Tunnel supporting drilling robot

A robot and tunnel technology, which is applied in the direction of reciprocating drilling rigs, drilling equipment and methods, drilling equipment, etc., can solve the problems of complex design, inflexible drilling, and low control accuracy, and achieve high positioning accuracy, small footprint, Flexible drilling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

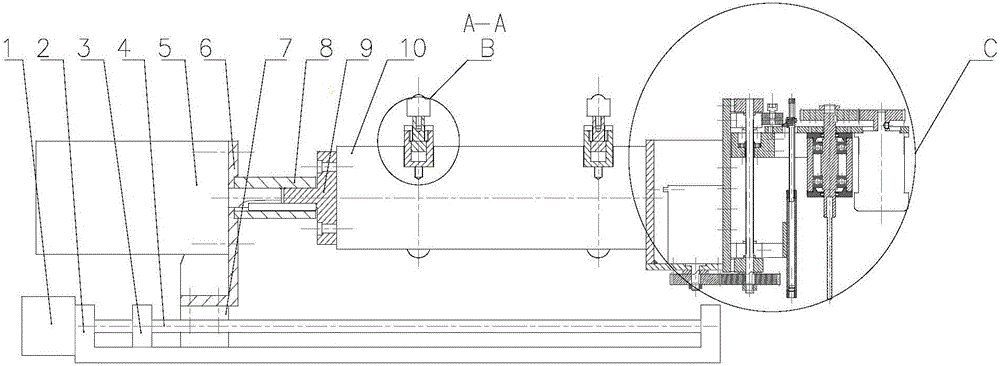

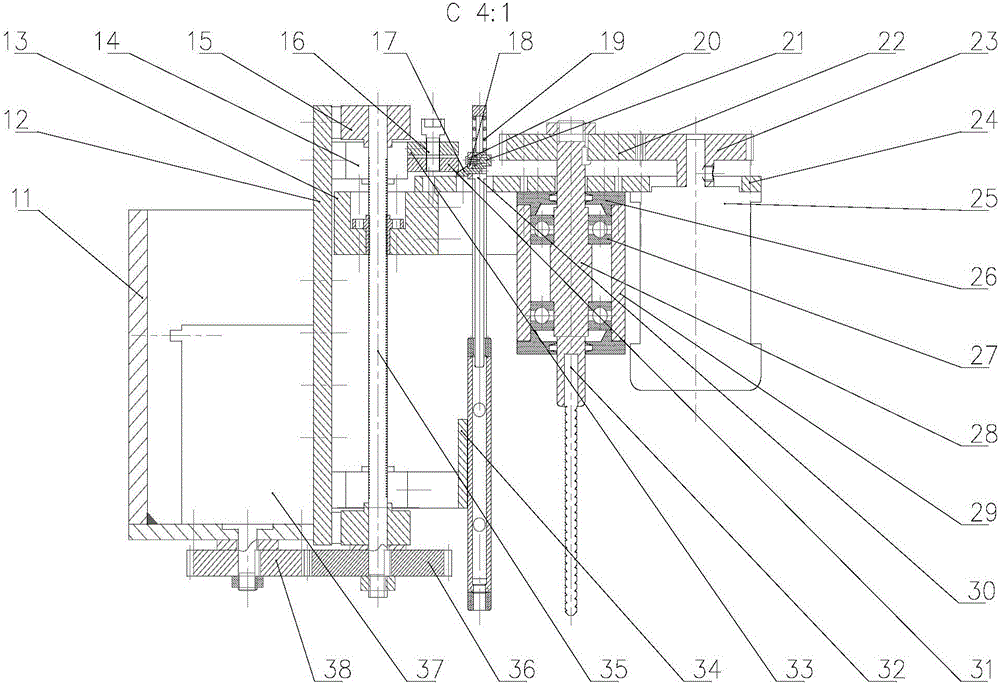

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

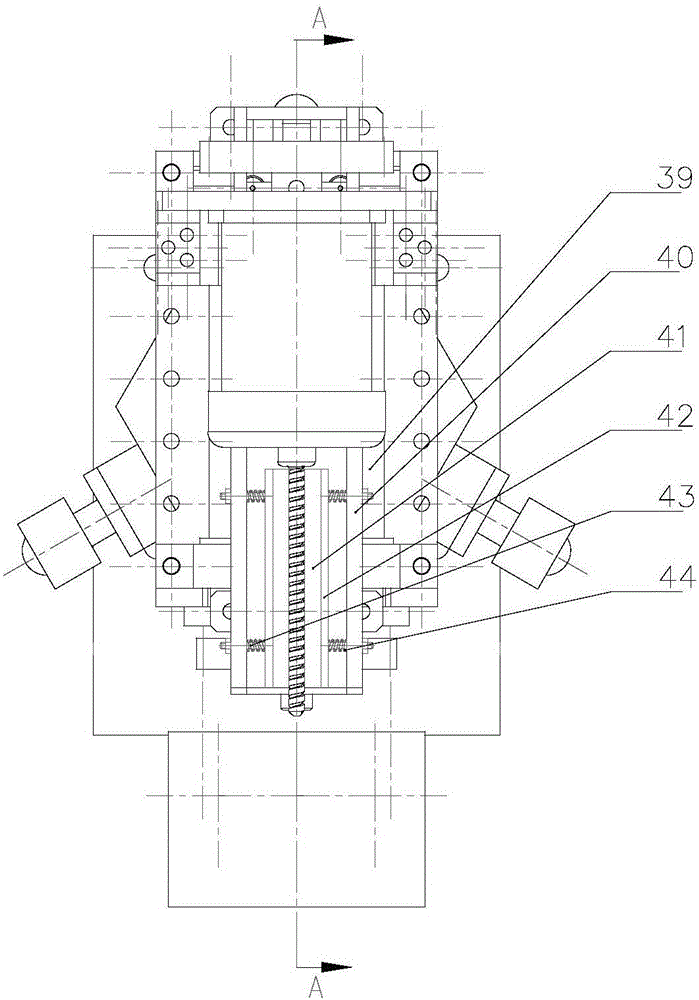

[0015] combine Figure 1 to Figure 6 , The main structure of the tunnel support drilling robot includes 1. Axial traveling motor, 2. Large sliding table, 3. Fixed slider, 4. Axial traveling screw, 5. Circumferential rotating motor, 6. Rotating motor connection Plate, 7, large slide, 8, coupling, 9, flange, 10, hexagonal shaft, 11, radial feed motor connection plate, 12, small slide, 13, small slide, 14, shaft seat , 15, lead screw bearing seat, 16, anchor rod push rod elastic fine-tuning bolt, 17, wedge block, 18, wedge block fixing plate, 19, spring, 20, wedge block spring, 21, guide cylinder rod, 22, drilling Transmission gear, 23, drilling transmission pinion, 24, connecting plate, 25, drill bit motor, 26, bearing cover, 27, bearing, 28, shaft, 29, cylinder, 30, anchor rod push rod, 31, moving Block, 32, drill bit, 33, fixed bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com