High-precision stacking machine

A stacking machine, high-precision technology, applied in the direction of sustainable manufacturing/processing, electrochemical generators, electrical components, etc., can solve the problems of poor alignment and different alignment of battery pole pieces, and reduce the working efficiency of the stacking machine , to achieve the effect of increasing lamination efficiency, precise stacking, and accurate discharging position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to describe the technical content, structural features, and achieved effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

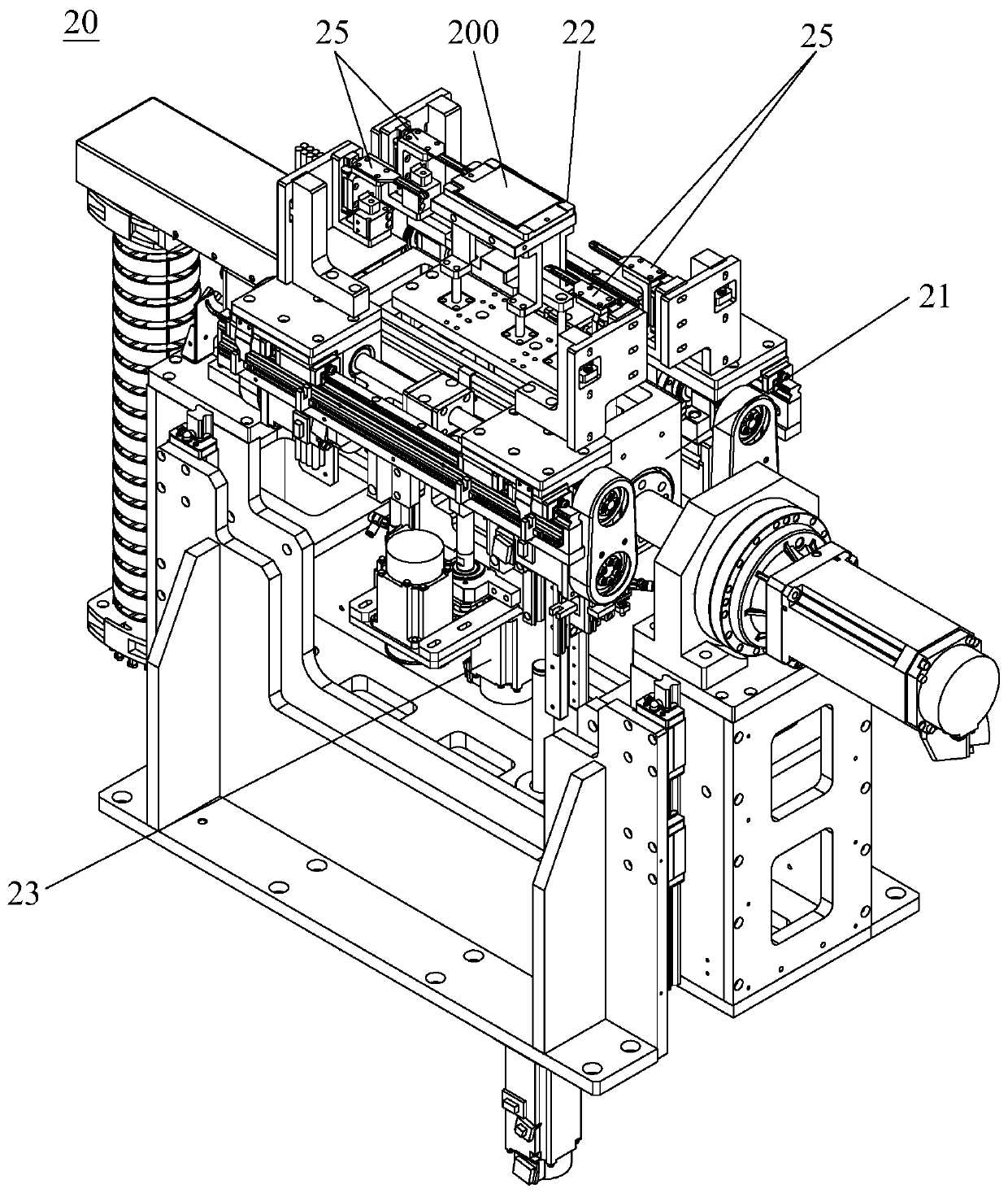

[0023] Please refer to Figure 1 to Figure 4 The high-precision stacking machine 100 of the present invention includes a frame 10, a stacking table 20 for stacking battery pole pieces 200, and a pick-and-place mechanism 30 for clamping battery pole pieces 200 and placing them on the stacking table 20, Wherein, the pick-and-place mechanism 30 and the stacking table 20 are both arranged on the frame 10 . The stacking platform 20 includes a platform 21 fixed on the frame 10, a workbench 22 for stacking and placing the battery pole pieces 200, and a driving device 23 connected to the workbench 22. The workbench 22 receives the pick-and-place mechanism 30 each time The placed battery pole pieces 200 are then driven by the driving device 23 to move d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com