Non-steam autoclaved high performance concrete tube pile using calcium silicate hydrate seed powder as exciting agent, and preparation method of non-steam autoclaved high performance concrete tube pile

A technology of high-performance concrete and calcium silicate hydrate, which is applied in the direction of manufacturing tools, reinforced molding, ceramic molding machines, etc., can solve problems such as ineffective effects, achieve shortened production cycle, high strength in the later stage, good economic benefits and The effect of social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

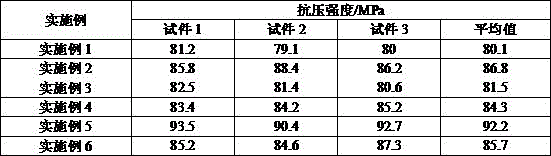

[0046] Example 1, a pressure-free steamed high-performance concrete pipe pile using calcium silicate hydrate seed powder as an activator, selects the bottom mold of a circular steel mold, and puts it into a pre-programmed steel cage; according to 42.5 grades Ordinary Portland cement 100, slag powder 25, calcium silicate hydrate seed powder 2, river sand 120, stone 225, water reducing agent 1.5, defoamer 0.05 weight ratio to weigh the material, according to 26% of the amount of cement Add water and stir for about 60s; add the stirred concrete into the above mold for centrifugal molding; stop for 3 hours after molding, and then perform normal pressure steam curing, the curing temperature is 90°C, and the steam curing time is 8 hours; use and obtain simultaneously with pipe piles The strength of the concrete specimens is tested, and the strength of the specimens is shown in Table 1. The strength of the specimens has reached C80, which means that the strength of the concrete pipe p...

Embodiment 2

[0047]Embodiment 2, a pressure-free steamed high-performance concrete pipe pile using calcium silicate hydrate seed powder as an activator, selects the bottom mold of a circular steel mold, and puts it into a pre-woven steel cage; according to 42.5 grades Ordinary Portland cement 100, slag powder 30, hydrated calcium silicate seed crystal powder 8, river sand 130, stone 215, water reducing agent 2.0, defoamer 0.20 Weigh the material by weight, according to 27% of the cement dosage Add water and stir for about 60s; add the stirred concrete into the above mold for centrifugal molding; stop for 3 hours after molding, and then perform normal pressure steam curing, the curing temperature is 90°C, and the steam curing time is 8 hours; use and obtain simultaneously with pipe piles The strength of the concrete specimens is tested, and the strength of the specimens is shown in Table 1. The strength of the specimens has reached C80, which means that the strength of the concrete pipe pile...

Embodiment 3

[0048] Embodiment 3, a pressure-free steamed high-performance concrete pipe pile using calcium silicate hydrate seed powder as an activator, selects the bottom mold of a circular steel mold, and puts it into a pre-woven steel cage; according to 42.5 grades Ordinary Portland cement 100, slag powder 40, calcium silicate hydrate seed powder 12, river sand 145, stone 200, water reducing agent 2.5, defoamer 0.50 weight ratio to weigh materials, according to 28% of cement consumption Add water and stir for about 60s; add the stirred concrete into the above mold for centrifugal molding; stop for 3 hours after molding, and then perform normal pressure steam curing, the curing temperature is 90°C, and the steam curing time is 8 hours; use and obtain simultaneously with pipe piles The strength of the concrete specimens is tested, and the strength of the specimens is shown in Table 1. The strength of the specimens has reached C80, which means that the strength of the concrete pipe piles h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com