Stirring and heating type drum dryer

A drum dryer, stirring and heating technology, applied in non-progressive dryers, dryers, heating devices, etc., can solve the problem of uneven temperature between the outer cylinder and the inner cylinder, unfavorable energy saving, consumption reduction and emission reduction, heat conduction oil It is difficult to discharge in time and other problems to achieve the effect of improving heat exchange efficiency, simple structure and constant usage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand and implement the present invention, but the examples cited are not intended to limit the present invention.

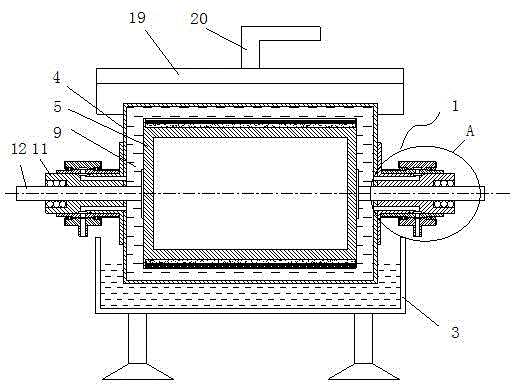

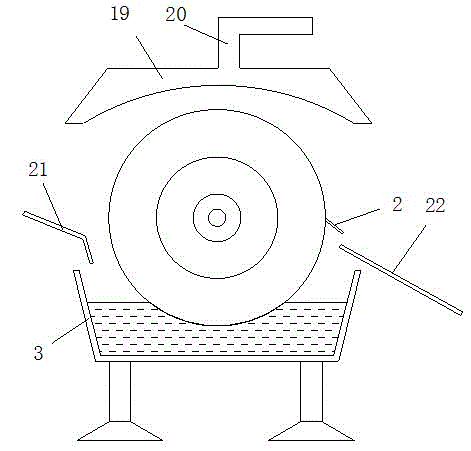

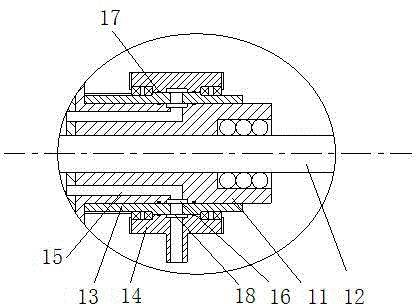

[0024] Such as figure 1 Shown is a schematic structural diagram of an embodiment of a stirring and heating drum dryer of the present invention. The stirring and heating drum dryer of this embodiment includes a drying drum 1, a scraper 2 and a material liquid pan 3. The drying drum 1 includes an outer cylinder 4, and the outer cylinder 4 is provided with an inner cylinder 5 coaxially rotating with it. The outer peripheral wall of the cylinder 5 is sequentially provided with a heat insulation layer 6, an electric heating layer 7 and a thin-walled heat-conducting layer 8 from the inside to the outside. A medium cavity 9 for storing thermal conductivity medium is provided between the outer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com