A rack that can quickly stack building turnover materials neatly

A fast and stacking technology, applied in the field of appliances, can solve the problems of slow material turnover on site, great influence on construction progress, and narrow construction site, so as to save materials, reduce the number of entry into the site, and speed up transshipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

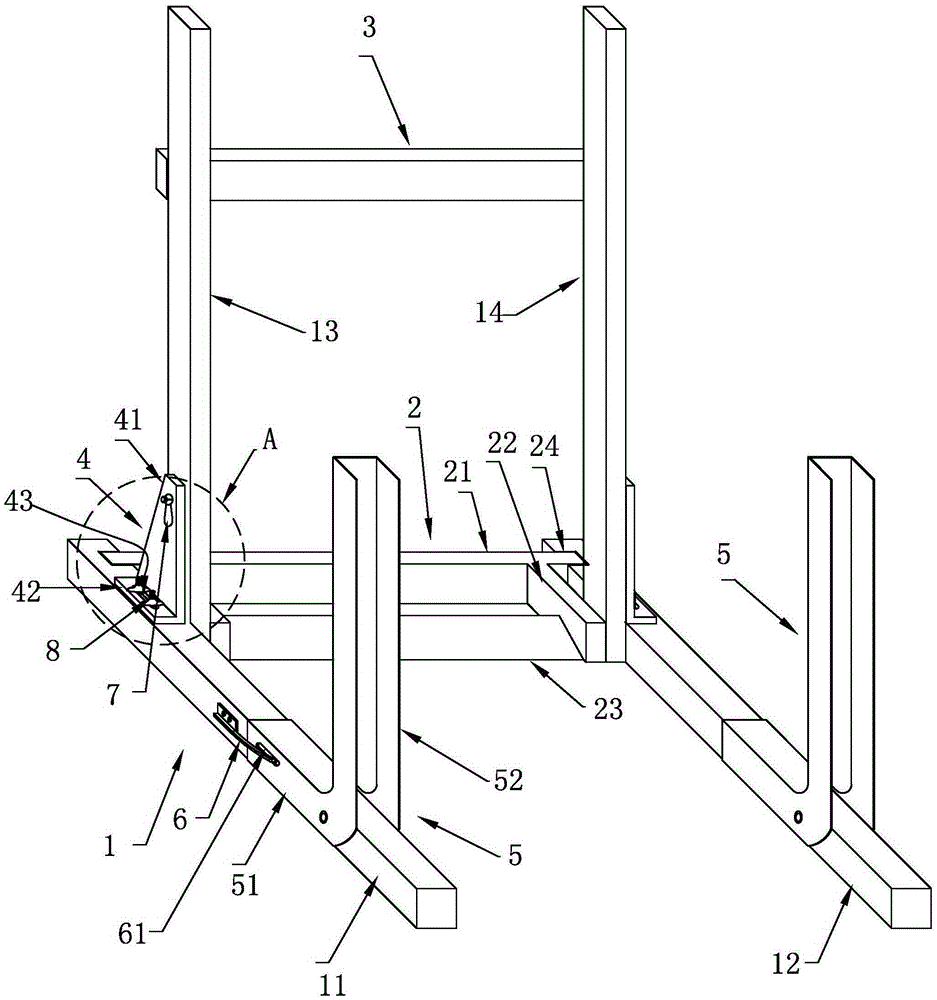

[0048] Such as figure 1 , 2 As shown, the left pillar 13 and the right pillar 14 of this embodiment are linear pillars parallel to each other. This structure is simple to manufacture and firm in structure, and is suitable for larger spaces.

