Durable blowpipe material

A durable and tube material technology, applied in the field of metal smelting and durable blow tube material, can solve the problems affecting the life of the blow tube steel shell, the influence of blast furnace intensified smelting operation, and the blow tube is prone to redness, so as to improve the density and thermal shock stability properties, high strength, and reduced hardening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

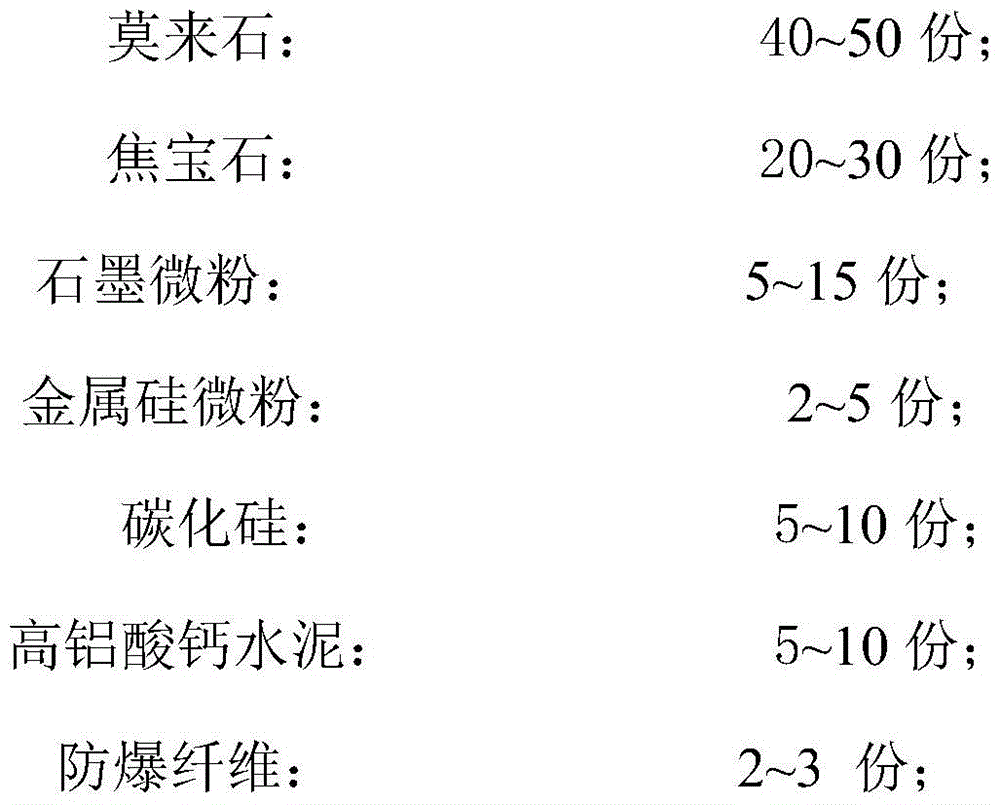

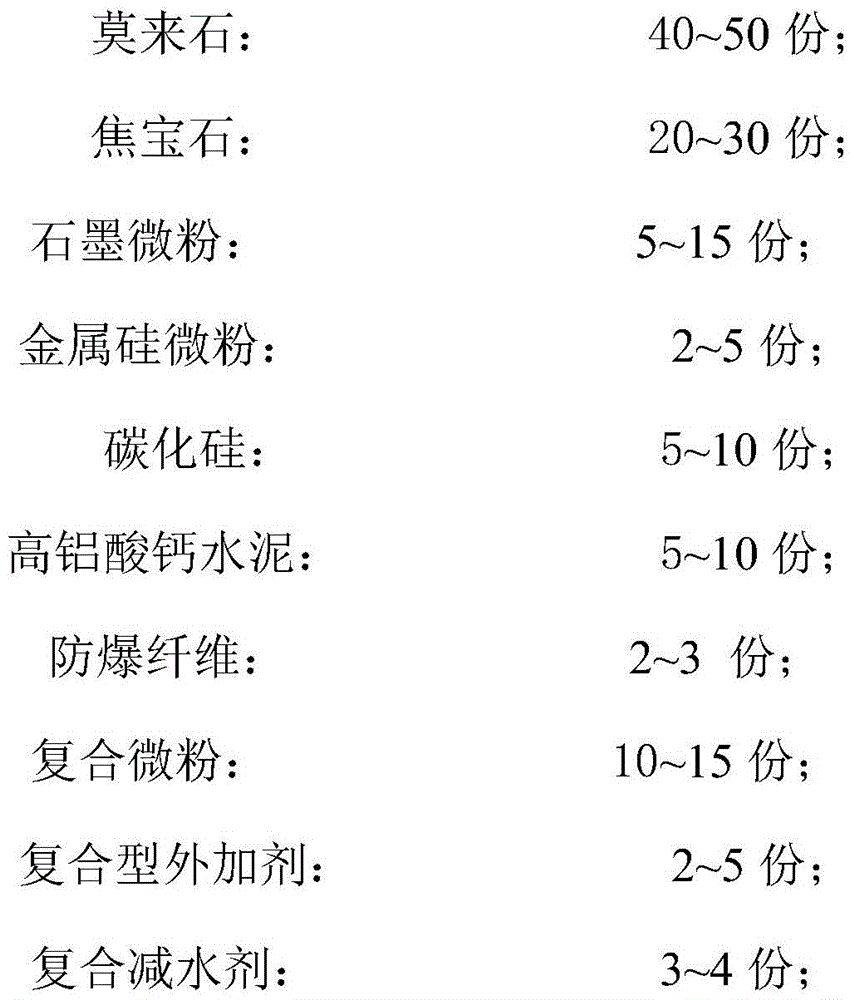

[0025] Example 1: mullite: 45 parts; coke gem: 25 parts; graphite powder: 15 parts; metal silicon powder: 5 parts; silicon carbide: 7 parts; calcium peraluminate cement: 10 parts; explosion-proof fiber: 2 parts ; Composite micropowder: 15 parts; Composite admixture: 5 parts; Composite water reducing agent: 3 parts.

Embodiment 2

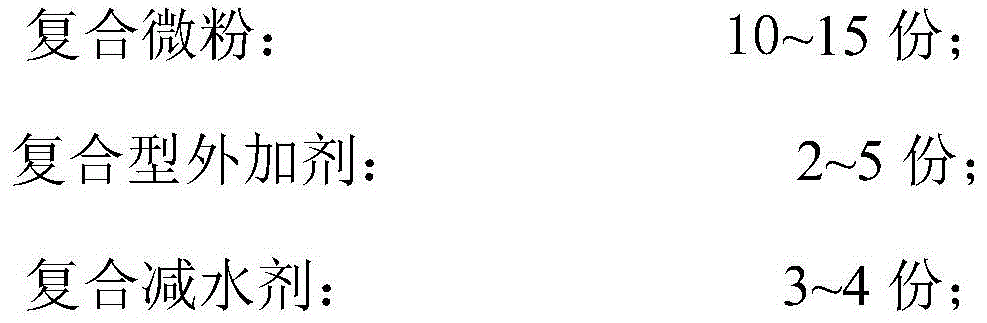

[0026] Example 2: mullite: 40 parts; coke gem: 30 parts; graphite powder: 10 parts; metal silicon powder: 5 parts; silicon carbide: 5 parts; calcium peraluminate cement: 10 parts; explosion-proof fiber: 2 parts ; Composite micropowder: 10 parts; Composite admixture: 3 parts; Composite water reducing agent: 4 parts.

Embodiment 3

[0027] Example 3: mullite: 50 parts; coke gem: 25 parts; graphite powder: 15 parts; metal silicon powder: 3 parts; silicon carbide: 8 parts; calcium peraluminate cement: 6 parts; explosion-proof fiber: 3 parts ; Composite micropowder: 12 parts; Composite admixture: 4 parts; Composite water reducing agent: 4 parts.

[0028] The present invention introduces carbon powder, silicon powder and composite additives with a particle size of 10um into the blow pipe material by improving the formula. The introduction of special carbon powder and silicon powder of about 10um produces SiC whiskers evenly distributed in the matrix and particle gaps during the firing process, filling the expansion of the material during the firing process, and SiC combined with the ceramic phase improves the density and density of the material. Thermal shock stability, while obtaining higher strength, reduces the probability of burn-through of the blowpipe during use. Composite sodium hexametaphosphate and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com