Pearl modified regenerated cellulose fiber and preparation method thereof

A technology of regenerated cellulose and modification, applied in the direction of artificial filaments made of viscose, can solve the problems of uneven distribution of pearl particles, great influence on spinning spinnability, uneven dispersion of pearl particles, etc. To achieve the effect of guaranteed spinning performance, high spinnability and long-lasting function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

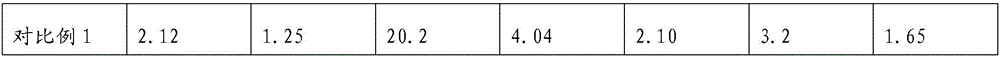

[0025] A pearl modified regenerated cellulose fiber, the modified regenerated cellulose fiber contains 2.5wt% pearl powder and 3.2wt% mica powder relative to the methyl fiber in the modified regenerated cellulose fiber.

Embodiment 2

[0027] A pearl modified regenerated cellulose fiber, the modified regenerated cellulose fiber contains 5.1wt% pearl powder and 1.8wt% mica powder relative to the methyl fiber in the modified regenerated cellulose fiber.

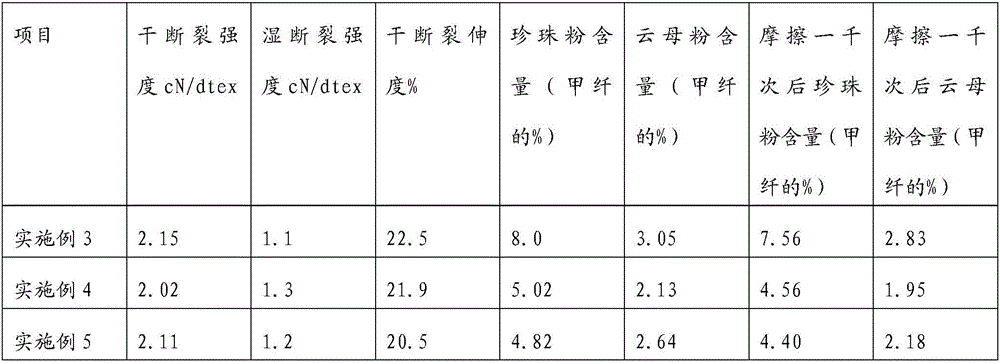

Embodiment 3

[0029] Honeycomb silica particles are used as the encapsulation material, and nano-scale pearl powder and nano-scale mica powder are evenly mixed, encapsulated in the honeycomb micropores of the honeycomb silica to prepare microcapsules, and after high-speed grinding, add The 4.5wt% caprylic capric triglyceride of described microcapsule was stirred and infiltrated for 5 minutes, was dissolved in water then, added the sodium dodecylbenzenesulfonate of 1.5wt% of described microcapsule, 1.5 wt% of described microcapsule wt% fatty alcohol ethoxylates, 3.0 wt% polyacrylamide of said microcapsules, 7.5 wt% trehalose of said microcapsules and 8.0 wt% cocamidopropyl beet of said microcapsules The alkali is mixed evenly to prepare a modified emulsion;

[0030] Using cellulose pulp to prepare spinning solution, fully mixing the modified emulsion with the spinning solution through a static or dynamic mixer to obtain a modified spinning solution, passing the modified spinning solution thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com