Embodiment 2

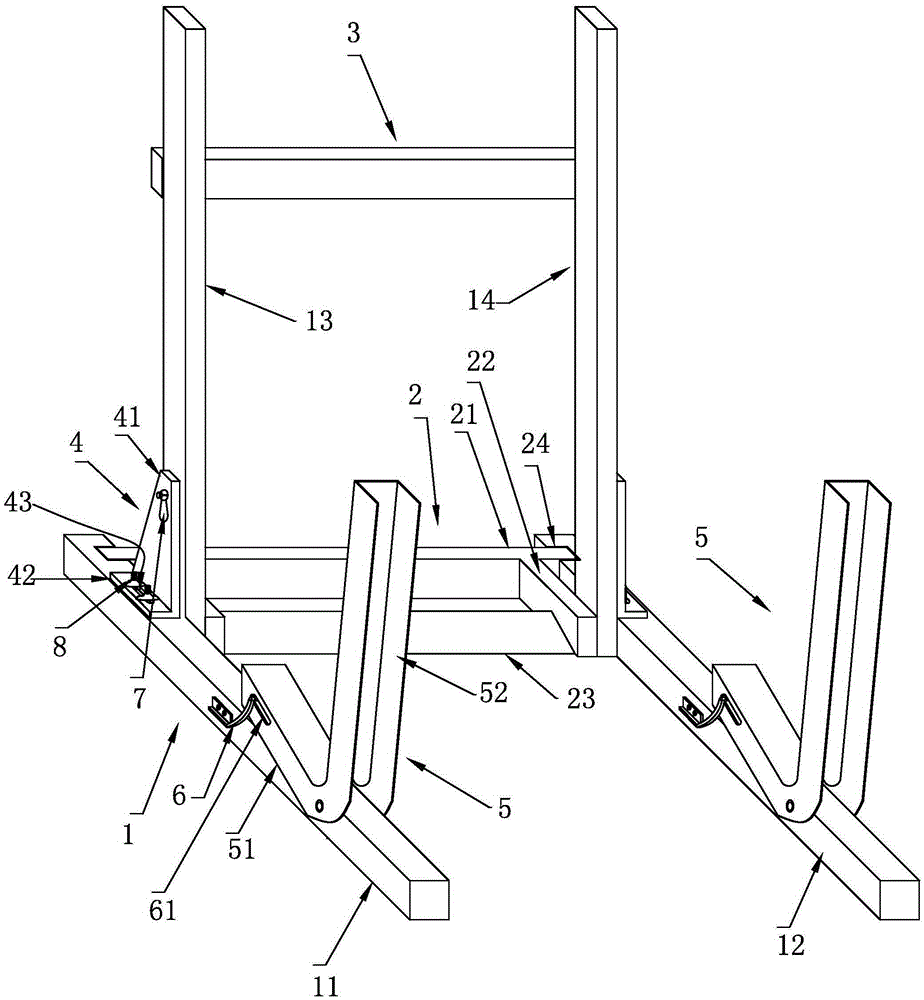

[0050] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the lower ends of the left pillar 13 and the right pillar 14 are parallel to each other, and the upper ends are close or cross-connected. This structure is suitable for places with less space above.

Embodiment 3

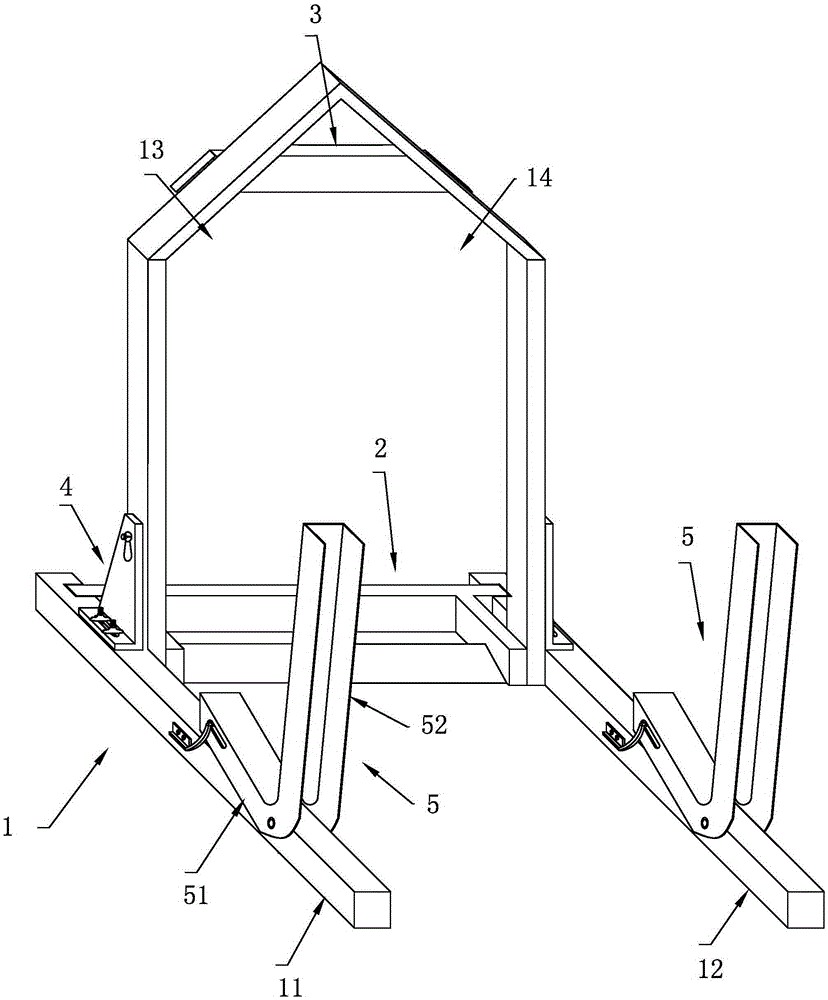

[0052] Such as Figure 4 As shown, the difference between this embodiment and embodiment 1 or embodiment 2 is only that the shapes of its left pillar 13, right pillar 14 and corresponding stop rod 52 are different. In this embodiment, the left pillar 13, right pillar 14, corresponding The longitudinal cross-sectional shape of the space surrounded by the support and the corresponding retaining rod 52 is oblate, and this structure is applicable to places where this shape is required when stacked revolving materials 9 are stored.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com