Reinforcement method for three-dimensional shaped object

A three-dimensional modeling and composition technology, which is applied in chemical instruments and methods, additive processing of mixtures of solid materials and liquid materials, and additive processing, and can solve problems such as reinforcement and poor machinability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

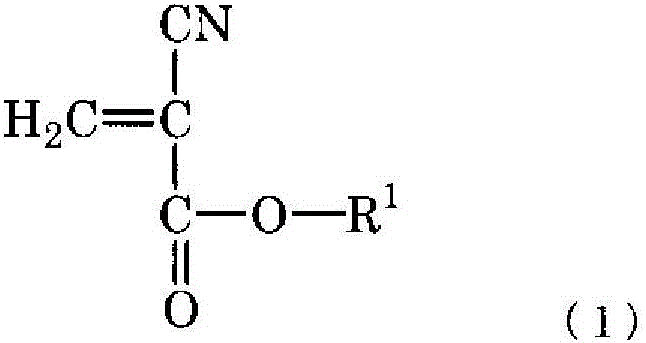

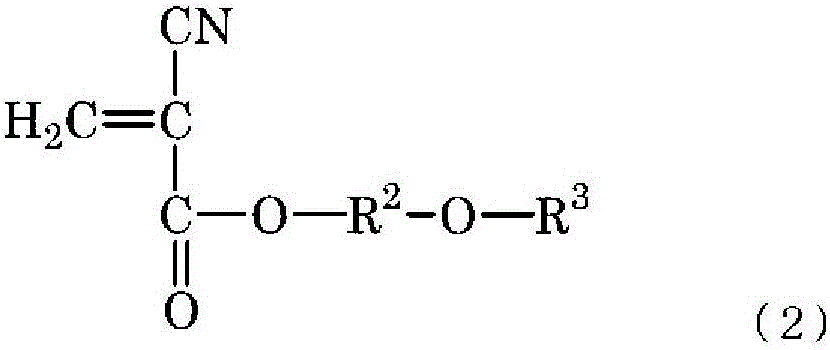

Method used

Image

Examples

Embodiment 1

[0093] Add 40 ppm of sulfur dioxide and 1000 ppm of hydroquinone to 2-ethoxyethyl cyanoacrylate (100 parts by mass of 2-ethoxyethyl cyanoacrylate), and stir at room temperature to obtain a combination for impregnation. things. The evaluation results are shown in Table 1.

Embodiment 2~7 and comparative example 1~6

[0095] The dipping compositions described in Table 1 were produced and evaluated. The thickeners described in Table 1 used the following ones.

[0096] ・Polymethyl methacrylate: manufactured by Evonik Japan Co., Ltd., trade name "DEGALAN", weight average molecular weight 300,000

[0097]

[0098] As shown in Table 1, the dipping compositions obtained in Examples 1 to 7 had no practical problems in all of the reinforcing effect, machinability, and whitening phenomenon. On the other hand, since the dipping compositions of Comparative Examples 1, 3, and 4 did not contain the 2-cyanoacrylate specified in the present invention, the whitening of the molded object was increased, resulting in poor appearance. In addition, although Comparative Examples 2 and 5 contained the 2-cyanoacrylate specified in the present invention, since the Shore hardness D of the cured product was higher than the range specified in the present invention, the machinability was poor. In addition, in Comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com