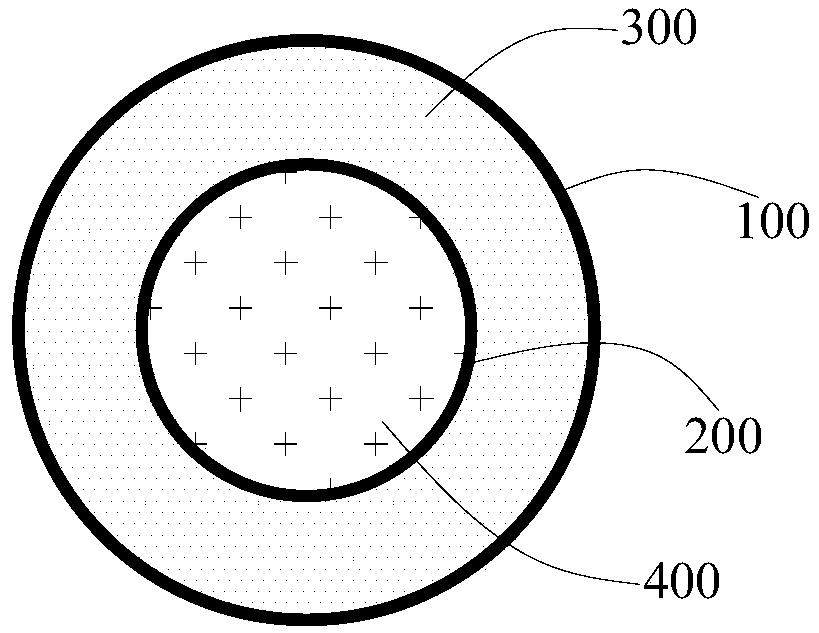

Frame sealant composition, box alignment method and display panel

A technology for display panel and frame sealant, applied in instruments, nonlinear optics, optics, etc., can solve the problems of charged particles polluting liquid crystal materials, low efficiency, and liquid crystal material decomposition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0036] In the present invention, there is no special limitation on the ratio of various components in the sealant composition. As a preferred embodiment of the present invention, each component of the sealant composition has the following mass ratio :

[0037] Frame sealant 99.5% to 95%;

[0038] Microspheres 0.5% to 5%.

[0039] When the two components in the frame sealant composition reach the above-mentioned ratio, it can not only ensure that the frame sealant is cured quickly, but also ensure that the two substrates set on the box can be fixed after the frame sealant is cured. stick together firmly.

[0040] In the present invention, there is no special requirement on the specific components of the frame sealant, for example, the frame sealant includes a high molecular weight epoxy resin and a polyamine crosslinking agent. This epoxy resin does not include groups with photochemical properties. Wherein, the molecular weight of the epoxy resin is between 2000 and 20000. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com