Electronic device

A technology for electronic equipment and circuit boards, applied in the electronic field, can solve problems such as high failure rate of electronic equipment components, affect the overall performance of electronic equipment, and small heat dissipation area, reduce the probability of failure, improve heat dissipation efficiency, and expand heat dissipation area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

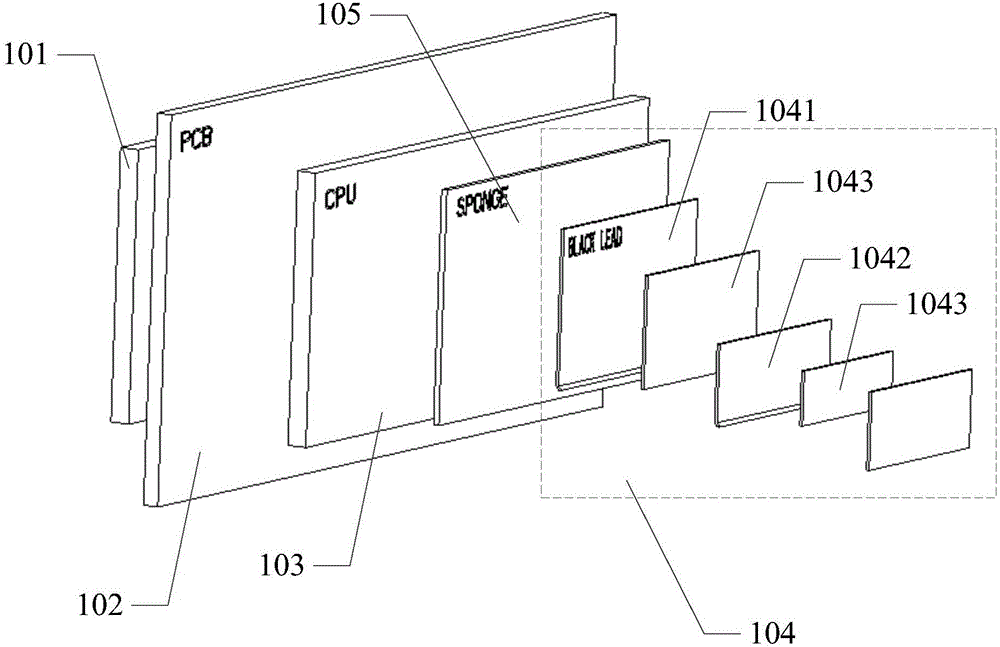

[0037] Please refer to figure 1 , Embodiment 1 of the present application provides an electronic device, including:

[0038] A display screen 101, where the surface of the display screen 101 is the first surface of the electronic device;

[0039] circuit board 102;

[0040] The heating element 103 is arranged on the circuit board 102;

[0041] Back shell, an accommodating space for accommodating the circuit board 102 and the heating element 103 is formed between the back shell and the display screen 101, and the surface of the back shell is the second surface of the electronic device. surface;

[0042] The heat dissipation structure 104 is arranged in the area corresponding to the heating element 103 in the accommodating space, and along the first direction from the front first surface to the second surface, the heat dissipation structure 104 includes at least two layers of heat dissipation layer, along the first direction, the heat dissipation area of the heat generated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com