Drive sprockets for passenger conveyors

A technology of passenger conveying device and driving sprocket, which is applied in the direction of winch device, transportation and packaging, portable lifting device, etc. It can solve the problems of vibration damping pad installation error, inconsistent meshing height, large installation workload, etc., and achieve reduction Noise and vibration, reduction of meshing vibration, low installation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

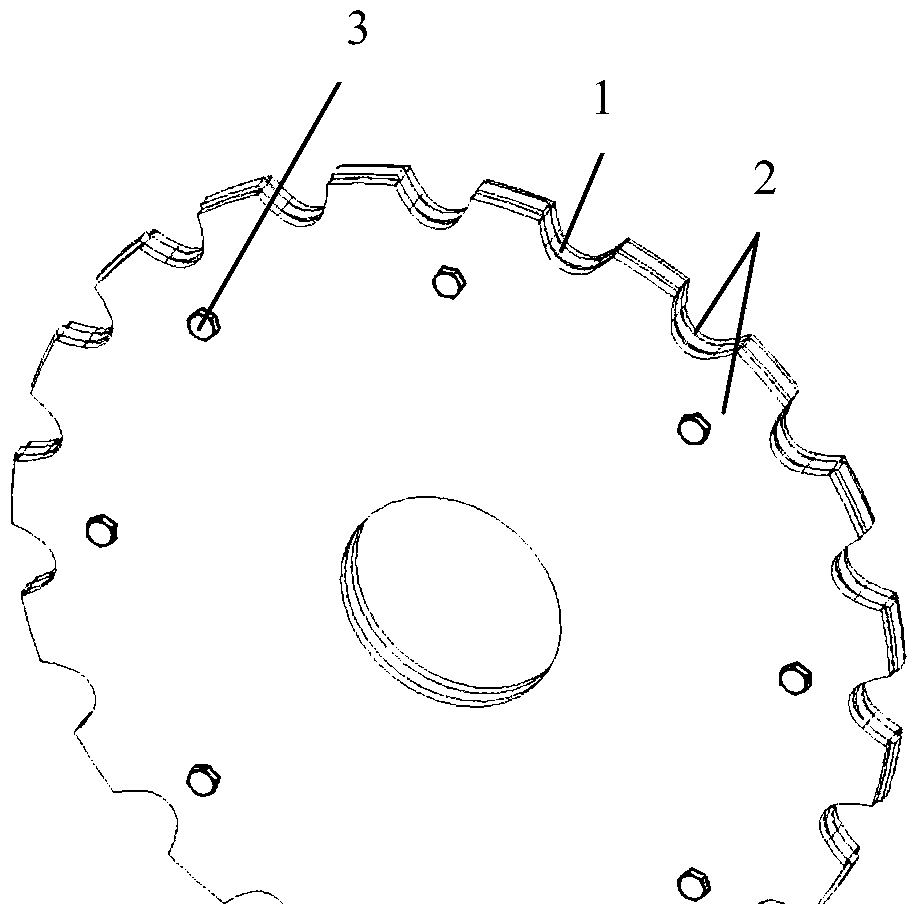

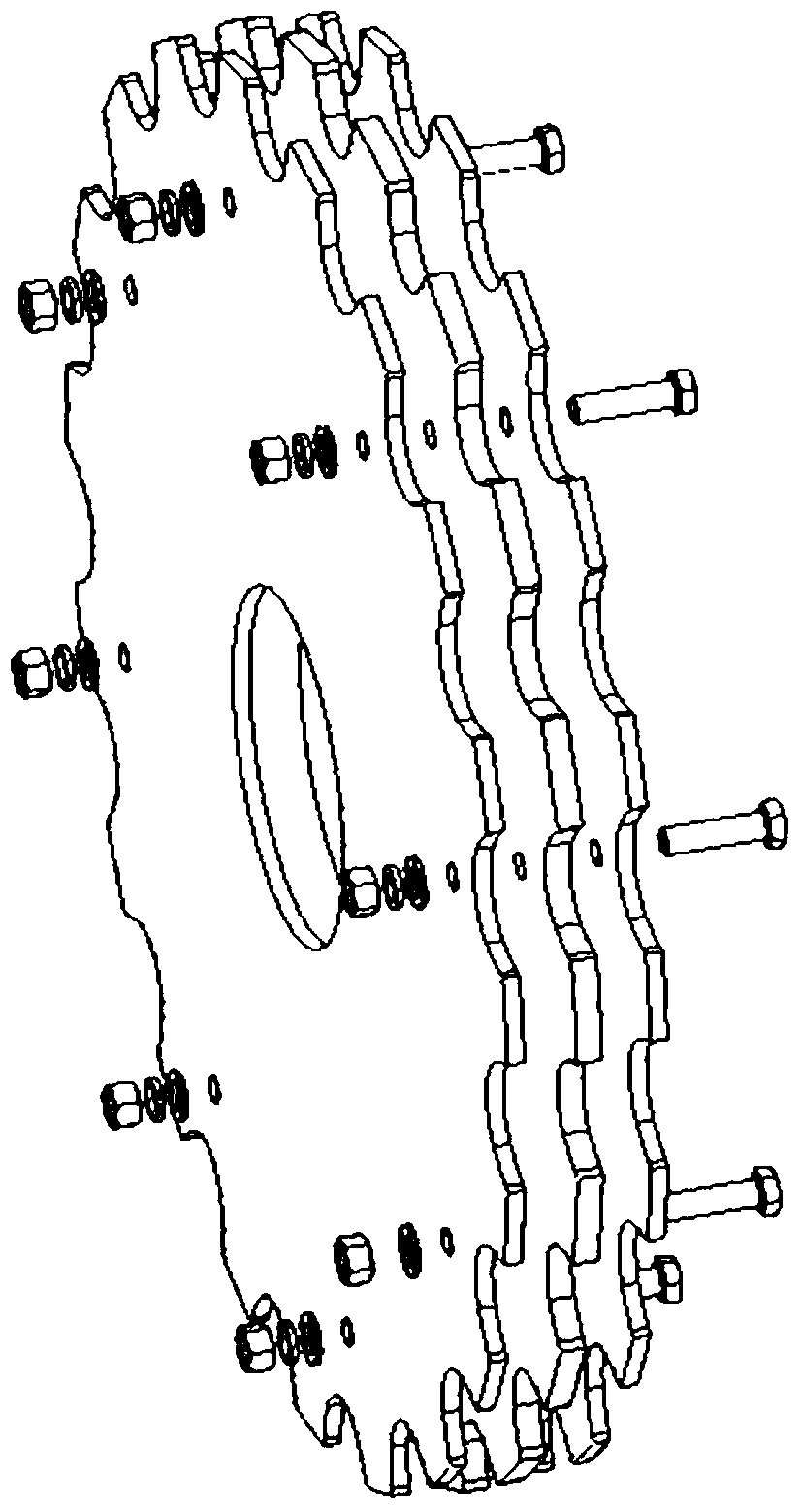

[0030] Such as Figure 1 to Figure 2 As shown, the driving sprocket used in the passenger conveying device of the present invention includes a vibration-damping sprocket 1, a reinforcing sprocket 2, and a fastener 3 for connection. The vibration-damping