Heating boiler system with power generation function and working method of heating boiler system

A technology for heating boilers and working methods, which is applied to hot water central heating systems, heating systems, heating methods, etc., and can solve the problems of inability to realize energy ladder utilization, high-efficiency utilization, boilers that do not use the heating process, and cannot be effectively utilized. , to achieve the effect of comprehensive and efficient utilization, low cost and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

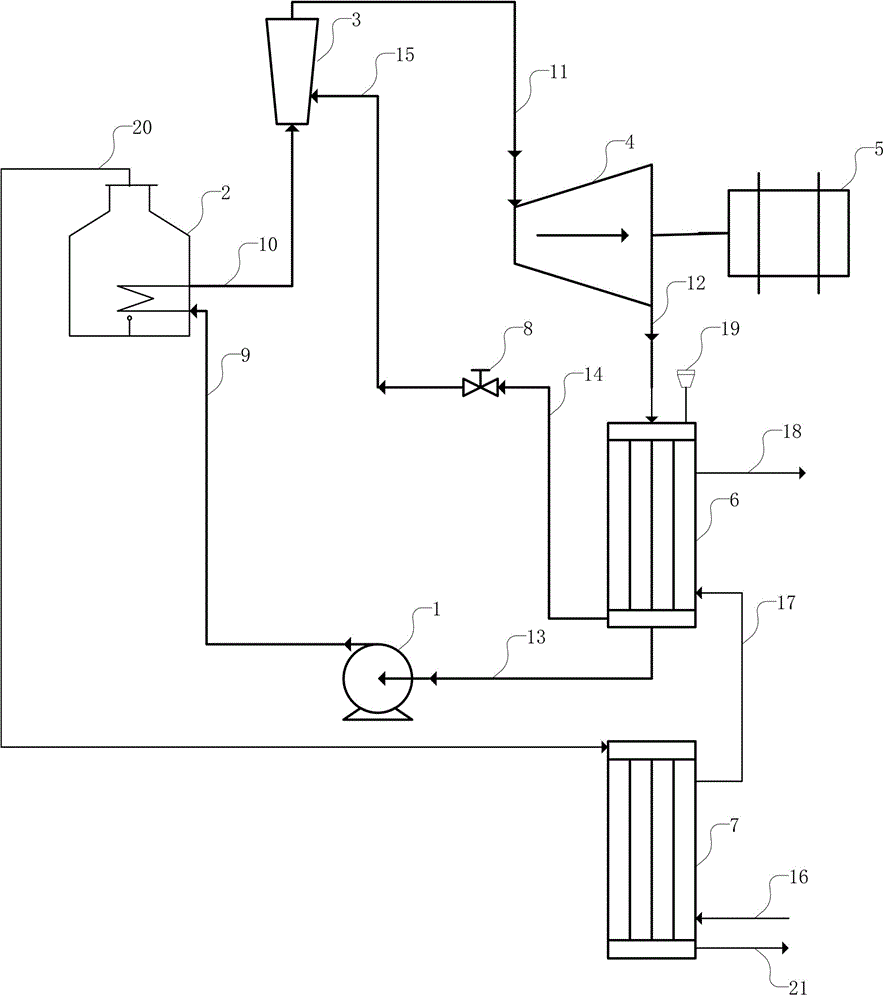

[0014] refer to figure 1 , the specific embodiment adopts the following technical solutions: a heating boiler system with power generation function, including a high-pressure water pump 1, a tube boiler 2, a jet pump 3, a steam turbine 4, a generator 5, a condensing heat exchanger 6, a flue gas return Heater 7, air return valve 8, boiler inlet pipe 9, high-pressure steam pipe 10, working steam pipe 11, exhaust steam pipe 12, condensed water pipe 13, uncondensed steam pipe 14, return and extraction steam pipe 15, heating return water pipe 16 , return water reheating pipe 17, heating outlet pipe 18, non-condensing steam exhaust head 19, boiler flue gas pipe 20 and flue gas exhaust pipe 21, the high-pressure water pump 1 is connected with the boiler water inlet pipe 9 of the tube boiler 2, and the pipe The high-pressure steam pipe 10 of the type boiler 2 is connected with the jet pump 3, the jet pump 3 is connected with the steam turbine 4 through the working steam pipe 11, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com