Photoelectric component transfer method

A technology for optoelectronic components and transfer methods, which is applied to electrical components, electrical solid-state devices, circuits, etc., and can solve the problems of different lattice constants of the light-emitting layer, low conversion efficiency of color transfer materials, coating uniformity, and difficulty in growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

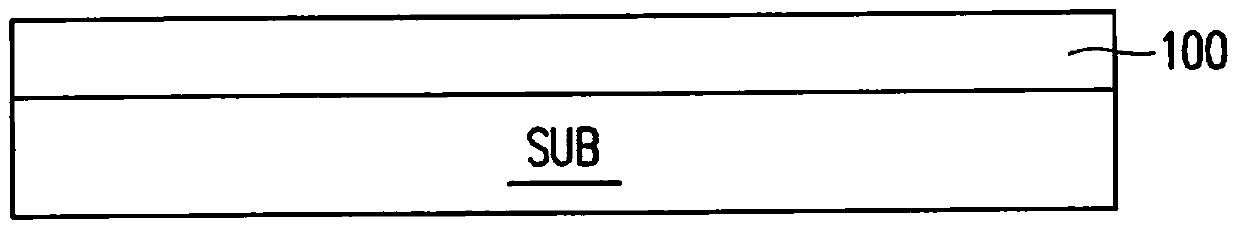

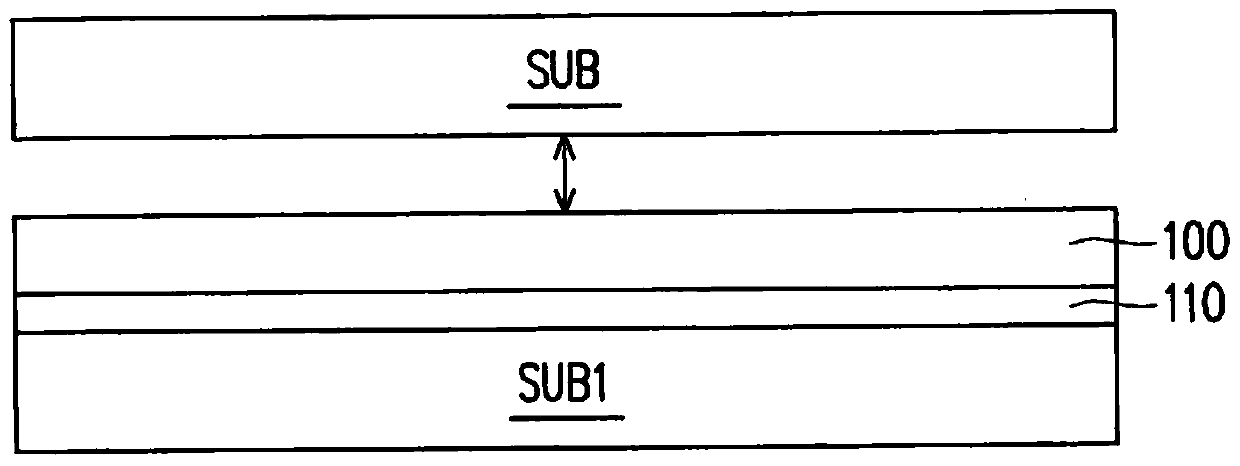

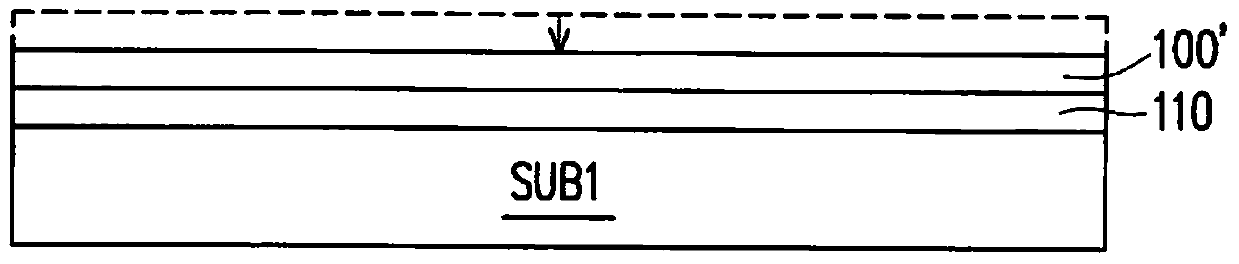

[0034] Figure 1A to Figure 1L It is a schematic flow chart of the photoelectric element transfer method according to the first embodiment of the present invention.

[0035] Please refer to Figure 1A to Figure 1E , firstly, a plurality of photoelectric elements PD arranged in an array are formed on a first substrate SUB1, wherein a sacrificial pattern SC is respectively formed on each photoelectric element PD, such as Figure 1E shown. In this embodiment, the plurality of photoelectric elements PD formed on the same first substrate SUB1 are, for example, light-emitting diode chips (LEDchips) capable of emitting the same color light or photo-sensing chips (photo-sensing chips) with the same photosensitive characteristics. ). For example, the photoelectric element PD can be a red LED chip, a green LED chip, a blue LED chip or a light sensing chip suitable for sensing a specific wavelength. In addition, electrodes (not shown) have been formed on each photoelectric element PD....

no. 2 example

[0054] Figure 2A to Figure 2I It is a schematic flow chart of the photoelectric element transfer method according to the second embodiment of the present invention.

[0055] Please refer to Figure 2A to Figure 2E A plurality of photoelectric elements PD arranged in an array are formed on the first substrate SUB1, wherein a first sacrificial pattern SC1 is respectively formed on each photoelectric element PD. Due to the formation method of the photoelectric element PD and the first sacrificial pattern SC1 and Figure 1A to Figure 1E , Figure 1E 'as well as Figure 1E " is similar, so it will not be repeated here. It should be noted that in this embodiment, the fabrication of the first sacrificial pattern SC1 can be omitted. In other words, the fabrication of the first sacrificial pattern SC1 is not necessary.

[0056] Then please refer to Figure 2F , forming a magnetic material layer M on the first sacrificial pattern SC1, so that the photoelectric element PD is covere...

no. 3 example

[0064] Figure 3A to Figure 3I It is a schematic flow chart of the photoelectric element transfer method according to the first embodiment of the present invention.

[0065] Please refer to Figure 3A to Figure 3E First, a plurality of photoelectric elements PD arranged in an array are formed on a first substrate SUB1, wherein a first sacrificial pattern SC1 and a second sacrificial pattern SC2 are respectively formed on each photoelectric element PD, and the first sacrificial pattern SC1 covers the photoelectric elements PD. On the element PD, and the second sacrificial pattern SC2 is located between the photoelectric element PD and the first substrate, and the photoelectric element PD is sandwiched between the first sacrificial pattern SC1 and the second sacrificial pattern SC2, as Figure 3E shown. In this embodiment, the plurality of photoelectric elements PD formed on the same first substrate SUB1 are, for example, light-emitting diode chips (LEDchips) capable of emitti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com