An adsorption-membrane separation water treatment device and method enhanced by excess sludge

A technology for water treatment devices and excess sludge, applied in water/sludge/sewage treatment, water/sewage multi-stage treatment, chemical instruments and methods, etc., can solve the problem of difficult solid-liquid separation of adsorbents, high cost of adsorbent materials, Problems such as large footprint, to achieve the effect of improving application range and processing capacity, reducing secondary pollution, and saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

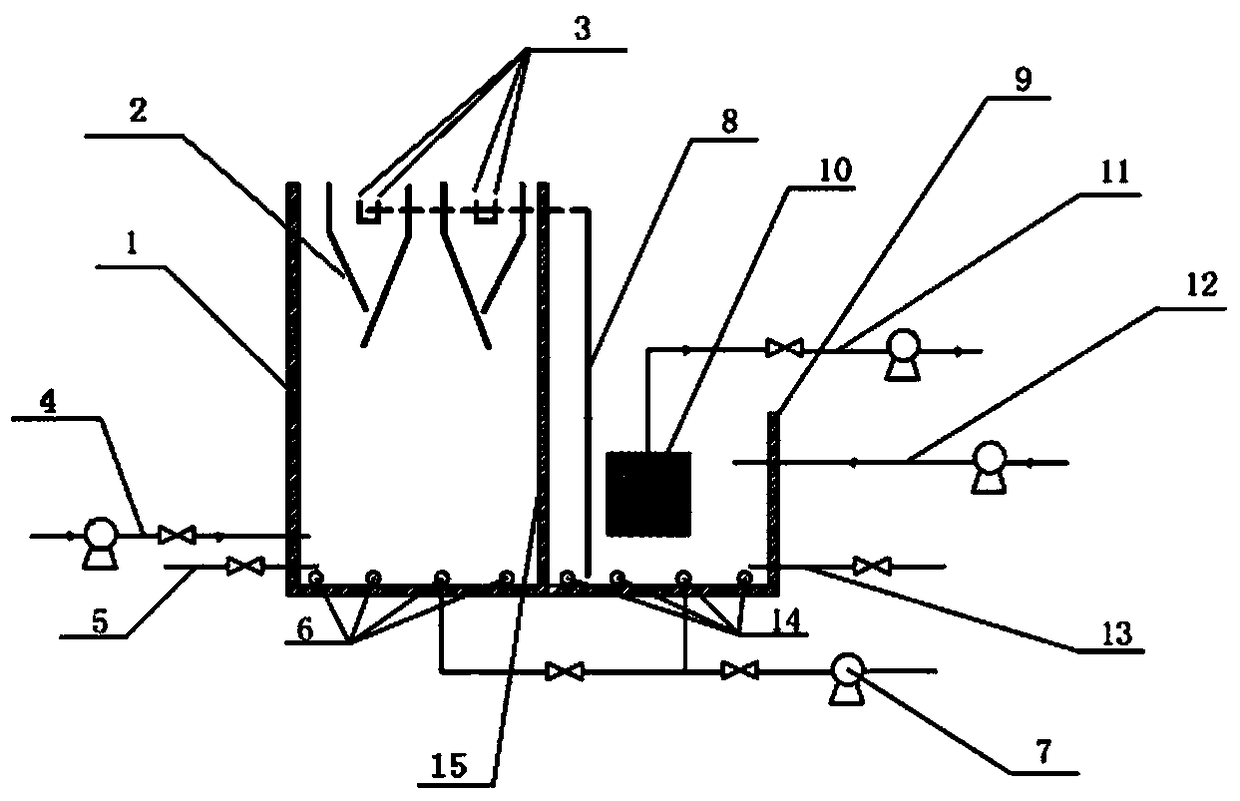

[0052] The various indicators of the biochemical tail water of a coal chemical industry wastewater are: chemical oxygen demand (COD Cr ) is 300mg / L-350mg / L, suspended solids (SS) is 100mg / L-120mg / L, turbidity is 45NTU-50NTU, the color is slightly yellow, and the water volume is 300m 3 / d.

[0053] Using the adsorption-membrane separation water treatment device and method for excess sludge enhancement of the present invention, the adsorbent used is activated coke (particle size 0.045mm-0.15mm), and the raw water is mixed with the raw water at a mass ratio of 500:1 and then passed from the bottom Upflow type adsorption tank, the effective water depth of the adsorption tank is 4m, the ascending flow rate is set to 2m / h, the air-water ratio is 15:1, and the coke is discharged through the discharge pipe to maintain the active coke concentration of 2g / L in the adsorption tank. After 2 hours of adsorption reaction, enter the top pre-sedimentation area for preliminary solid-liquid se...

Embodiment 2

[0056] The various indicators of wastewater from an enterprise in the printing and dyeing industrial park are: chemical oxygen demand (COD Cr ) is 1500mg / L-1750mg / L, suspended solids (SS) is 1800mg / L-2000mg / L, water volume is 1200m 3 / d, the effluent of the enterprise must meet the management standards of the park, and the location of the enterprise cannot build large-scale water treatment structures due to limited conditions.

[0057] Using the adsorption-membrane separation water treatment device and method strengthened by excess sludge of the present invention, the raw water and some activated carbon (particle size 0.075mm-0.15mm) are mixed at a mass ratio of 250:1 and then passed into the upflow adsorption tank from the lower part , the effective water depth of the adsorption tank is 6m, the aspect ratio is 6, the ascending flow rate is set to 3m / h, the air-water ratio is 30:1, and the activated carbon discharged through the discharge pipe keeps the concentration of activa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com