Capacitive touch panel with single sensing layer

A capacitive touch and panel technology, which is applied in the direction of electrical digital data processing, instruments, digital data processing components, etc., can solve the problems of increasing the number of integrated circuit unit pins, increasing the size of IC, and increasing the cost of IC packaging. Achieve the effect of reducing IC size, reducing the number of contacts, and reducing packaging costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In the following, the technical means adopted by the present invention to achieve the intended purpose of the invention will be further described in conjunction with the accompanying drawings and the embodiments of the present invention.

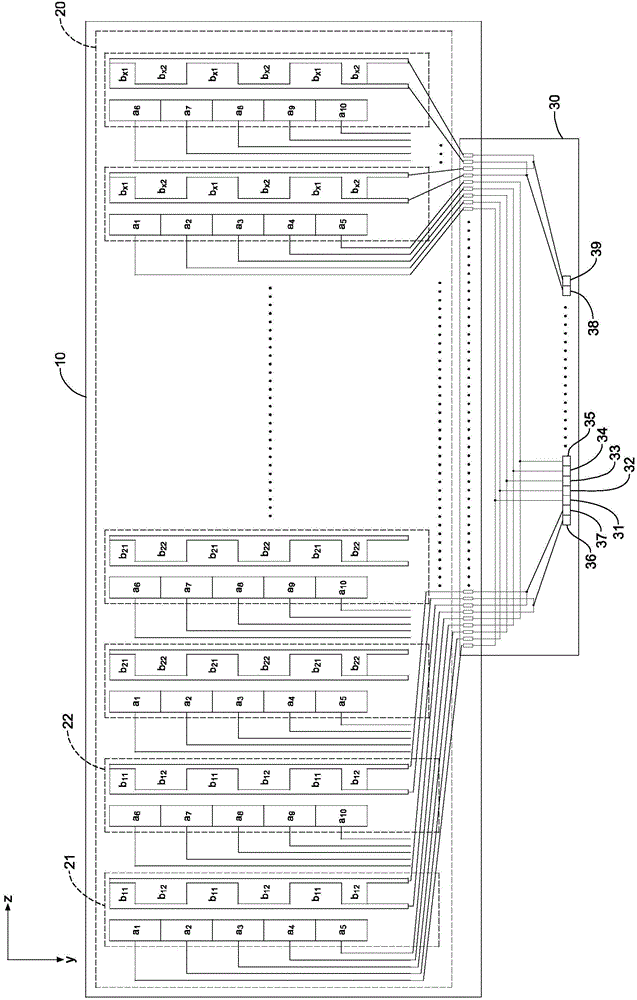

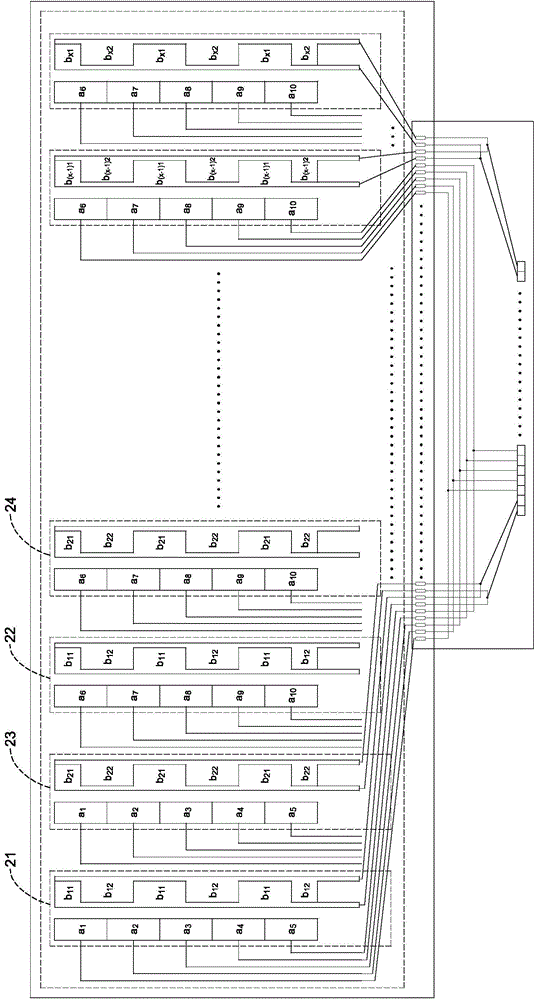

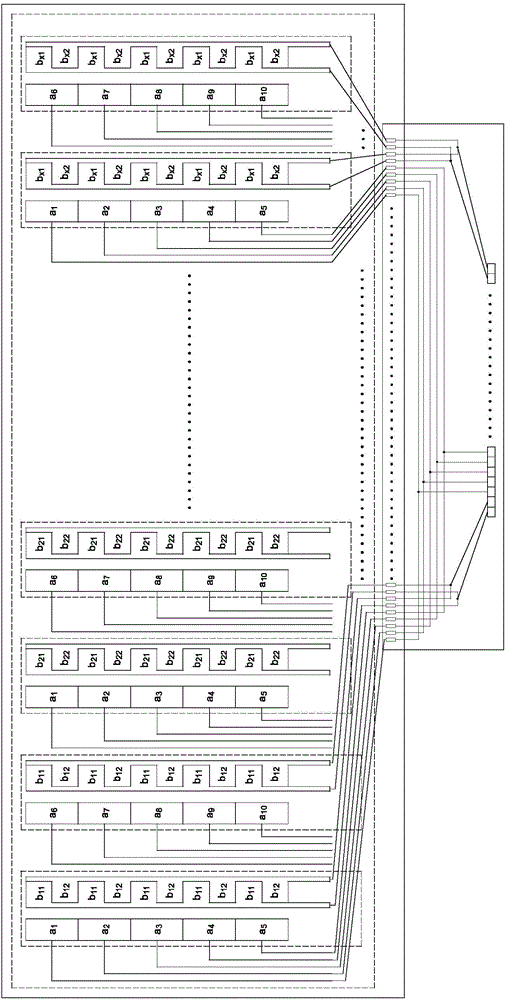

[0037] see figure 1 As shown, the single-layer capacitive touch panel of the present invention includes a substrate 10 and a sensing layer 20, the sensing layer 20 is arranged on one side surface of the substrate 10, and the sensing layer 20 includes n electrode groups, wherein the xth The electrode group includes i a-th electrodes and multiple b-th electrodes x electrode, the ath electrode includes the ath 1 to a i electrode, the b x The electrode contains multiple b x1 to b xj electrode to figure 1 Take the first group as an example, the ath electrodes are the ath 1 to a 10 electrode, b x The electrodes are b 11 electrode and b 12 electrode. Each electrode group includes a plurality of electrode groups, each electrode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com