Test chamber capable of simulating mechanical properties of test pieces in high-temperature states and system with test chamber

A high-temperature state, test chamber technology, used in scientific instruments, strength characteristics, and application of stable tension/pressure to test material strength, etc. High performance, wide application range and accurate detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

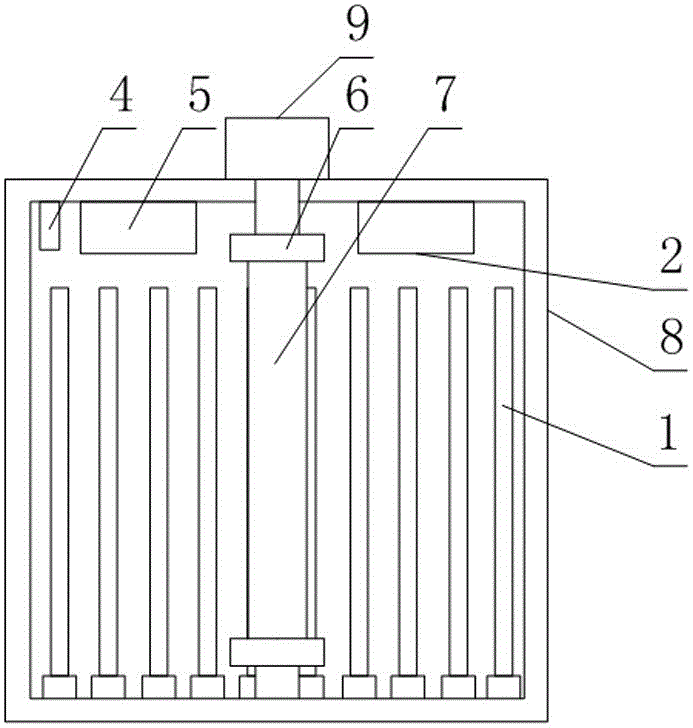

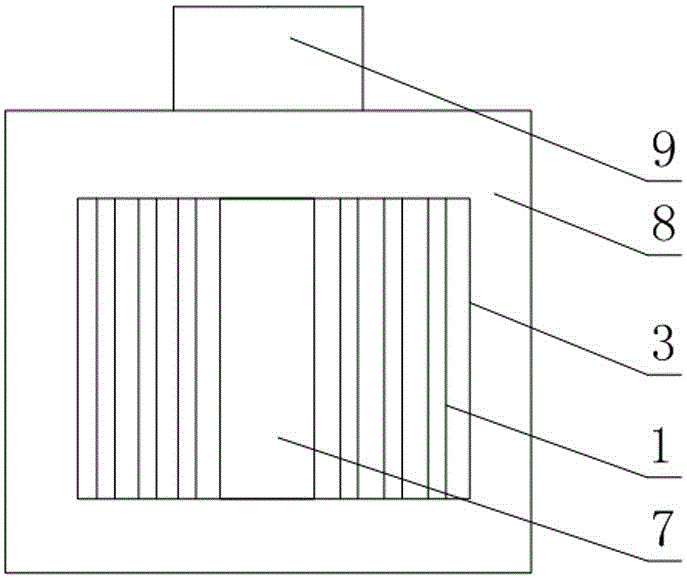

[0035] Such as Figure 1 to Figure 5 As shown, a test chamber capable of simulating the mechanical properties of a test piece under a high temperature state includes a case body 8 and a heating device 1 arranged in the case body 8. There are more than one heating device 1, and each heating device 1 is The positions in the box body 8 are all adjustable.

[0036] The box body 8 provided above is used to contain the test piece 7 that needs to carry out the mechanical performance simulation experiment under the high temperature state, and the heating device 1 arranged in the box body 8 is used to heat the environment in the box body 8, so as to be tested in the test. A high temperature environment is formed around the piece 7.

[0037] In this test box, there are more than one heating device 1, and the position of the heating device 1 in the box body 8 is adjustable, so as to adjust the mutual positions of the heating devices 1 according to specific simulation needs, so as to A ...

Embodiment 2

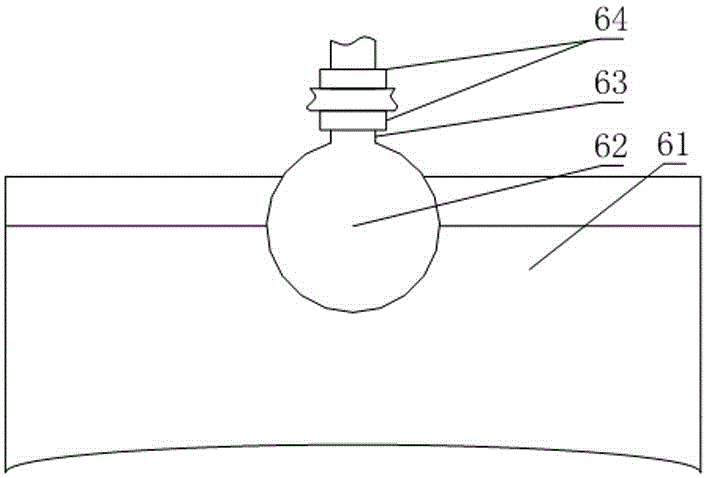

[0040] Such as Figure 1 to Figure 4 As shown, this embodiment is further limited on the basis of Embodiment 1: as a preferred implementation of the heating device 1, the heating device 1 is a resistance heating rod, and the wall of the box body 8 An annular hole is provided, and any one end of each heating device 1 is inserted into the annular hole, and the heating device 1 can slide in the annular hole, and each heating device 1 is also provided with a fixing device for realizing its fixed connection with the box body 8. device. In the above scheme, after the constraint of the fixing device on the heating device 1 is released, the heating device 1 can slide around the annular hole to linearly adjust the position of the heating device 1 in the annular hole. Restraining can make each heating device 1 maintain a fixed position in the box body 8 . Since the existing resistive heating rod generally emits visible light when it is working, the heating power of the resistive heati...

Embodiment 3

[0047] A system that can simulate the mechanical properties of specimens under high temperature conditions, such as Figure 1 to Figure 6 As shown, it includes a load loading device 9 , and also includes any test box solution provided by any one of the above embodiments. The test piece fixing end of the load loading device 9 is located inside the box body 8 .

[0048] The load loading device 9 provided above is used to apply the stress that needs to be simulated on the test piece 7, and the above load loading device 9 is used to load tensile stress, compressive stress, alternating stress, etc. on the test piece 7, such as using a pneumatic cylinder, hydraulic pressure, etc. The end of the piston rod of the cylinder acts on the test piece 7, and a load loading device 9 composed of a piezoelectric transducer and a displacement amplifier connected in series, and an ultrasonic signal generator as the piezoelectric transducer power input device is used. The above system can carry o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com