Variable-stiffness continuous type mechanism based on air pressure locking principle

A continuous, variable stiffness technology, used in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as insufficient response speed and insufficient variable stiffness, and achieve a high degree of flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the present invention will be further described:

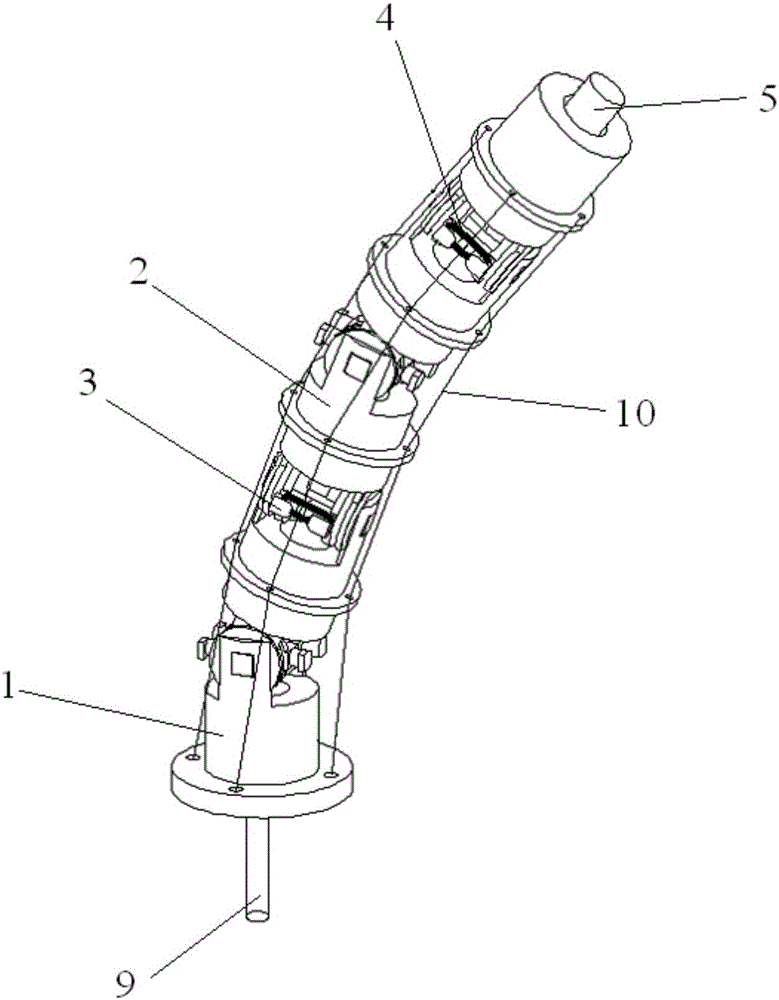

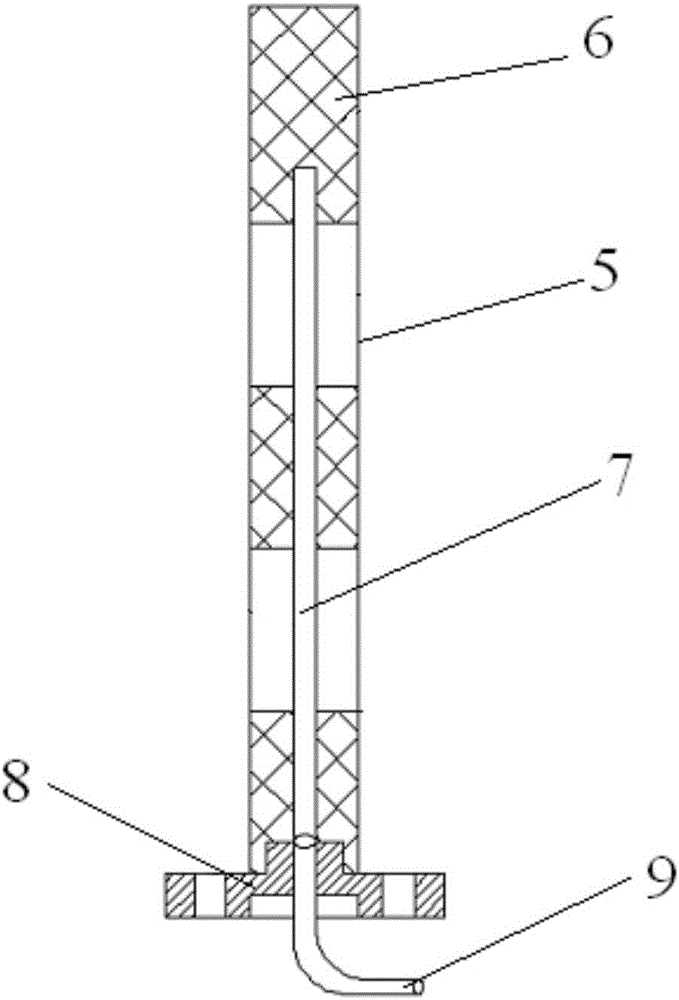

[0024] Such as Figure 1 to Figure 4 As shown, a continuous mechanism with variable stiffness based on the principle of pneumatic locking is composed of three parts: the continuous mechanism, the state conversion device and the pose control system. The