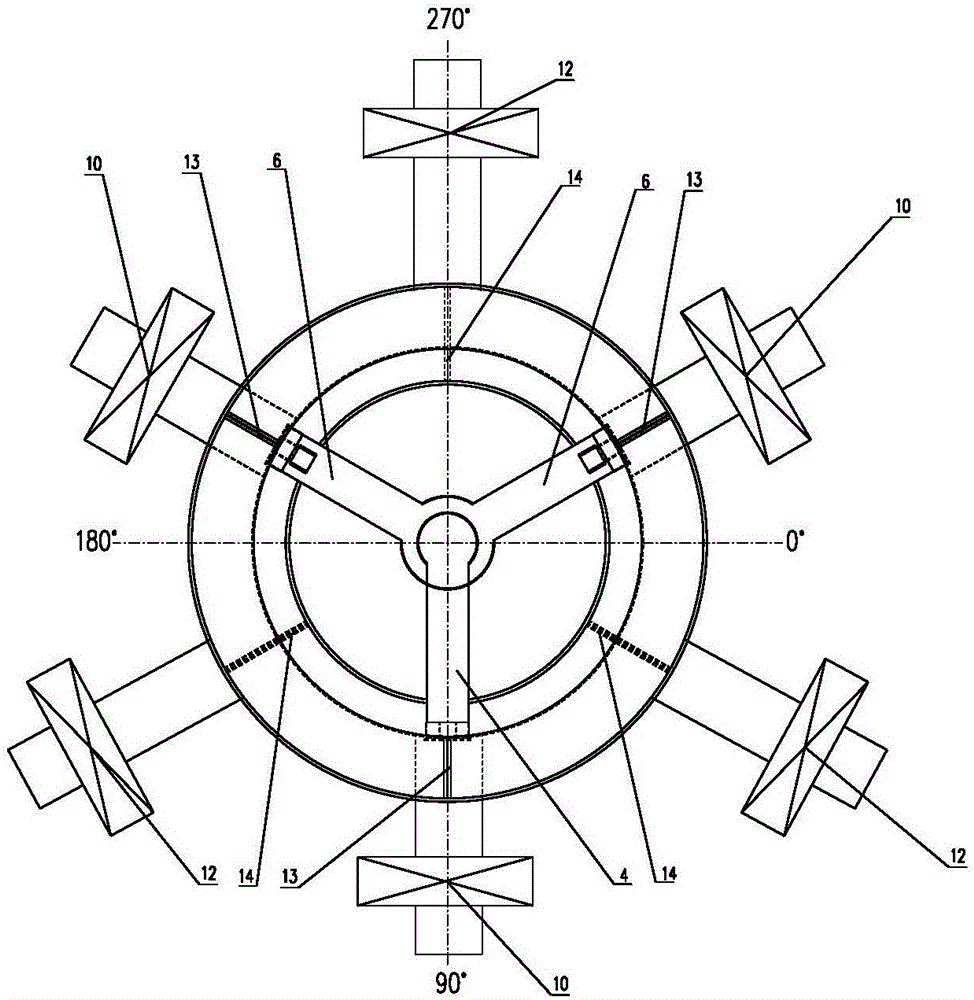

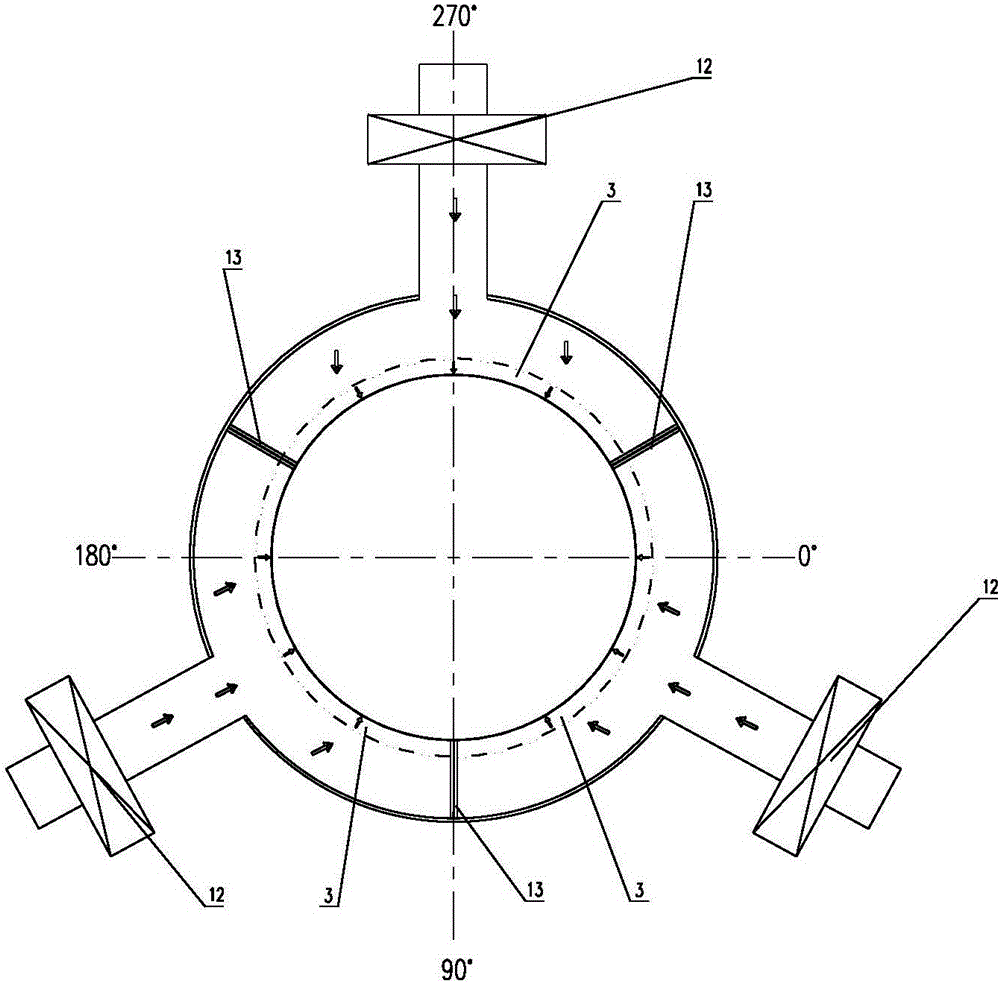

[0024] Such as figure 1 As shown, a CDQ furnace multi-channel star-shaped gas supply device according to the present invention includes a CDQ furnace shell 11, an upper cone bucket 1 and a lower cone bucket 2, and the upper cone bucket 1 and the lower cone bucket 2 The sleeves are inserted together, and the annular gap after the upper cone bucket 1 and the lower cone bucket 2 are inserted forms the annular air duct 3; the air chamber composed of the upper cone bucket 1, the lower cone bucket 2 and the CDQ furnace shell 11 is divided into complete The upper and lower two-layer air chambers 8 and 9 are isolated, and the bottom of the lower cone bucket 2 is provided with a coke segregation regulating rod; as figure 2 As shown, the upper air chamber 8 is divided into a plurality of independent upper air chambers by the upper air chamber dividing pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com