Lifting device and inverted installing method for reducing absorption tower

An absorption tower and inversion technology, which is applied in the field of inversion of variable diameter absorption towers, can solve the problems of variable diameter absorption towers such as complicated procedures, slow progress, and difficult control of installation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

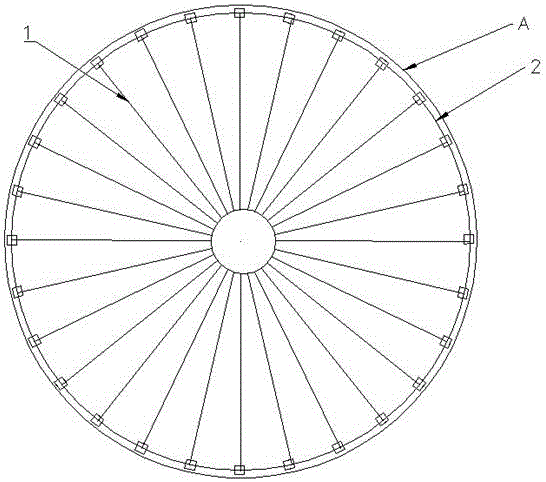

[0092] Attached below Figure 1 to Figure 10 Embodiments of the present invention are described in detail.

[0093] As shown in the figure, the lifting device includes a hydraulic lifting circular frame 1, an expansion ring 2 attached to the inner wall of the cylinder, and a door-shaped steel clip 3 for fixing the expansion ring. The door-shaped steel clip 3 is buckled on the expansion ring 2 and connected with The inner wall of the cylinder is welded and fixed, and the hydraulic lifting circular frame 1 includes hydraulic lifting frames 11 uniformly distributed on the inner side of the cylinder A along the circumference, a central steel pipe 12 arranged in the center of the cylinder A, and successively connected to the circumferential direction of each hydraulic lifting frame 11. Channel steel 13 and the radial channel steel 14 that is used to connect central steel pipe 12 and hydraulic lifting frame 11, hydraulic lifting frame 11 and central steel pipe 12 are all welded and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com