direction is bent; the state conversion device enables the continuous mechanism to realize the conversion between rigid and flexible states through the air pressure locking and elastic release mechanism; the posture control system is used to control the bending degree of the continuous mechanism in different directions.

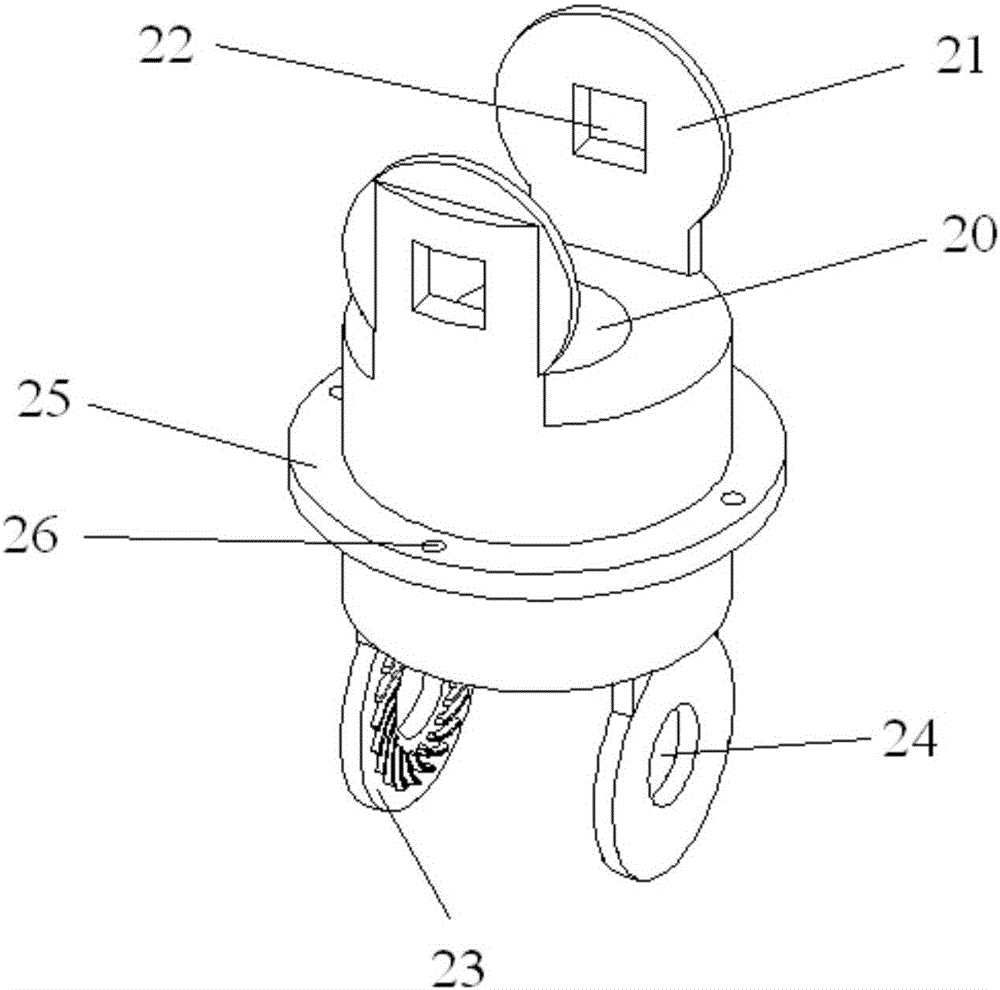

[0025] In this embodiment, the continuous mechanism consists of a base 1 and four joints 2 connected in series. A hollow structure 20 is provided in the middle of the joint 2. A connecting plate 21 with a square shaft hole 22 is provided at one end of the joint 2. The other end There is a first friction di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com