Electronic cigarette casing inspection machine

A technology for electronic cigarettes and detection machines, which is applied in the direction of tobacco, conveyors, conveyor objects, etc., can solve the problems that the inspection of electronic cigarette cases takes a long time, etc., and achieve the realization of fully automatic detection process, high-efficiency detection, and fast cycle time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

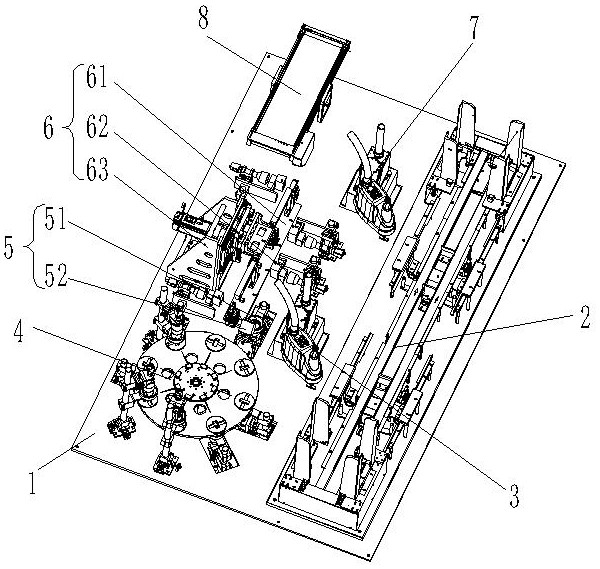

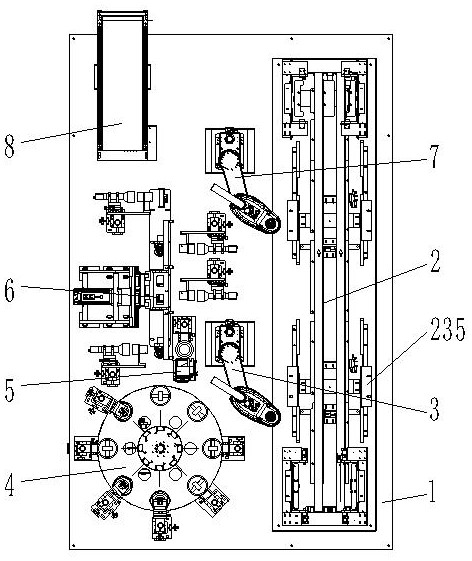

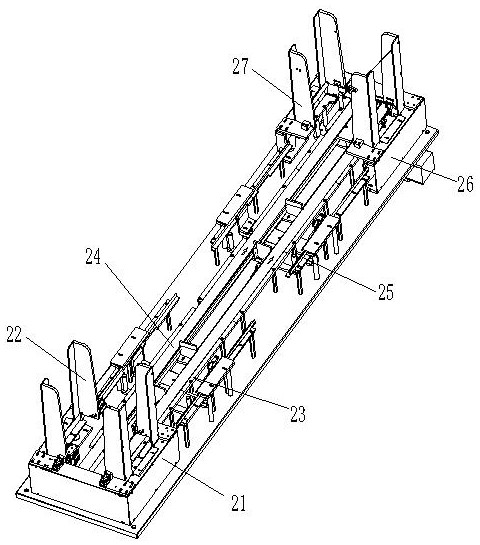

[0043] See Figure 1 to Figure 15 , the patent of the present invention has a working platform 1; the working platform 1 is provided with a feeding mechanism 2 for feeding the casing, a first detection mechanism 4 for detecting the upper end surface and the lower end surface of the casing, and a first detection mechanism 4 for detecting the upper end surface and the lower end surface of the casing. The upper casing is transferred to the first mechanical arm 3 on the first detection mechanism 4, the second detection mechanism 6 for detecting each side of the casing, the unloading mechanism 8 for unloading the unqualified casing, And the second mechanical arm 7 that can transfer the detected shell;

[0044] Both the first mechanical arm 3 and the second mechanical arm 7 are provided with transfer suction heads for shell transfer;

[0045] The second detection mechanism 6 includes a positioning assembly 61 for housing positioning, a photographing assembly 62 for photographing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com