sprocket 1 is directly engaged with the rollers of the step chain, The meshing is stable, so as to achieve the effect of vibration reduction and noise reduction; one side or both sides of the vibration reduction sprocket 1 is fixed with a reinforced sprocket 2, and the reinforced sprocket 2 is used to ensure the strength of the sprocket; the vibration reduction sprocket 1 Mounting holes are respectively opened on the reinforced sprocket 2, and are fixed into a whole by axial connection and fixing of multiple fasteners 3 arranged in the mounting holes, so as to meet the load requirements of high lifting height and heavy-duty public transportation occasions;

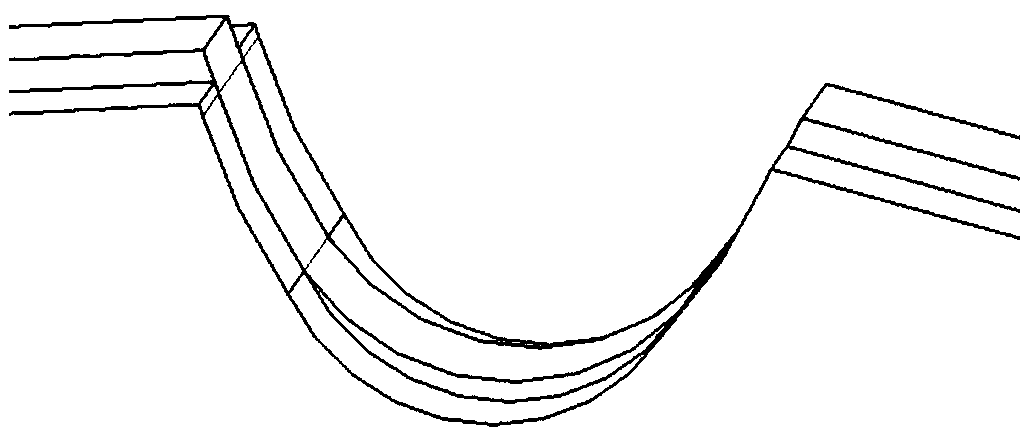

[0031] The shape of the sprocket of the damping sprocket 1 is designed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com