Integrated electromagnetic induction coil for wireless charging and preparation method thereof

A technology that integrates electromagnetic and induction coils. It is used in transformer/inductor coils/windings/connections, inductance/transformer/magnet manufacturing, transformer/inductor cores, etc. It can solve the problem that mass production cannot be realized and product performance cannot be guaranteed. , complex process routes, etc., to achieve the effect of improving wireless charging efficiency, low cost, and simple operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of the above-mentioned integrated electromagnetic induction coil for wireless charging comprises the following steps:

[0042] Step 1. Fixing: Fix the coil on the template.

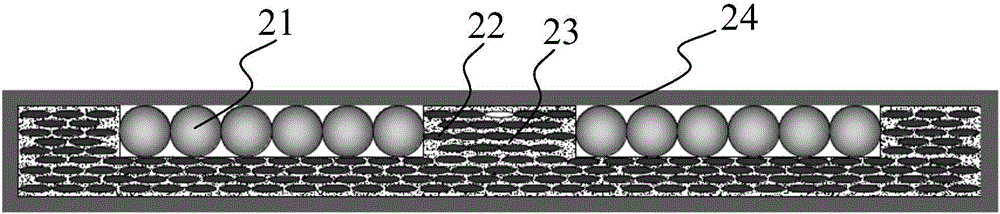

[0043] The template has the characteristics of high temperature resistance, it will not soften or deform during the drying process, and plastic products that can withstand high temperature can be used; the template is generally as figure 2 As shown, it has a three-dimensional shape and is provided with a cover. After fixing the coil, add scales, and finally cover the cover after being fixed and shaped; It is not removed afterwards, it is directly used as a protective part of the product.

[0044] Step 2, stacking: stacking amorphous or nanocrystalline scales in layers.

[0045] The specific operation is: sieve the amorphous or nanocrystalline scales, and scatter the center of the coil, the periphery of the coil, and the upper or lower surface of the coil accumulated on the...

Embodiment 1

[0068] The preparation method of the integrated electromagnetic induction coil for wireless charging in this embodiment includes the following steps:

[0069] (1) Heat treatment: Carry out heat treatment to the amorphous strip material, the temperature is 400 ℃, the time is 90 minutes, obtain the strip material after heat treatment; This amorphous strip material is made of Fe 78 Si 9 B 13 (at.%) alloy was formed with a thickness of 20 μm and a width of 142 mm.

[0070] (2) Crushing treatment: the heat-treated strip is crushed by a universal pulverizer, and then sieved by a sieve to form amorphous scales with a particle size of 0.3 mm.

[0071] (3) Fixing and stacking: the coil is pre-fixed on the bottom of the template, and then the amorphous scale is spread on the periphery and center of the coil in an overlapping manner to fill the shell as the template, and finally prepare a thickness of 2.5mm product; the thickness of this product is: the thickness of the product after ...

Embodiment 2

[0075] The preparation method of the integrated electromagnetic induction coil for wireless charging in this embodiment includes the following steps:

[0076] (1) Heat treatment: Carry out heat treatment to the amorphous strip material, the temperature is 400 ℃, the time is 90 minutes, obtain the strip material after heat treatment; This amorphous strip material is made of Fe 78 Si 9 B 13 (at.%) alloy was formed with a thickness of 20 μm and a width of 142 mm.

[0077] (2) Crushing treatment: the heat-treated strip is crushed by a universal pulverizer, and then sieved by a sieve to form amorphous scales with a particle size of 0.5 mm.

[0078] (3) Fixing and stacking: the coil is pre-fixed on the bottom of the template, and then the amorphous scale is spread on the periphery and center of the coil in an overlapping manner to fill the shell as the template, and finally prepare a thickness of 2.5mm product; the thickness of this product is: the thickness of the product after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com