Transfer device for cam shaft

A transfer device and camshaft technology, which is applied in metal processing and other directions, can solve the problems of low efficiency, time-consuming and laborious, etc., and achieve the effect of simple device structure, smooth transfer, and fast and efficient transfer of camshafts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

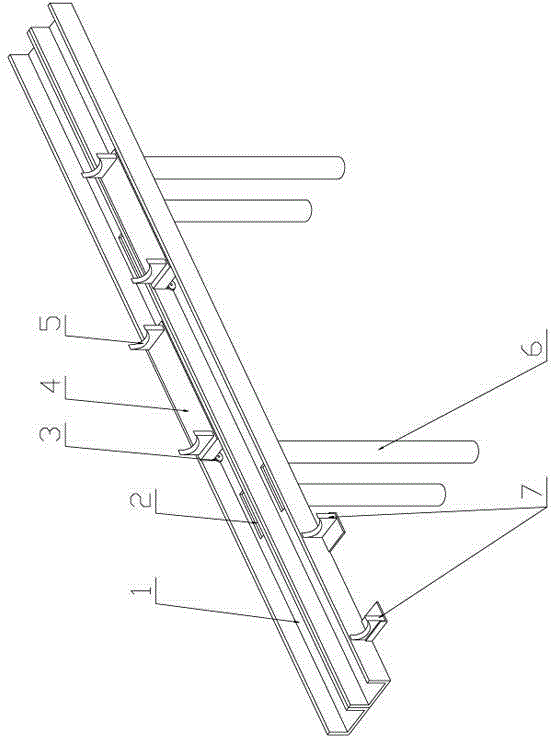

[0011] see figure 1 , the present invention is a camshaft transfer device, which has a leg 6, two guide rail grooves 1 with a rectangular cross section are arranged side by side on the leg, and 1-2 rolling camshaft rests are arranged in each guide rail groove The rolling camshaft shelf includes a bottom plate 4, two arc-shaped shelves 5 are arranged symmetrically on the left and right on the top of the bottom plate, and rolling wheels 3 are arranged on the bottom of the bottom plate. Match the settings.

[0012] In this embodiment, the groove bottom of each guide rail groove is provided with several dust removal ports 2, and the diameter of the dust removal ports is smaller than the installation width of the rolling wheels.

[0013] In this embodiment, several fixed camshaft shelves 7 are arranged on the outer wall of the guide rail groove.

[0014] When the device of the present invention is used, it is placed between two numerical control machine tools, and the worker only...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com