New energy automobile double-motor drive axle

A new energy vehicle, dual-motor technology, applied in axles, wheels, motion deposition, etc., can solve problems such as poor ride comfort and handling stability, constraints on vehicle load and power, and large chassis curb weight, etc., to achieve The effect of reducing the unsprung mass, facilitating space layout, reducing self-weight and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

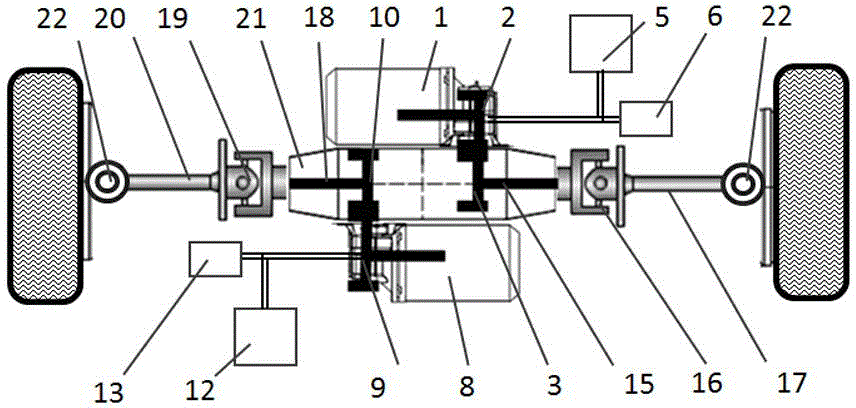

[0024] The double-motor drive axle can be divided into two structural forms: the integral bridge type double-motor drive axle and the disconnected double-motor drive axle.

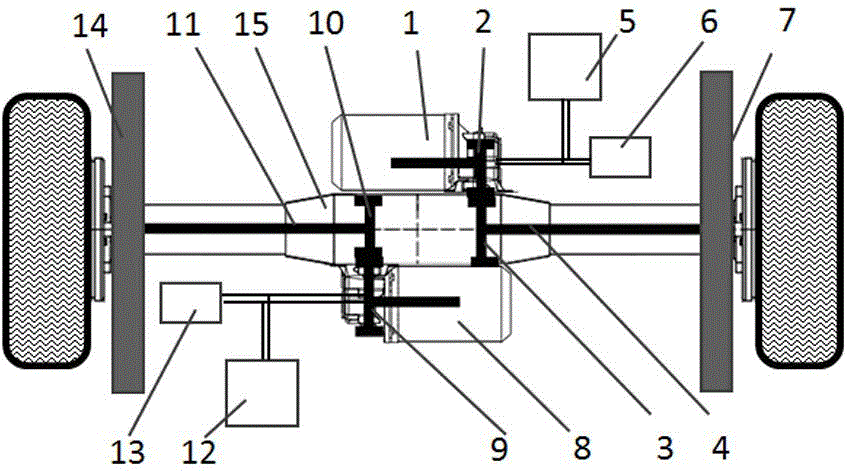

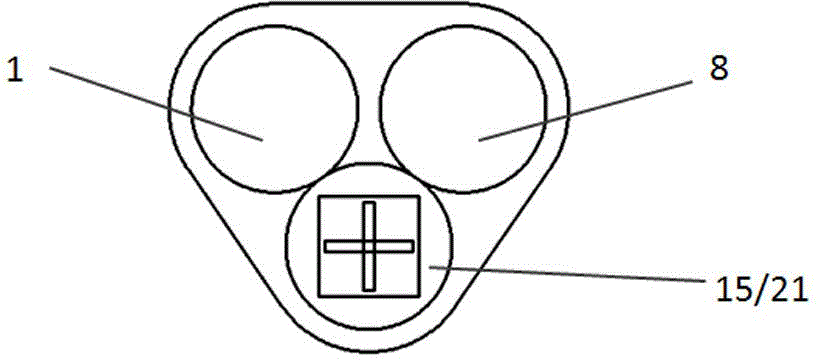

[0025] Such as figure 1 As shown, when an integral bridge-type double-motor drive axle structure is adopted, the double-motor drive axle includes a first motor 1, a reduction gear 2 at the first motor end, a reduction gear 3 at the first half-shaft end, a first half-shaft 4, First battery pack 5, first controller 6, right leaf spring 7, second motor 8, second motor end reduction gear 9, second half shaft end reduction gear 10, second half shaft 11, second battery pack 12 , the second controller 13, the left leaf spring 14, the axle housing 15; the output shaft of the first motor 1 is connected to the first motor end reduction gear 2, and the first motor end reduction gear 2 is connected to the first half shaft end reduction gear 3 meshing, the first half-shaft end reduction gear 3 is fixedly connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com